Tricky question, because it bears on the state of metallurgy and the ship-building methods applied by Harland and Wolfe in 1908.

Metallurgy was far from perfect! Contemporary magazines like ‘Engineering’ contain many complaints of poor steel quality, such as ‘plates that shatter like glass’. The Bessemer Process revolutionised mild-steel production, but the product was inferior to modern steels because the purifying blast was done with compressed air, nearly 80% Nitrogen, which didn’t clean fully, and left Nitrides behind in the steel causing brittleness. Cured later by blowing with pure Oxygen and by eliminating impurities by detecting and removing them chemically, a process that took decades. But in 1908 steel quality varied mysteriously because the raw materials weren’t pure and the chemistry wasn’t fully understood. Further, the science of the day had only touched on the effect of low temperatures on metals, which turned out to be significant.

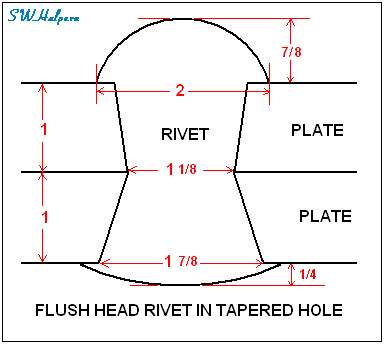

And in 1908 shipbuilding was dominated by riveting plates to girders and columns. This type of structure is rather weak and excessively heavy, difficult to keep watertight, and the rivets are weak in shear. Shear strength matters when a plate is struck a sideways blow, or the rivet head is over stressed upwards, as might happen when a plate is dished by hitting a rock. It’s possible for seams to break completely open, or for a blow to cause multiple small leaks by popping or stretching rivets during a collision.

Mostly likely cause of the Titanic sinking was about a third of the submerged hull being scraped at high-speed along an iceberg weighing much more than the ship! Didn’t create a single massive hole, rather a line of serious leaks that bypassed 5 or 6 bulkheads and couldn’t be controlled. Then it didn’t help that the bulkheads were open at the top, allowing flooding to spread into undamaged compartments as the bow sank.

It’s been suggested that itanic would have survived had she hit the iceberg head-on. She was designed to do that, allowing the bow to fold, and protecting the bulkheads further back. Up to 3 flooded compartments were survivable, not 5 or 6.

The collision occurred during unusually cold weather, so the hypothesis that steel-plates and/or rivets were weakened by brittleness isn’t daft. And if they failed prematurely during the collision, the leak would have been bigger than otherwise, perhaps ending all hope. However, although they might have made the situation worse, brittle rivets didn’t sink the ship!

As the disaster occurred in modern times, the Titanic’s construction is well documented. Tom McCluskies “Anatomy of the Titanic” is worth a read. Thus we know that the ship was built with Wrought-Iron rivets, not mild-steel, and which sizes and head types were used in each section. Briefly, the shell was held to the frames with pan-head, flush point rivets, that is the outside of the rivet was hammered fairly flat to the plate, as Steven’s diagram above shows. Looking at the photos, long-shots of the lower hull don’t have obvious rivet heads, but close ups show them distinctly rounded above the plate. I don’t think exact shape would make much difference in this accident – when a 50,000 ton liner swipes an iceberg, the entire structure bends.

Wrought-Iron was made from Pig-Iron, not Cast Iron. Pig-iron is poor stuff full of slag (mostly silicates) but repeatedly turning and hammering it tended to beat the slag out, improving the Iron whilst imparting a grain structure like wood. The best Wrought Iron is about as strong as mild-steel, but only along the grain. It forges and welds easily and resists corrosion. On the down side, very expensive to make, difficult to machine and the quality is unpredictable. It improves the more it is reheated and beaten, more art than science.

Thirty years later several Victory ships fell apart due to low temperature brittleness during WW2. A combination of problems: making the ships from a mild-steel that was low temperature sensitive; squaring off hatchways etc as a welding opportunity introduced stress raisers; and then the ships were routed far north into the stormy Atlantic to avoid U-boats. The pictured example broke in harbour, others weren’t so lucky!

We can’t know for sure exactly what happened to the Titanic. The US Inquiry was a politicised shambles that failed to ask the right questions, and the British Board of Trade Inquiry didn’t do well either! Concentrating on blame and emotion rather than the technology left the door wide open to conspiracy and other theories. The NIST report is more credible than most though.

Dave

Nigel Graham 2.