Posted by julian atkins on 08/02/2016 11:12:46:

oh dear, where do i start!

1:- the box type expansion links are the most difficult type to make.

ordinary pivoted lifting links to radius rods would have been far easier.

2:- there is a particular problem in positioning the expansion link trunnions.

3:- the one piece bunker/cab side/side tank was easy to draw but awkward to make and even more difficult to dismantle.

4:- martin evans' stupid notion of making the side tank base the running boards.

5:- cylinders far too large in bore.

i can PM you re the boiler. i dont want to bore other forum members.

cheers,

julian

These are warranted points, but to be fare, the Simplex is a simple no nonsense design, yes it has its failing but what design hasn't, but its failings can be worked round or just accepted, but it has many good points as testified by the many that have been built. There is no getting away from the fact that most loco built to the design are good runners, I've seen 6 steamed at our club 4 do regular duty at open day and children's parties hauling two full carriages, the fifth I saw steamed once when it had its boiler tested, this was built by the owners grandfather and was one of the nicest finished Simplexes I've seen, the owner has since moved out of our area. The last the owner struggled to keep it in steam, and for one reason or other was unable to persist with it, if he had I'm sure that would have been a good runner also.

To take Julian's points a little further:-

1:- Terry Holland published a simplified link as part of his Farlie series of articles some time ago. Any chance of a simple sketch Julian of the pivoted lifting link design.

2:- I can only say I didn't find it too difficult positioning the trunnions

3:- Yes it is not a very convenient design, but I'm sure a two piece design could be engineered.

4:- Yes the running boards would be better split this is something I did.

5:- cylinders too large:- but they work ?.

For those building or refurbishing a simplex her are a few things that I did to mine.

1:- Added a drain plug to the bunger well tank.

2:- Added oiling points into the steam chest so that oil could be worked into the cast iron cylinders at the end of the day to stop them rusting.

3:- Drilled down the centre off the axles and drilled a cross hole so the axles boxes could be easily oiled.

4:- Cut a hole in the stretcher that covers the axle pump eccentric so that it could be oiled.

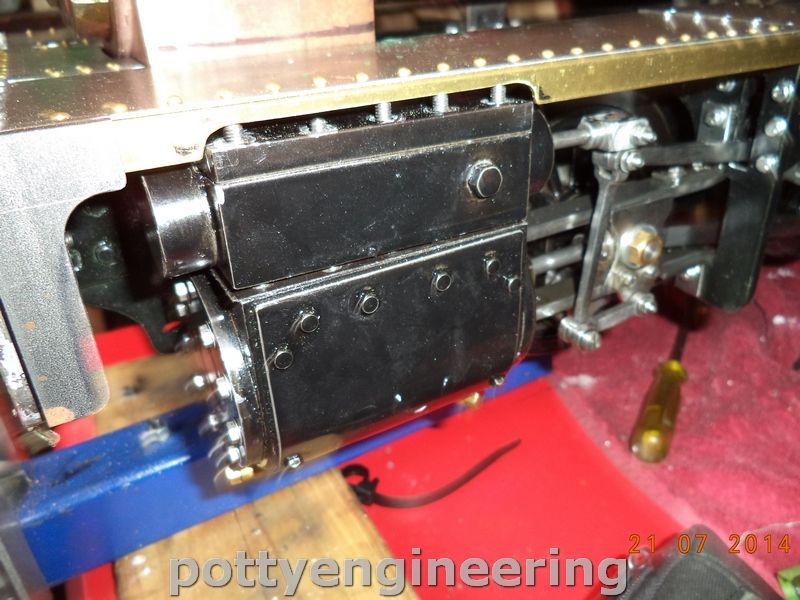

5:- Two piece running board so that the slide valves are made easily assessable.

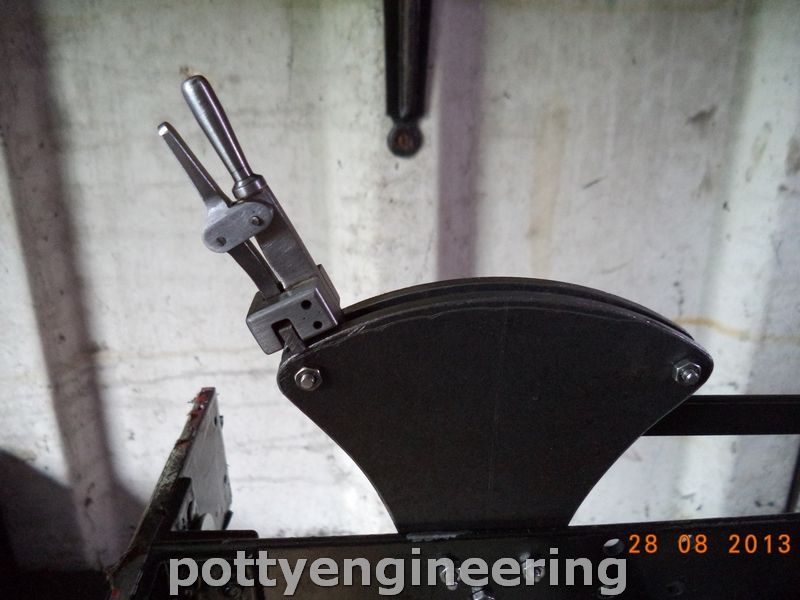

6:- Pole reverser.

7:- Curved blast pipe to direct the exhaust steam better, same with the steam pipe to the cylinders, as for the supper simplex

8:- Did away with the breaks, the drive on trucks have better breaks I couldn't see the point of them.

9:- Fitted automatic drain coxs

A wise old model engineer with many locos under his belt gave me some sound advice:-

"Its your Loco Lad that your building in your sure shed in your own time, so build it any way you want, if you don't like something change it.

Her's some picture of some of my changes.

Stew

Edited By Stewart Hart on 08/02/2016 13:21:53

David Wasson.

and had quite a hand in making a Super Simplex (larger boiler) but with the Simplex cylinder dimensions. Don Young and i had many discussions together about the original design, most of which are quite unrepeatable!

and had quite a hand in making a Super Simplex (larger boiler) but with the Simplex cylinder dimensions. Don Young and i had many discussions together about the original design, most of which are quite unrepeatable!