Thanks for replies to my questions, and also for the interesting general discussion of lathe power feed. The reason I asked is that I am trying to make better use of carbide insert tooling than I have been, and thought I should try to understand the whole business of speeds and feeds better than I do.

It seems that it is normal for surfacing feeds to be slower than sliding feed for a given gearbox setting, but not by as much the factor of five on my machine. I'm glad that there is no suggestion that surfacing is fundamentally different turning – that would have worried me! It seems that it's just fitting gears into the available space.

The comparison with Andrew's M300 was especially interesting as (according to the late John Stevenson who installed the machine for me) the Far Eastern 12×36 lathes are (loosely perhaps) based on the M300. There are clearly big differences though – Andrew's machine has a factor of two rather than five between the sliding and surfacing feeds.

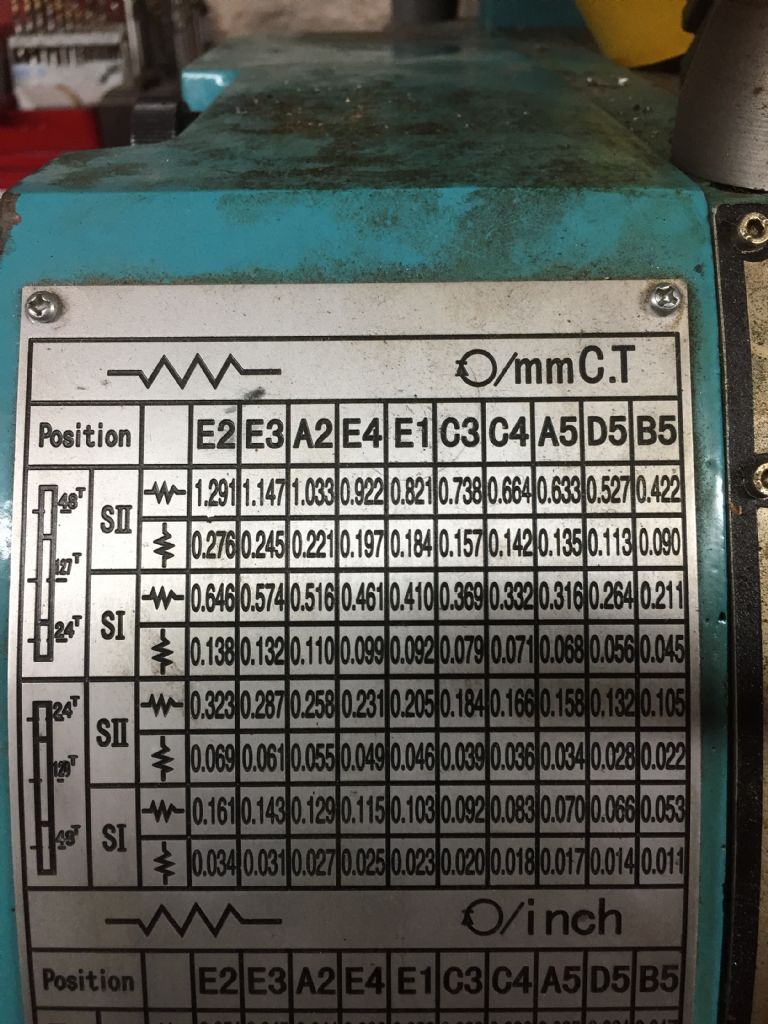

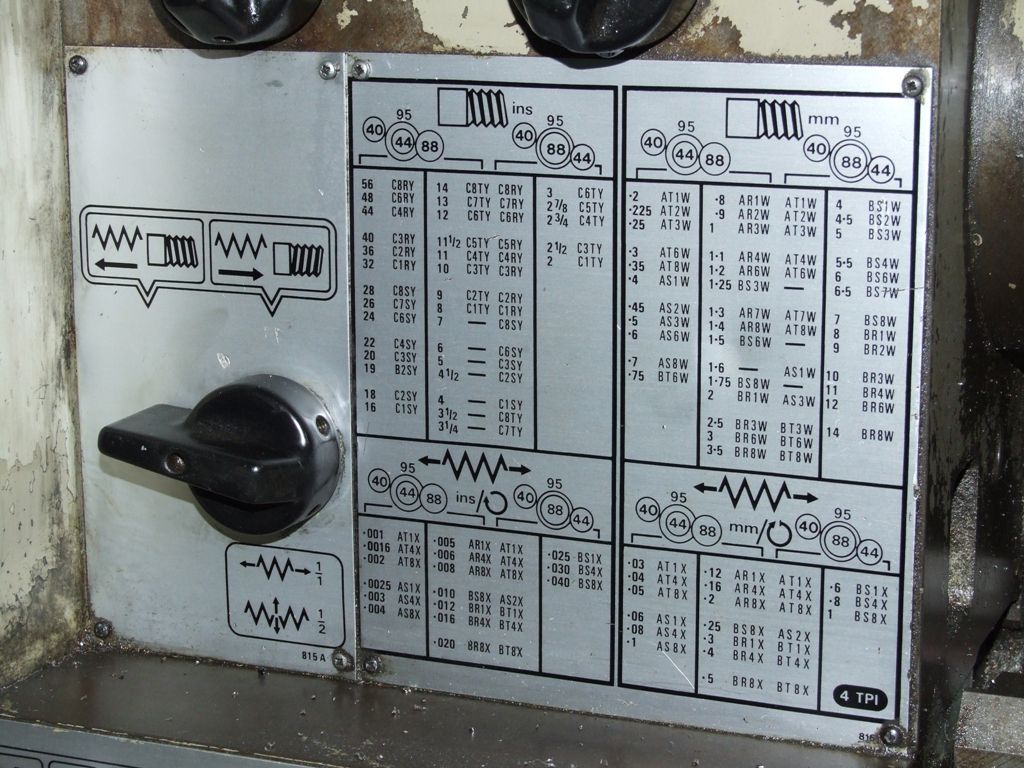

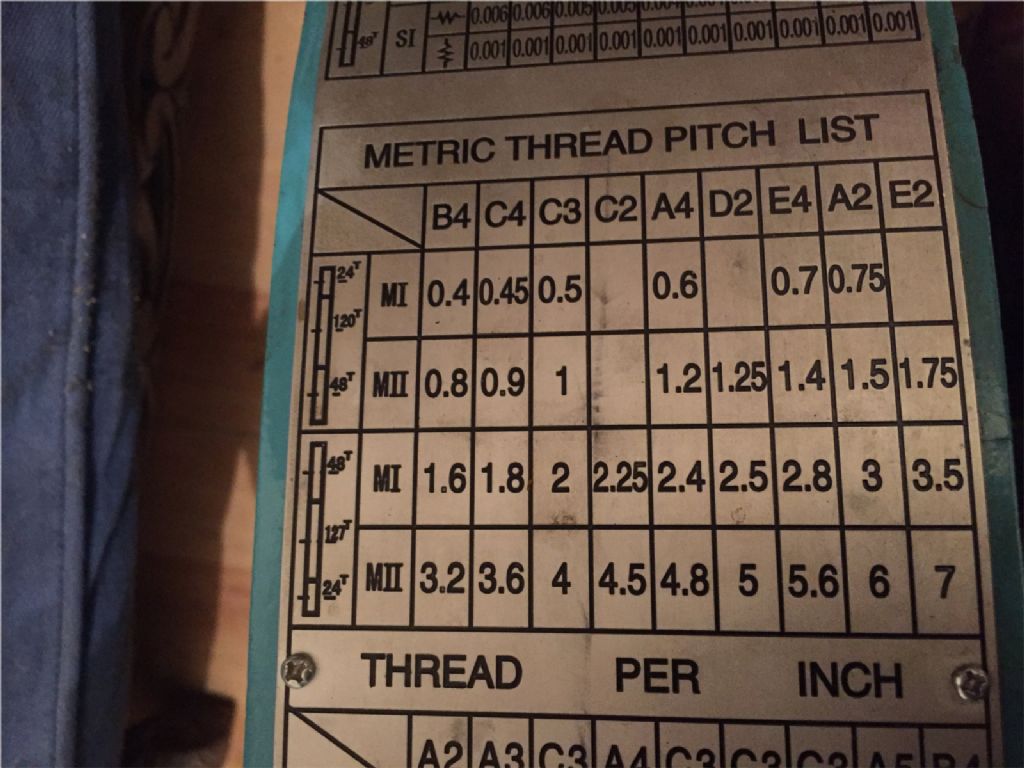

This is the plate on my lathe's headstock:

A somewhat bewildering array of possibilities!

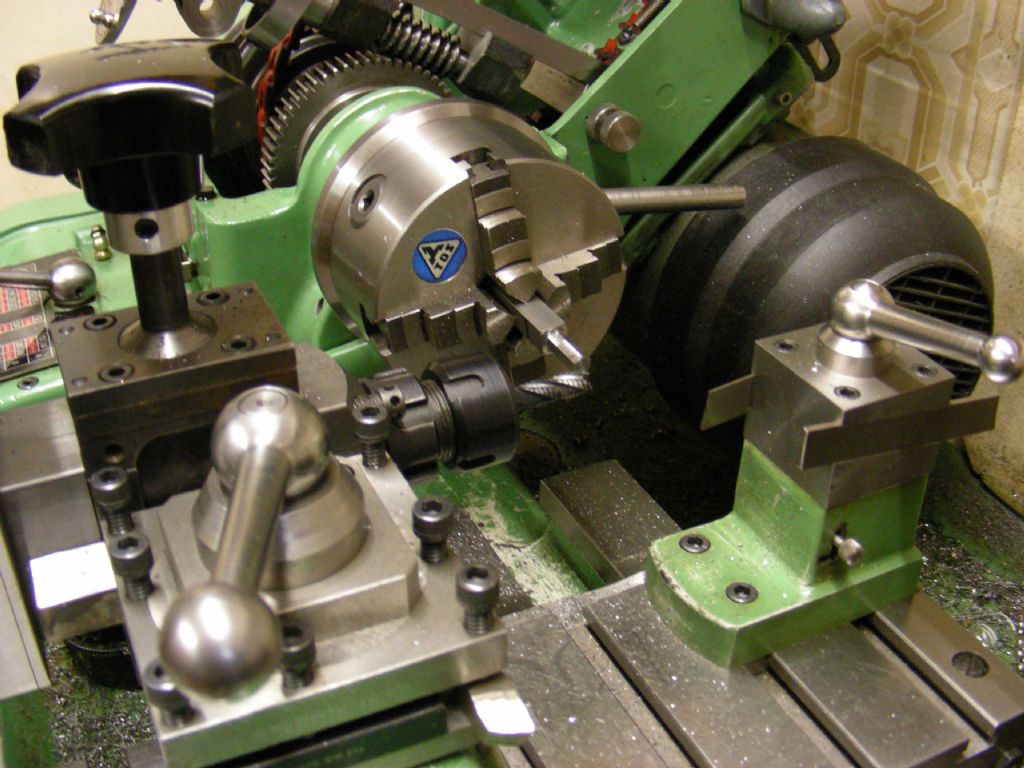

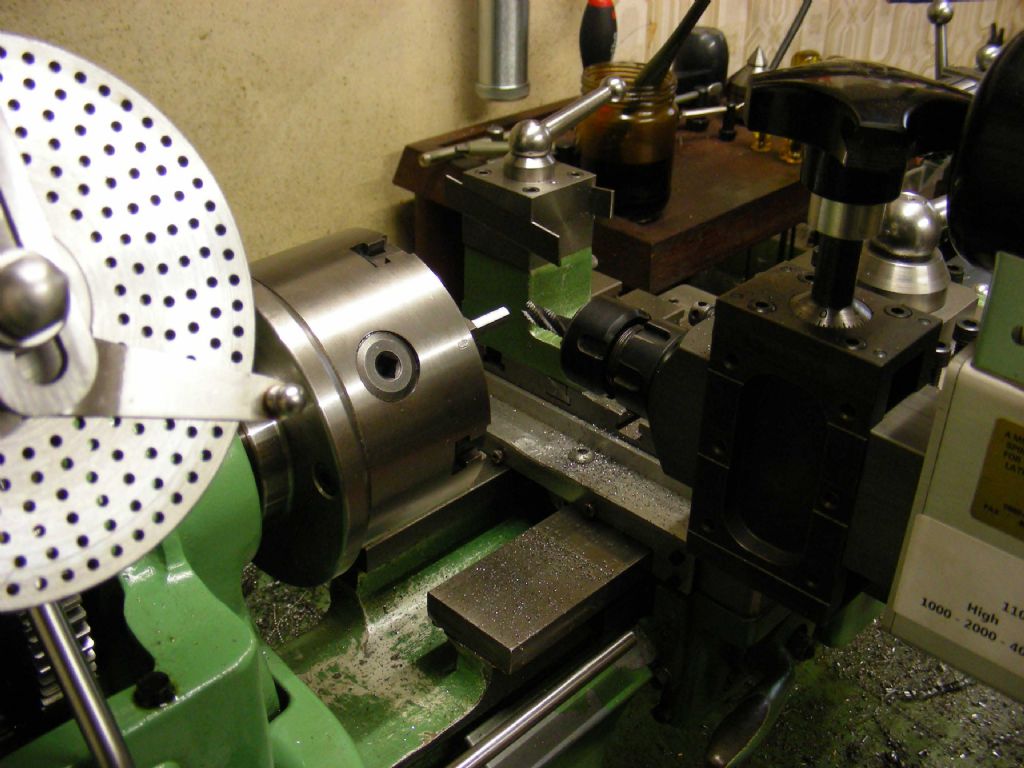

I had a look at the lathes.uk article on the M300 and am now wondering if if the difference is to do with the external gearing between the spindle gearbox and the drive box. On my lathe it looks like this:

That's with a 48T on the output from the spindle box and 24T on the input to the feed box – the upper half of the chart above. The alternative is to reverse them, which slows the feed by a factor of four. Maybe this is something to do with it – it seems different from the arrangement on the M300 as far as I can tell from lathes.co.uk.

It was also interesting to hear that Andrew's lathe is 'power limited' at 3HP (if I remember right – apologies if not). My own machine is 2HP, so even more so, but I've never felt close to slowing the motor. So perhaps I can push harder.

Robin.

Robin Graham.

cross-feed speeds is remarkable.

cross-feed speeds is remarkable.