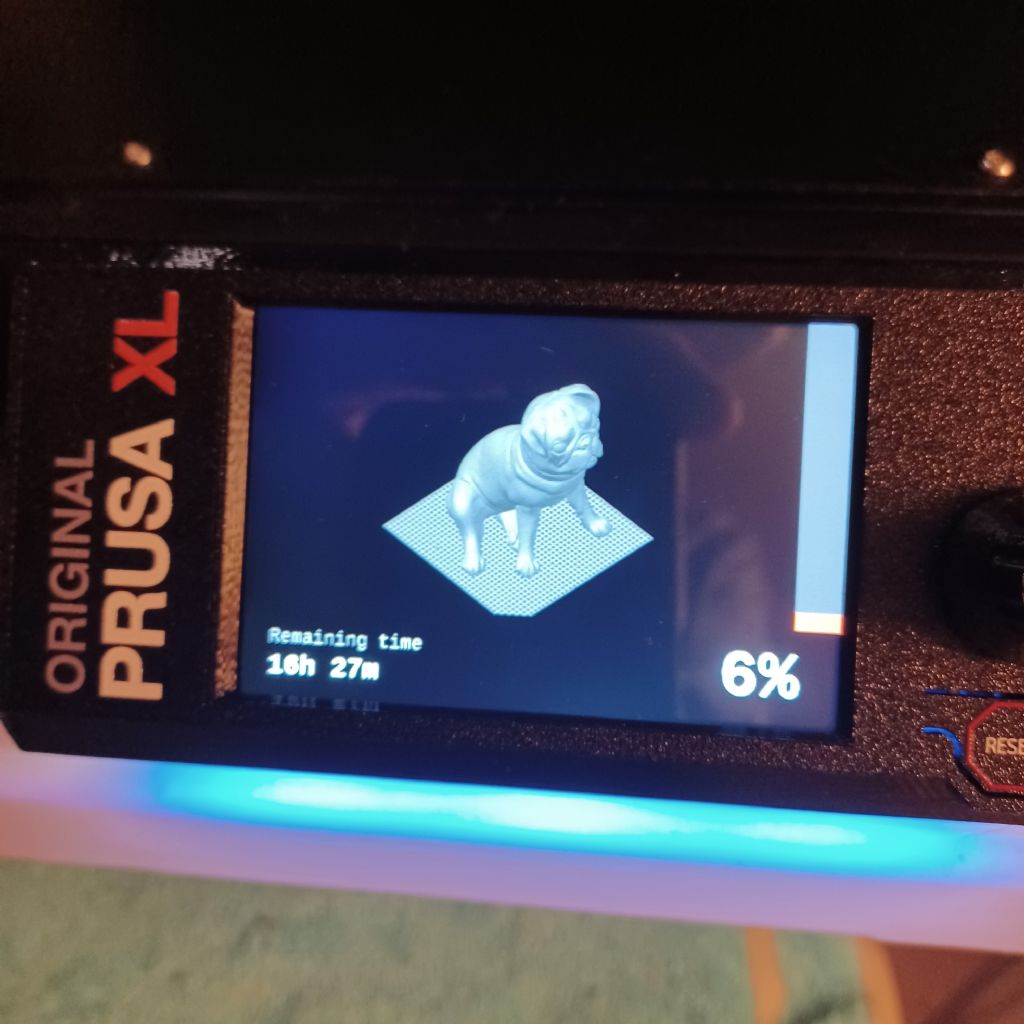

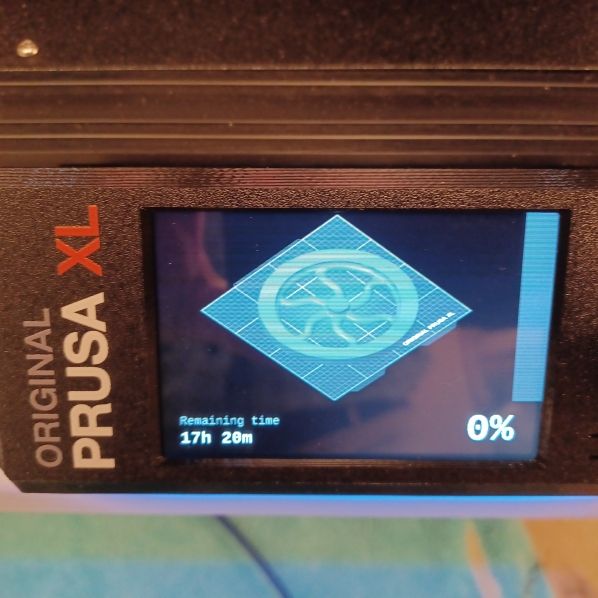

I purchases a new Prusa XL 3D printer the other day, after being on a waiting list for perhaps a year.

While I don't have much time to use it yet, the reason I went ahead and ordered one immediately after getting an announcement is that Prusa has had severe supply chain issues, and continues to have issues, and so first days orders take a year to ship.

I figured if I waited, the delivery could be years away.

A quick review of the machine in some online videos seems to indicate that many/most folks seem to be very please with their XL's (the few who have been lucky enough to snag one).

I have tried a few prints on the XL, and I must say it seems to be a very stable machine, with no first layer adjustment required, and so far no bed lifting issues like I have had on other machines.

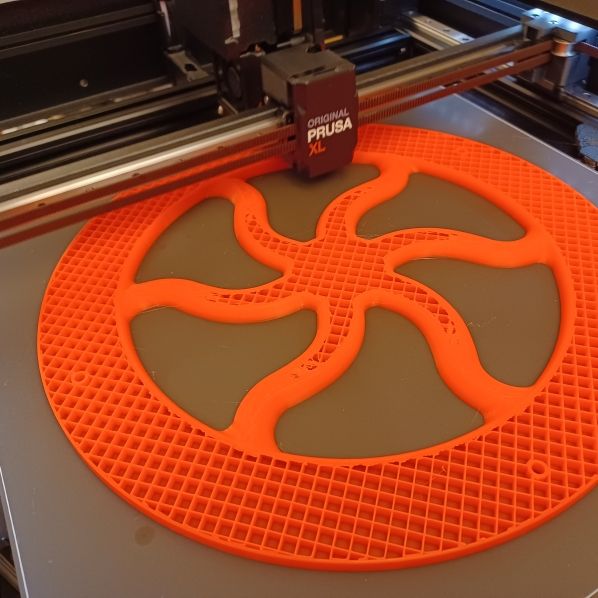

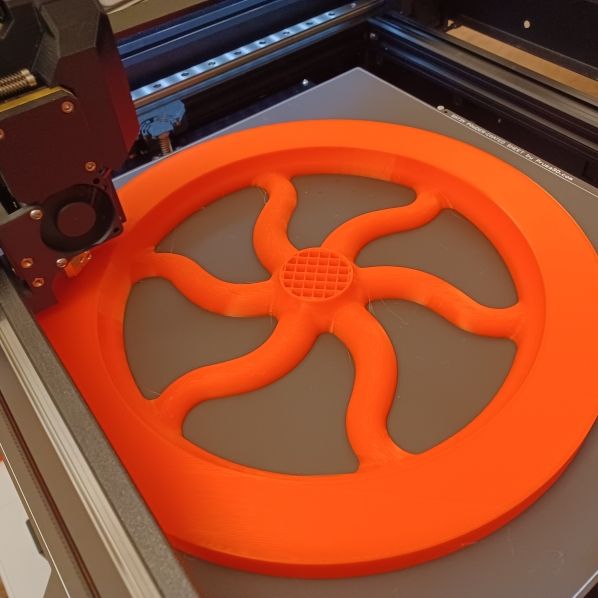

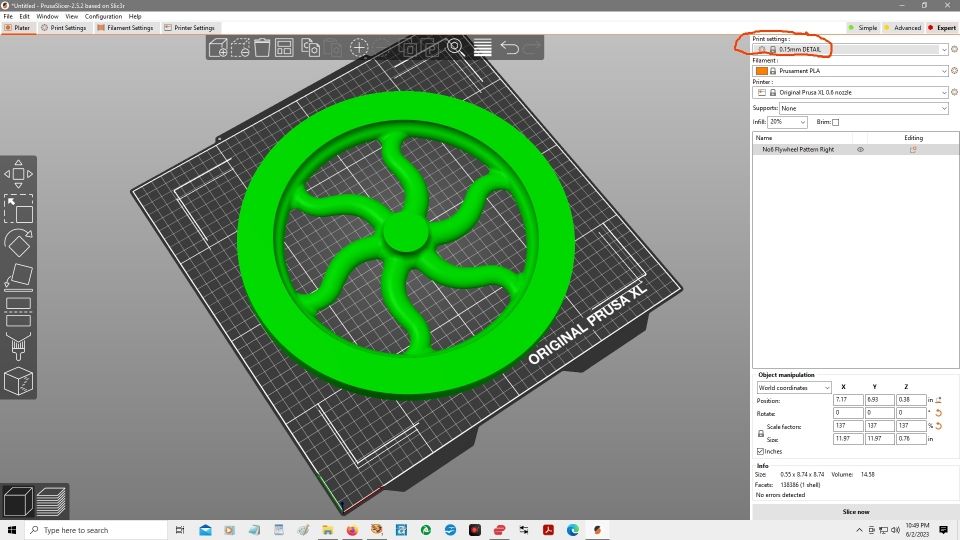

JasonB has provided a magnificent flywheel pattern in 3D to me to use as a test, and I am very impressed with his design.

Jason's flywheel pattern halves printed well with no problems.

I had hoped for slightly better surface finish, but overall I am very impressed with the XL.

Print area is 14" cubed, so best to stock up on filament for this printer.

Pat J

Anonymous.