Posted by Simon Micklewright on 22/03/2023 20:10:40:

Thanks Dave, yes as a newcomer to lathes and such accessories I am struggling to find the correct question. As time goes by and I read more the question does indeed change.

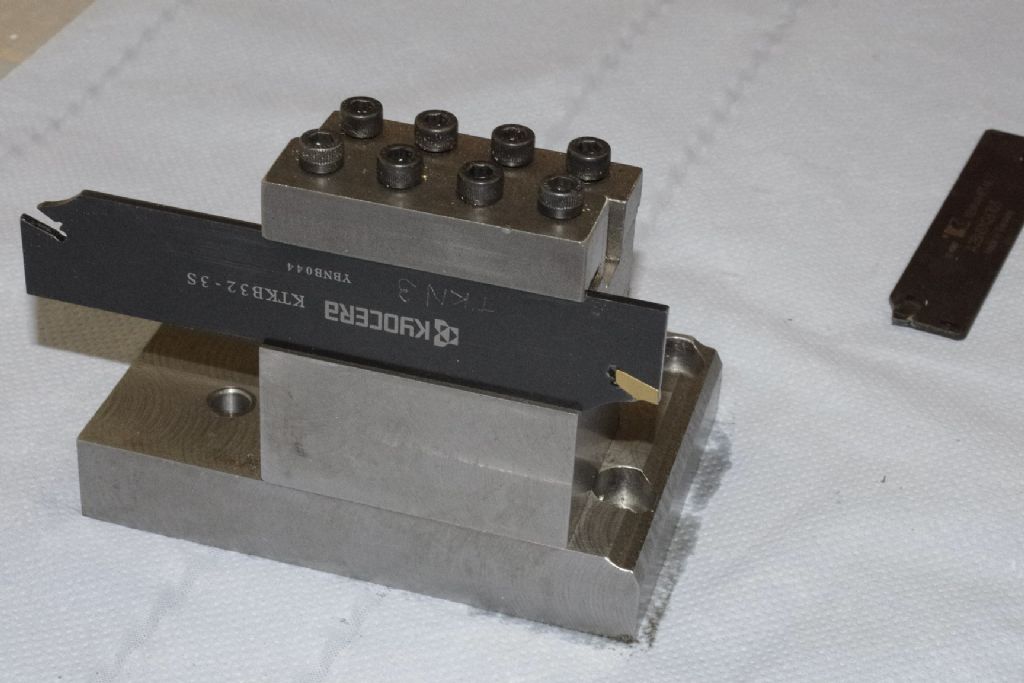

so the Taig tool post is the same as the rear tool post?

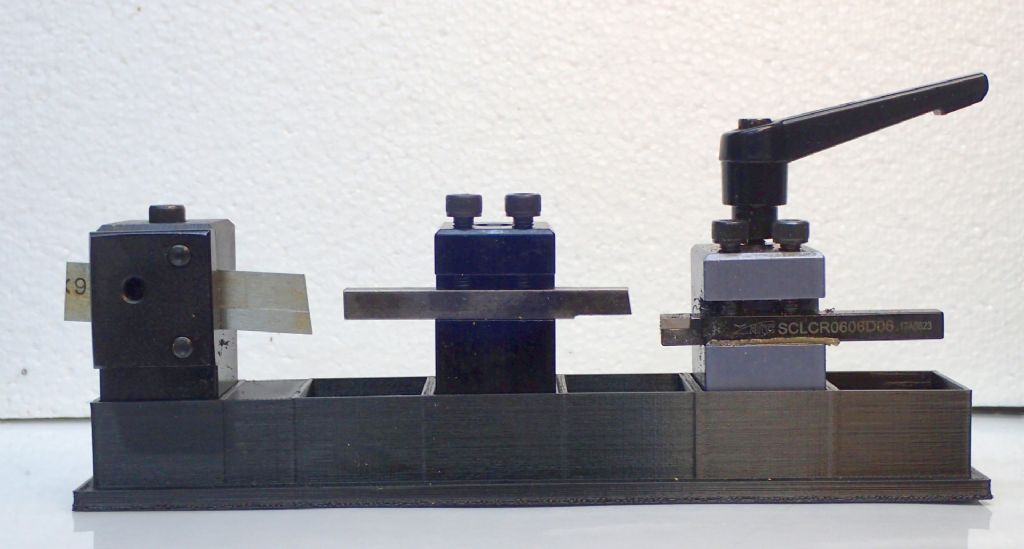

unfortunately the uk supplier does not have the front tool post in stock but does have the rear version.

they do look identical to my eyes.

Yet the price is different.

Simon,

You are learning quickly! Yes, your opening question was far too open-ended. Simplistic, even.

That you soon ‘admitted’ to the size of your lathe was a very necessary piece of the jigsaw.

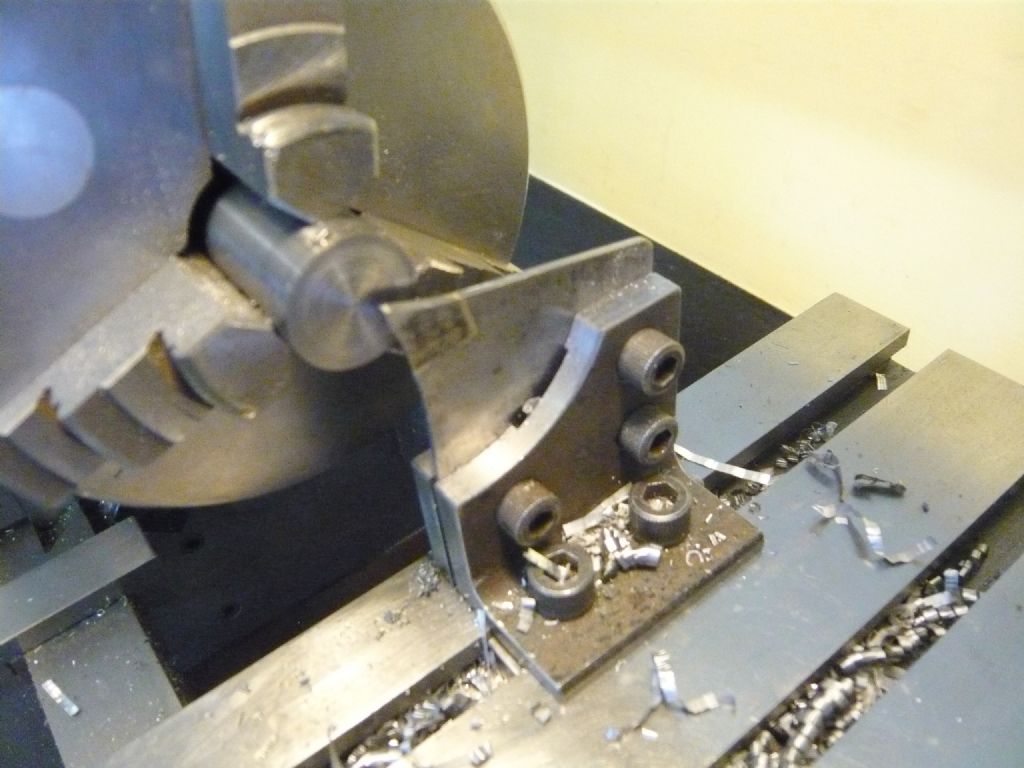

Be careful with what you see on the ‘net. That pic, reproduced from a Taig advert(?), is absolute trash, if seen by a beginner and taken as normal. Taig would, no doubt, claim that neither of the cutters were near contact with the work piece, so nor would the centre support be necessary. Obvious to anyone with experience but to a complete newbie it may give the impression that tailstock support was not appliccable to that cutting scenario. 100% wrong, of course!

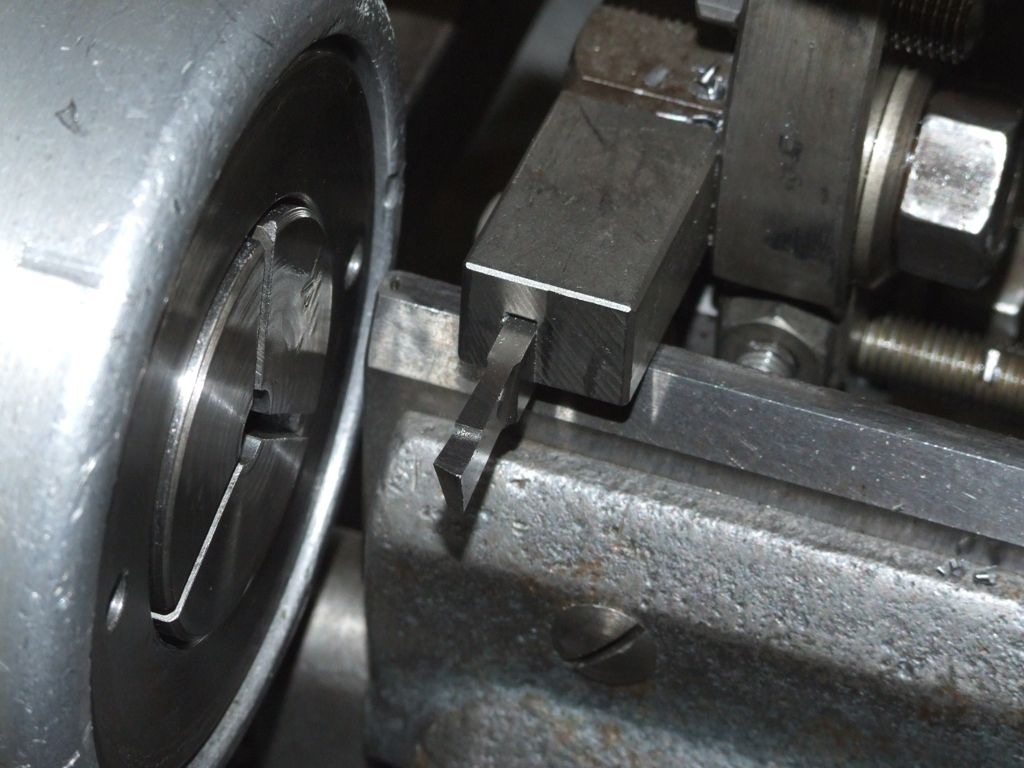

Light-weight lathes benefit from a rear parting tool. So do older middle-weight lathes which may have signs of wear developing. Solid/rigid larger lathes can cope better without (but might be better if wear is apparent). Truly commercial lathes were likely dumped/changed out if the wear was affecting the machine’s output/accuracy – and, of course, some of these have filtered down to the hobbyist.

Your lathe may be regarded as a ‘toy’ to those with huge industrial machines and large workpieces. For a clock maker, it is (maybe?) perfectly appropriate. Horses for courses’ and all that. Right down to those that simply say don’t try to part off with it. I would add that the material being cut might influence that choice.

My lathe was a good quality lathe, when new 50 years ago (cost about twice that of the local competition back then). I consider it to still be in good condition for its age but it does benefit by parting from the rear. For two basic reasons – first it is only a 5” centre height ‘hobby’ lathe and second, I’m just a hobbyist, not a ‘proper’ machinist.

Enjoy your Taig, if it is suitable for your needs. I suspect that later you may either change it for a larger machine or retain it and purchase another, larger, machine.🙂

old mart.