Posted by Izack Madd on 07/10/2016 10:58:57:

Posted by SillyOldDuffer on 07/10/2016 10:49:09:

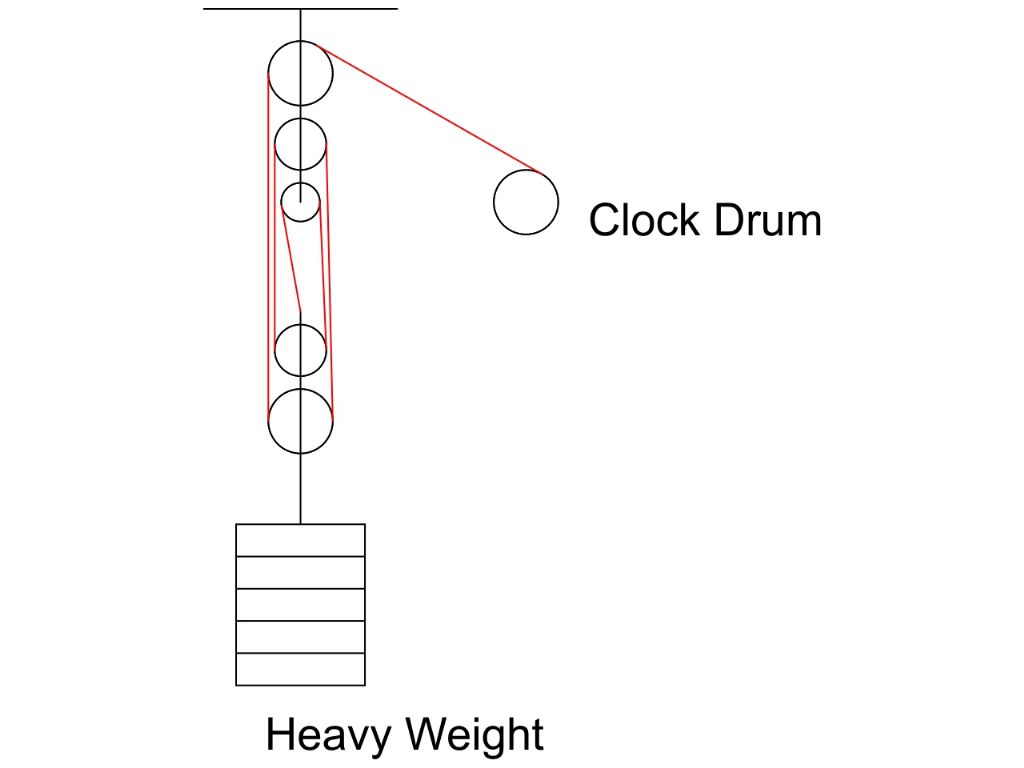

Any reason why Izack shouldn't use a pulley system arranged 'in reverse' and suspended from the ceiling like this?

Proportionally more weight will be needed to maintain the pull on the clock drum. It will be necessary to add a significant allowance for friction. (5 pulley axles!)

Dave

This is approximately how it was envisaged with the gears between the pullies and the drum. And as the drum onlyhas to turn at a speed of 1rpm and the weight has a potential speed of 32 feet per second even reducing that by a factor of five still gives me 6rpm. And a pulley ratio of 4:1 so I'd have four times the travel and enough speed. And by gearing down as with a cars gear box I'd increase the force enough to turn the other gears in the clock. Or so I thought.

I find the relationship between energy, force, work, speed and torque confusing!

In this case, the way I look at it is:

- You need sufficient force on the clock drum to turn the clock's mechanism. The force will be provided by a weight. As the clock regulates its speed you don't have to worry about speed, you just need to provide enough pull or 'weight' on the clock's winding drum. You know what the clock weight is.

- The pulley system has a ratio that could be used to extend the distance that a new winding weight will fall. This will make the clock run longer between rewinds, provided the clock drum is still pulled hard enough to work the mechanism.

- Assuming a frictionless 4:1 pulley system, increasing the effective length of the drop by four will also have the effect of reducing the effective weight at the clock by a factor of four as well. So the pulley weight has to be 4 times heavier than the original clock weight in order to provide the same 'pull'.

- As a real pulley system is far from frictionless, the pulley weight will probably have to be distinctly more than 4 times bigger. 6 times feels more like it, but you'll probably have to experiment to find a pulley weight that keeps the clock going consistently/

Your original proposal to use gears to restore torque reminded me of the way transformers are used in power distribution systems to step voltages up and down. As such I initially thought it might work, but that was due to me ignoring the fundamental restrictions that forbid perpetual motion.

Good luck with your clock,

Dave

Neil Wyatt.

Neil Wyatt.