Welcome. Don't be afraid to ask questions on here.

You can find out more about the lathe by visiting the Lathes UK site.

Already, you are finding out about naming the various parts of a lathe, and their function.

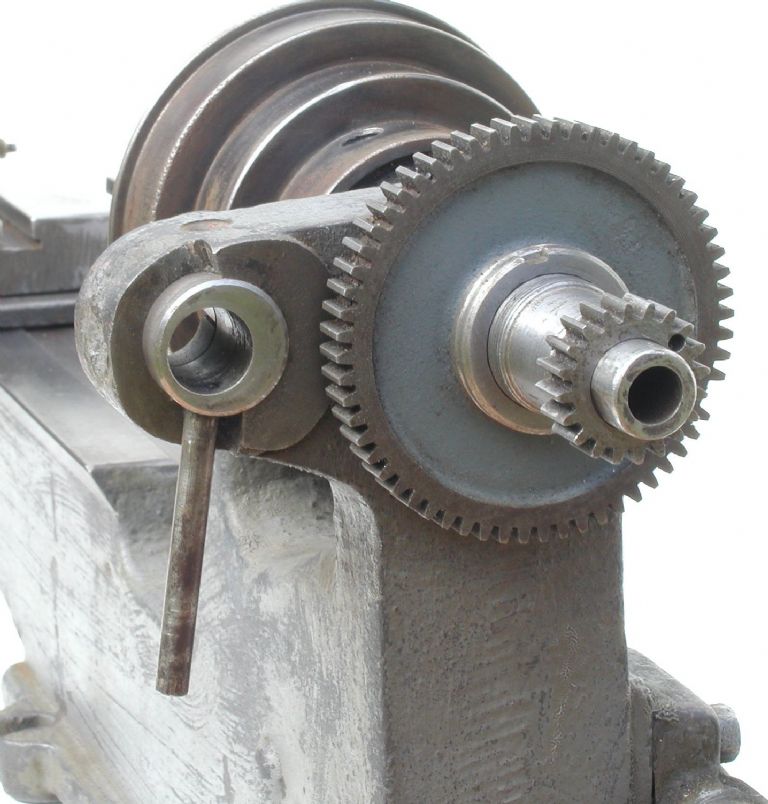

Back gear is used to slow the Mandrel relative to the incoming drive. By releasing the pulley (as you already know, by slackening / removing the grubscrew ) The pulley then drives the mandrel through the two stage reduction provided by the Back Gear.

Leaving the grubscrew in place will lock everything, since the pulley id trying to drive the Mandrel at two different speeds at the same time.

Do not be tempted to use this to lock the mandrel to unscrew a stuck chuck! That is a short cut to knocking teeth off the gears.

Changeears allow the Leadscrew to be driven at different speed from that of the mandrel, so that threads of different pitches can be cut on the material in the chuck.

The gear train required for a given thread will depend up the pitch of the Leadscrew on a particular machine.

Many (But not all! ) lathes produced to Imperial standards used a Leadscrew with 8 Threads Per Inch (tpi )

So, purely as an example, if a 12 tpi thread needed to be cut, the changewheels would be arranged to give a ratio of 1.5:1 between mandrel and Leadscrew. So the gear vtrain might be set up Mandrel 30T, to drive a 45T gear on the Leadscrew with an Idler in between. The number of teeth on the idler will not matter since it does not affect the overall ratio. The essential thing is that the mandrel revolves 1.5 turns while the leadscrew rotates for each turn of the Leadscrew.

In some cases the Idler may have to be a compound gear (Two, of different tooth counts, joined together )

But those are lessons to learn further along.

by arranging a suitably large ratio, between Mandrel and leadscrew, a power feed can be arranged to provide a fine finish.

But in early days, you need to become familiar with the controls, and how to set tools at centre height (To ensure that they cut properly ) and to operated the handles / handwheels to provide a steady feed.

Reading L H Sparey's Book "The Amateur's Lathe", Ian Bradley's "The Amateurs Workshop", Harold Hall's "Lathework", or Neil Wyatt's "Lathework" be explain a lot of things.

Being an older design of lathe, you would probably be better using High Speed Tools, usually referred to as HSS. This will then let you in for buying a bench grinder, so that you learn how to grind tools.

A set of Zeus charts will be useful. You will refer to them often (I still use mine, bough as an Apprentice in 1958 )

Another book that you may well come to find a useful reference is Tubal Cain's "Model Engineers Handbook"

When you eventually come to cutting threads with Taps and Dies, yo will find No 12 in the Workshop Practice Series, "drills, Taps and Dies" helpful. For this work always use a cutting lubricant such a Trefolex or Rocol RTD, and back the Tap or Die every half turn, to break the swarf; rather than the Tap! taps break through bending rather that excess torque (But if gets tight, back off anyway )

Find a Model Engineering Club near you, if possible, and join. In this way, you can get face to face advice, and possibly demonstrations.

HTH

Howard

Michael Kibby.