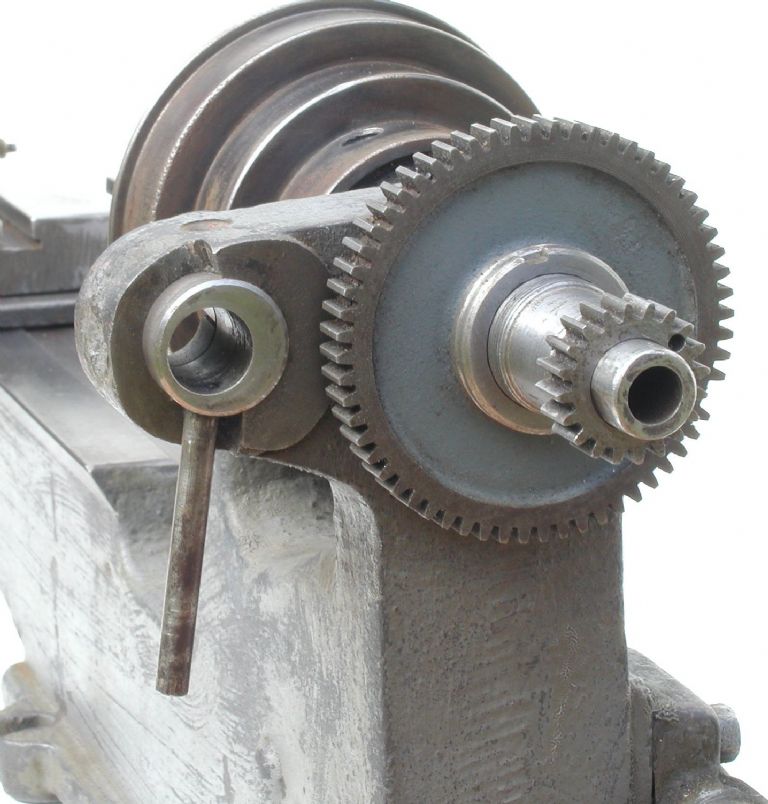

When you are searching for a gear, it is important to know the dimensions, but also the DP and Pressure Angle.

Gears with different DP will not mesh properly, if at all.

Gears with different Pressure Angles will not mesh properly.

Take a gear, count then teeth.

Measure OD of the gear in Inches (Teeth +2 ) /OD = DP.

You will not be able to measure the Pressure Angle, so you need gears of similar vintage

Modern gears will be 20 degree P A, so not suitable.

Drummond, or Myford gears will, be 14.5 degrees. Myford gears will be 20 DP. Gears for the 7 Series will have a keyway, so you will need to drill a hole, partway through for the driving pin.

In this way 7 Series gears can be used on the earlier ML1, 2, 3 and 4 lathes.

If you can find a gear of the right DP, PA and width, you may be able to modify to fit your lathe mby either boring out, or by bushing the centre.

Howard

Bazyle.

Bazyle.