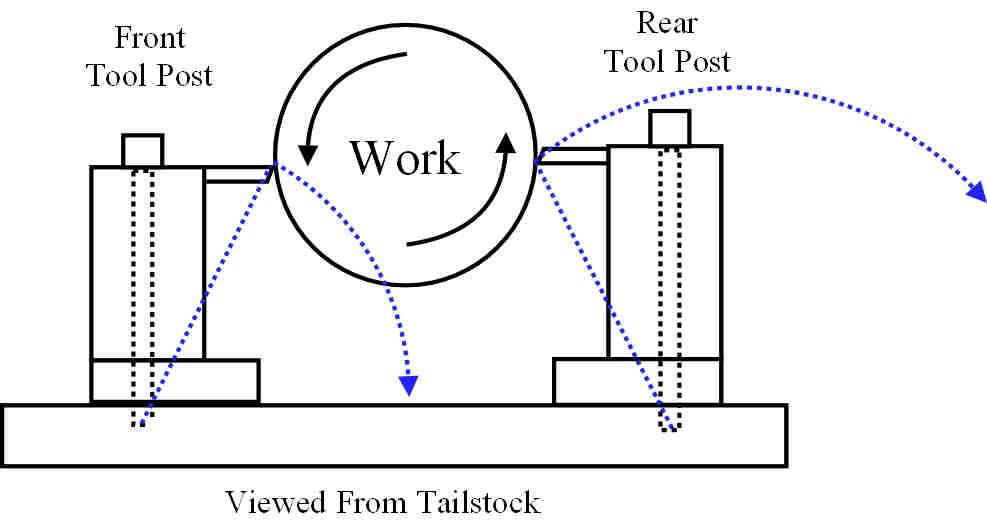

I know thats the conventional wisdom, but in fact if a tool is mounted a touch high on the front, or a touch low at the back the tendency to dig deeper is just the same, because either way its being dragged into the work.

I struggled with a couple of rear toolposts and used blades of 1/16. 3/32 and 1/8, and they were all just as darned bad as each other. (flood with coolant, cut wide slots, steep rake angles shallow rake anges and so on, front toolpost or back.) I could never, in 20 years, reach this nirvana that others seemed to, of being able to part off at high speeds and feeds.

UNTILL I bought a Kit Q cut from Greenwoods. And then looked at the geometry of that Sandvik tip, and then bifurcated with the Dremel the cutting face of ordinary HSS blades. The difference seems to be that the chip is actually rolled in on itself, so coolant gets in there and it never jams in the groove. (Nemett in ME recommended the same thing if I recall)Also with the commercial tipped blades, the carrier is significantly narrower than the tip so the back clearance is built in. Not that that is essential – one of my tipped tools is actually designed for 3mm tips, though I am using 2.5mm wide tip, and the clearance is minimal.

Since then, tipped or HSS blades, I have never had a jam up, and the days of inching in, slow speeds and extra wide slots are gone. 600rpm, front toolpost with the Dickson type holders and feed in – and the bar parts off.2 1/2″ diameter bar, single deep slot, lots of coolant, straight in, mirror finish. (TE eccentrics) I’ve parted off 3/12″ bar in a single slice, but that wasn’t an interupted cut of course.

You don’t HAVE to build a rear tolpost. I have a proper Myford one, and an Ivan Law designed one. You can have both free gratis and for nothing if they;ll fit your lathe. They really are that useful (and have gathered dust for 4 years!!) But if you want them, by all means have them, but when you fnd out how useless they are, please don’t post them back.

I suspect that the success of back parting toolposts has a lot more to do with chip clearance than geometry. Operating from the front toolpopsts should in fact be more rigid because all is being pushed down onto the bed. At the back it’s all being lifted and any slack will be magnified. And the chip clearance issue has been very effectively addressed by the modern tip shape – these tips just fold it up, roll it up and spit it out

The only thing I do is of course is to make sure that the toolposts is genuinely square to the work.

Glanze from Chronos also do a very nice tipped blade. In some ways its more versatile because it is a blade in a clamp type holder so you can keep it short for every day, and extend it when you need it. The Kit Q cut is fixed length, (but with less forward overhang) but its Sandvik tips cut more freely despite being .5mm wider.

Nobby.