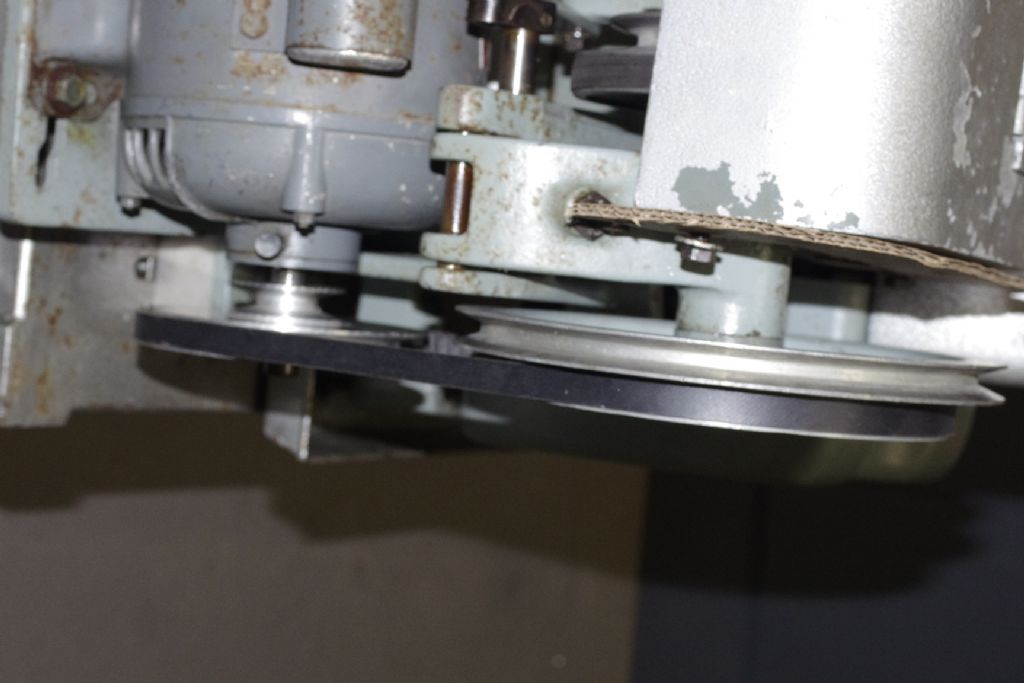

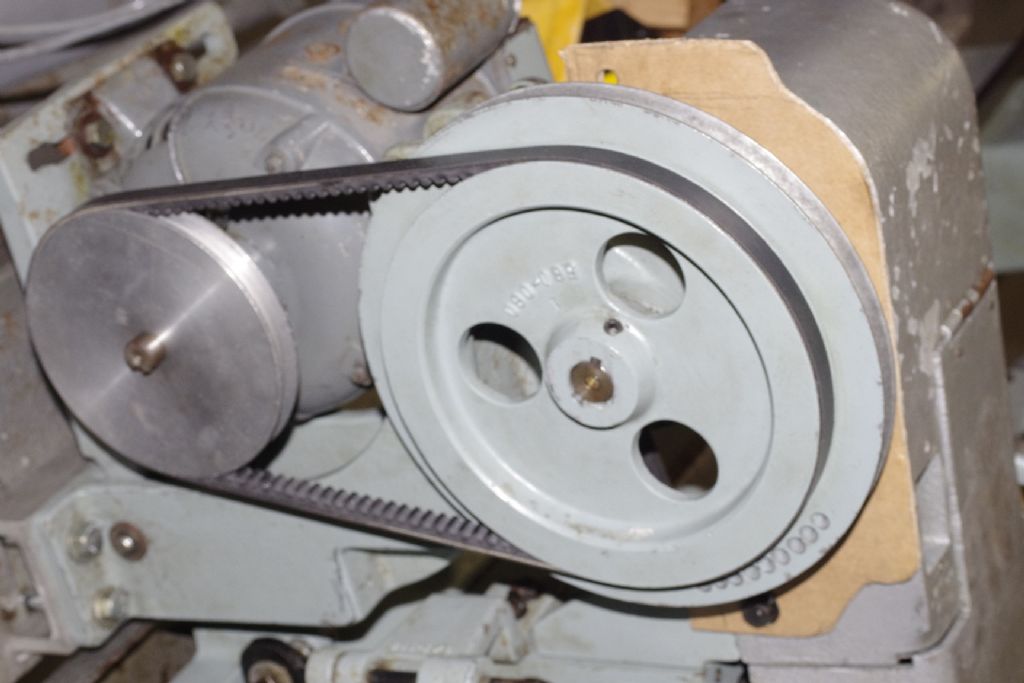

I get the impression that the whole set of speeds for this lathe will be from 10 to 20% faster than they should be. The guard door is having to be lowered and moved rearwards to clear that 5 1/4" motor pulley. Fortunately there is plenty of clearance around the upper 7.5"-9" pulley to do this. The motor is in working condition to test the range of speeds, the last owner had simply fitted a plug to the cable from the motor. Not exactly my idea of a proper way of running a machine tool.

I could keep the 2" pulley and reduce the 5 1/4" as the motor pulley is one piece and machined from plate, not a casting. It would be easy to mount it on a faceplate if some tooling holes were drilled in it.

The list of options available to me has now reached three. I am starting to lean in the reduction of the larger motor pulley size as suggested by Robert, as being my easiest solution.

More measuring will be done tomorrow.

Edited By old mart on 18/06/2021 20:33:14

Edited By old mart on 18/06/2021 20:35:45

Edited By old mart on 18/06/2021 20:38:16

Edited By old mart on 18/06/2021 20:55:59

old mart.

rt,

rt,