Following on from the discussion in Vice Upgrade I've decided to take John and Jason's advice and install a bar into the bottom of my K4 Vice. The K4 already has a mounting slot for such a thing, so in theory at least, we're already half way there (removes tongue from cheek)! Fortunately, the slot is exactly the same width as the slots on my Super Major Milling Machine (13.8mm).

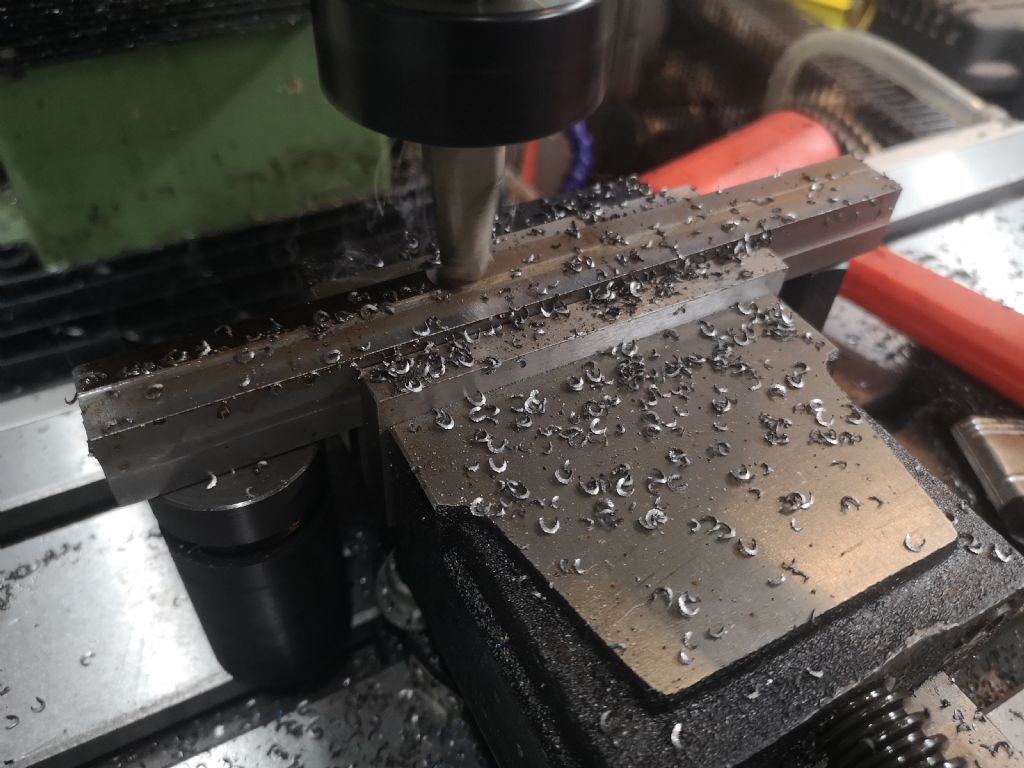

Squaring up a piece of 20mm x 20mm square bar I found in the shed:

Slicing off 5mm in the bandsaw (massive time saver):

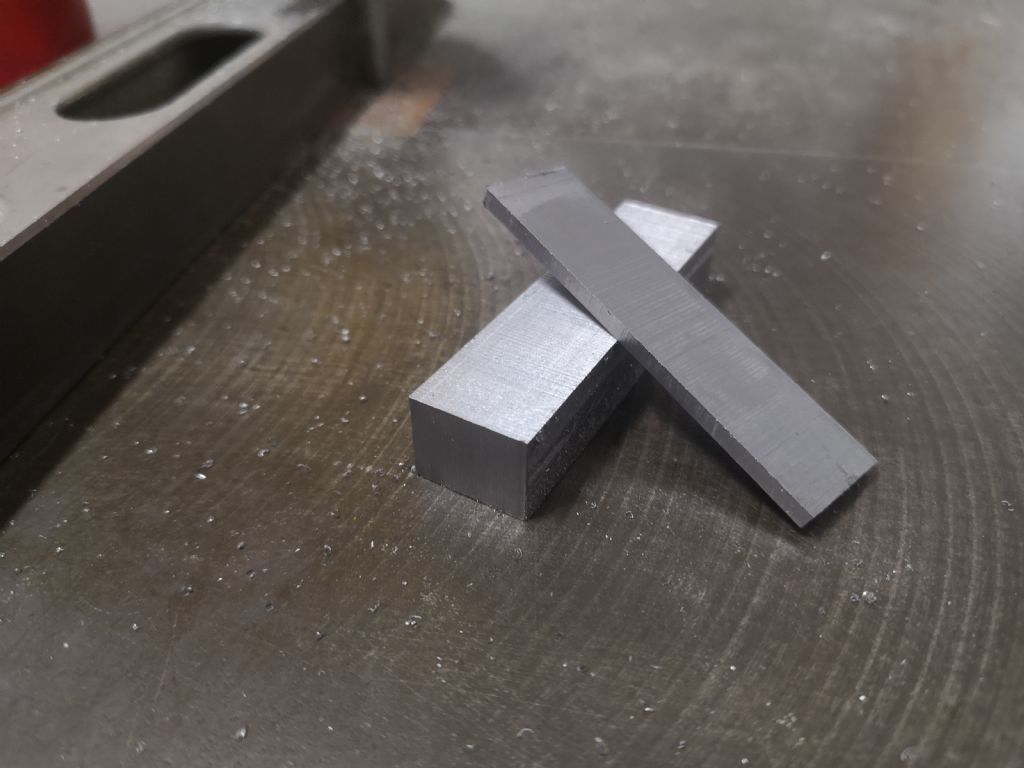

After milling to size and chamfering, the bar fits perfectly into both slots:

Counter-bored holes for the M5 fixings:

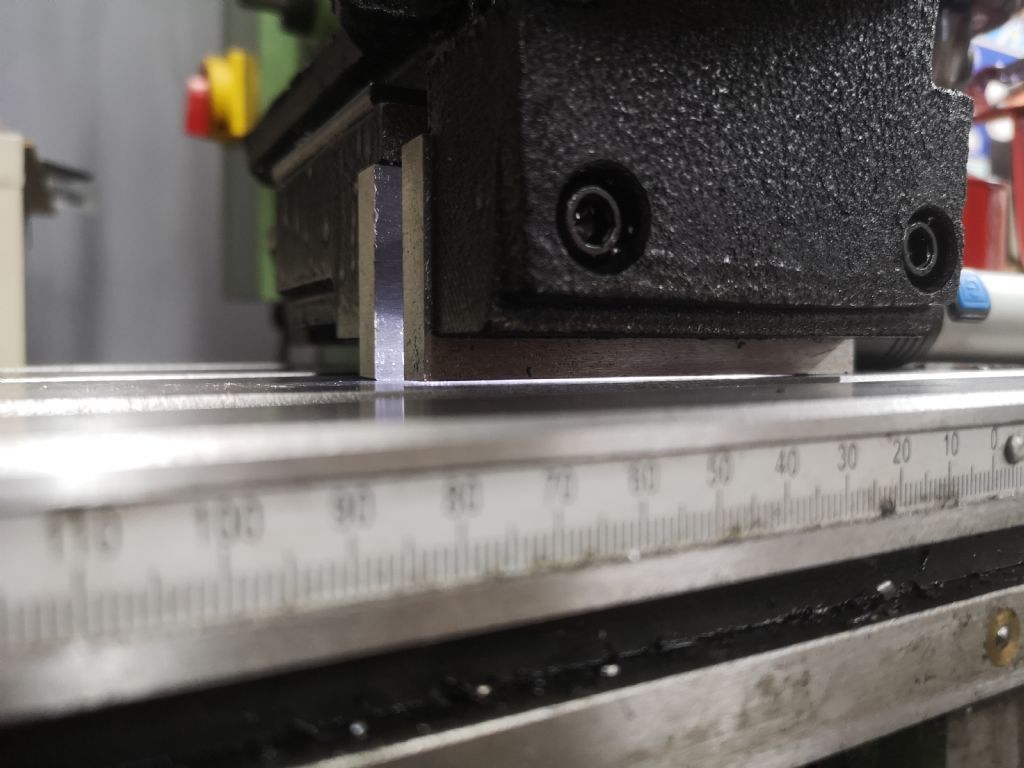

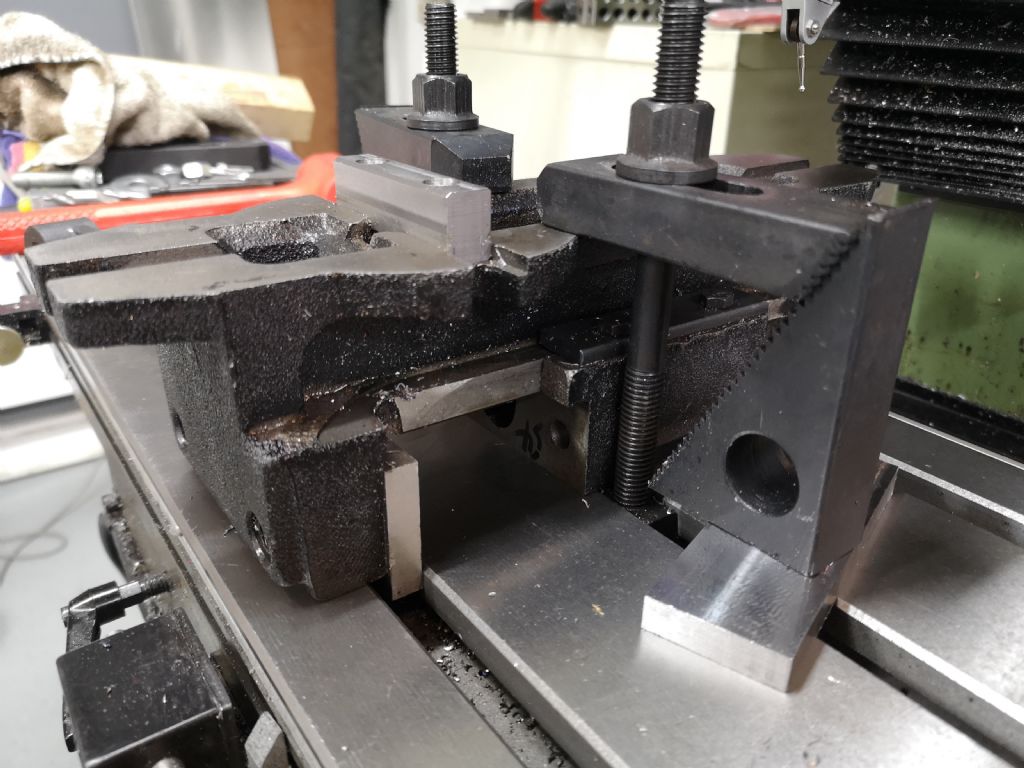

So far, so good:

The bar fits very snugly into both the vice and table t-slot with no movement.

However, once fitted tightly to the table, a quick run up and down with a DTI showed 0.2mm run-out over the width of the jaws.

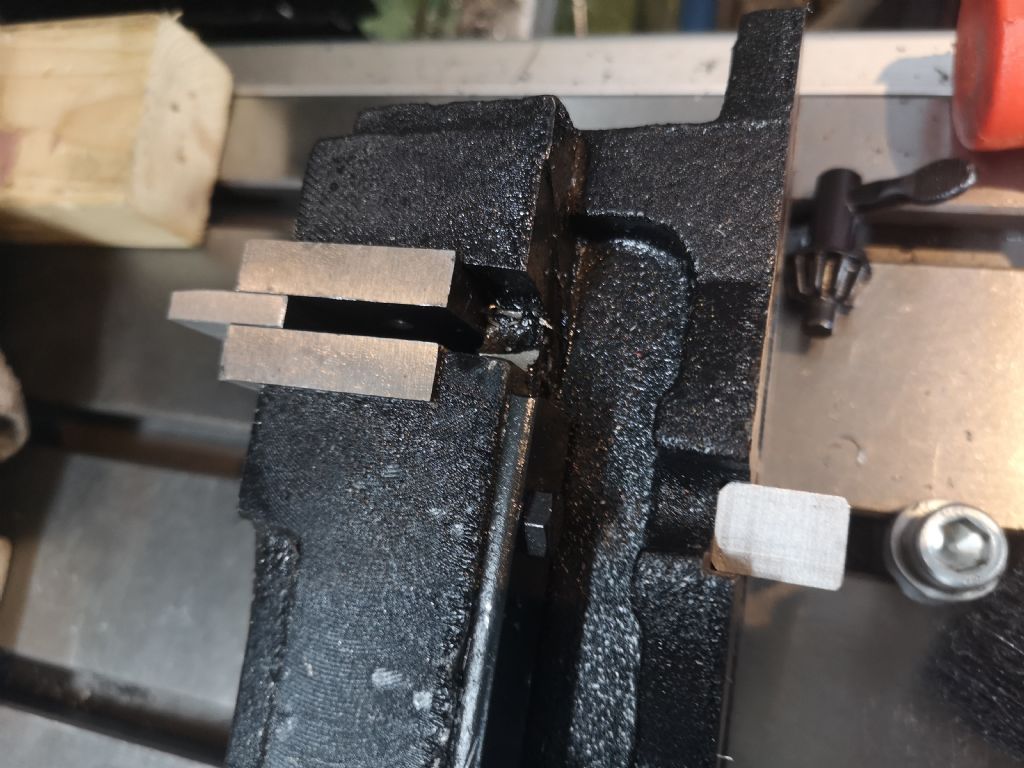

The next step is to clamp a parallel into the vice and turn it over. Taking care to slide the parallel into the t-slot. Biasing it to line-up with the front of the fixed jaw. Once home, the plan was to clamp the vice down mill out any discrepancy:

However, there is a problem. The jaws aren't parallel to each other:

So for now, I've strapped it down biasing on the fixed jaw:

This is it's the position she currently lay.

I figured it best to wait for feedback before taking the next step, in case there was something fundamental I was missing.

Lee Jones 6.