Posted by Martin Connelly on 22/05/2020 18:58:38:

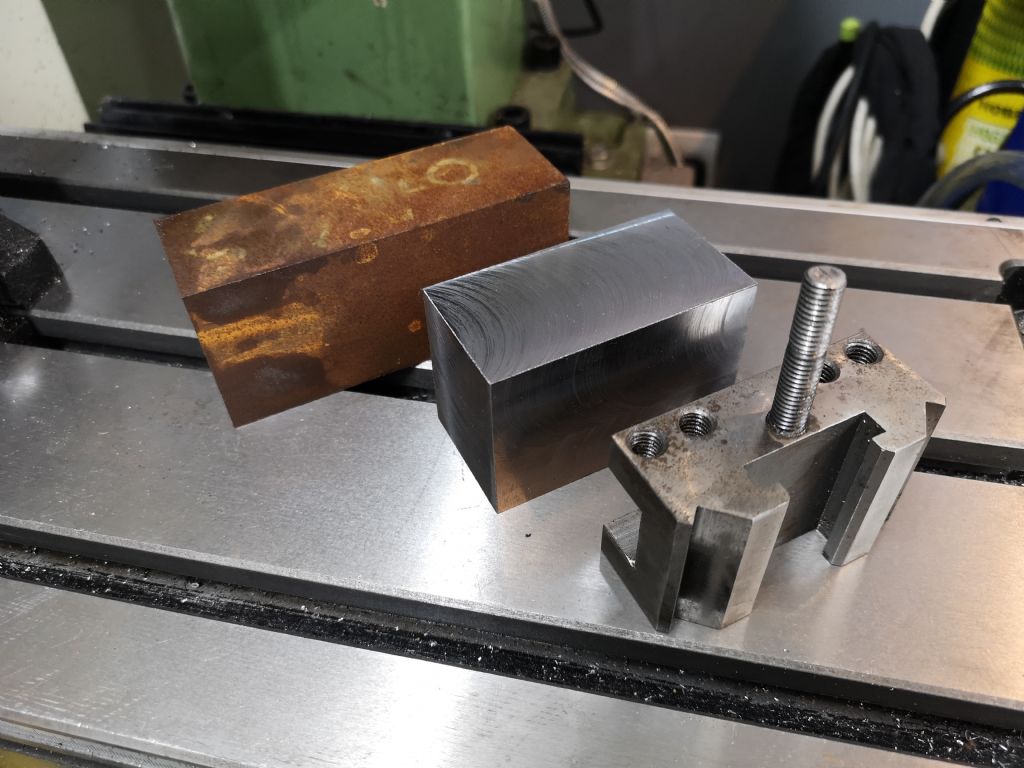

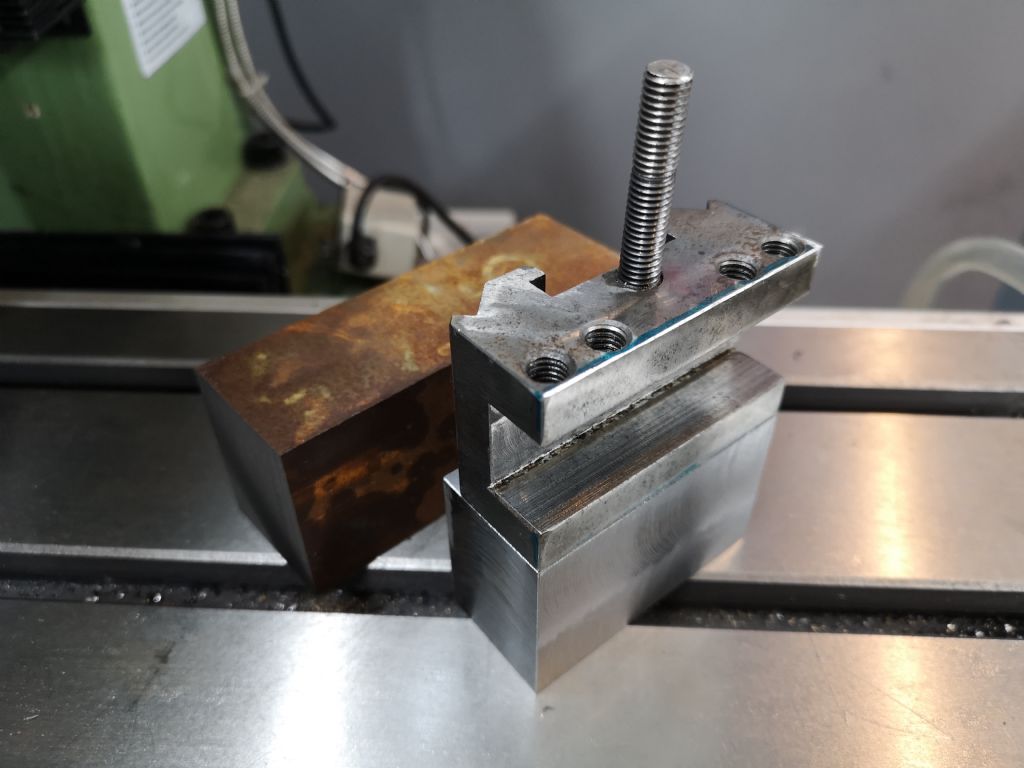

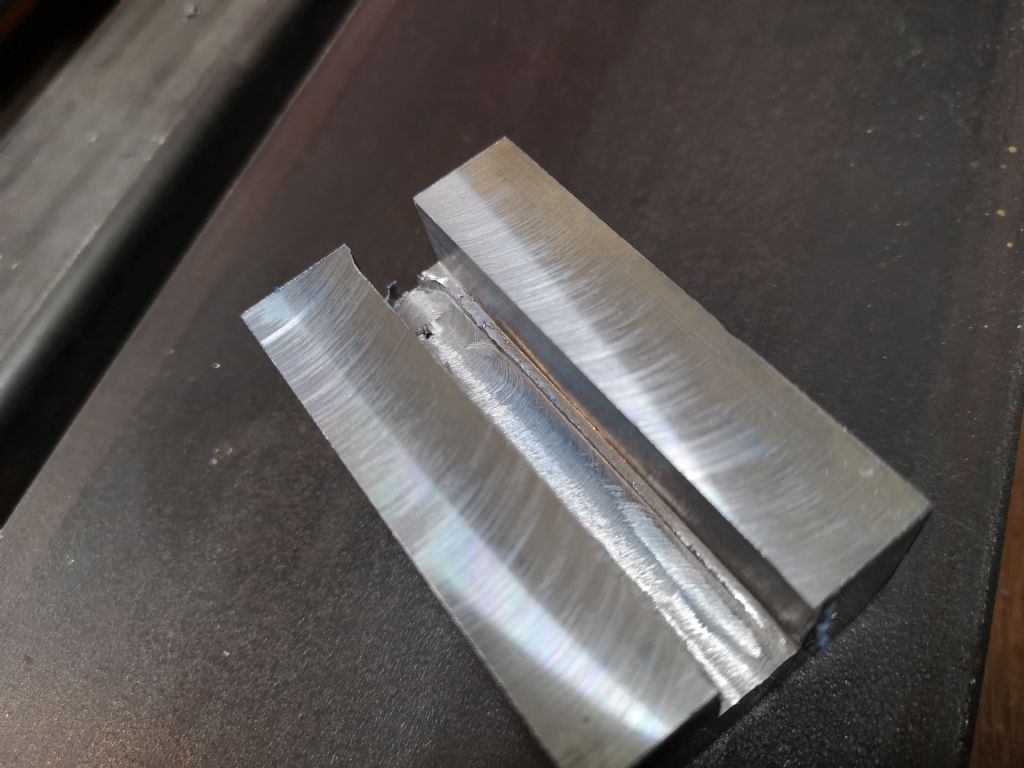

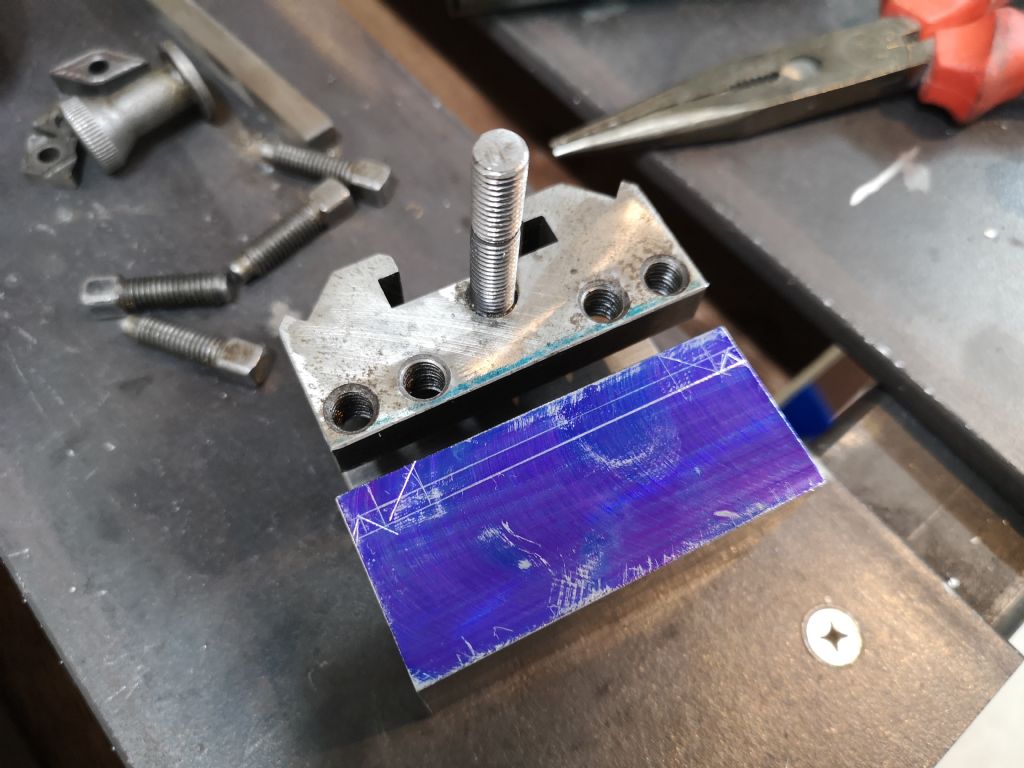

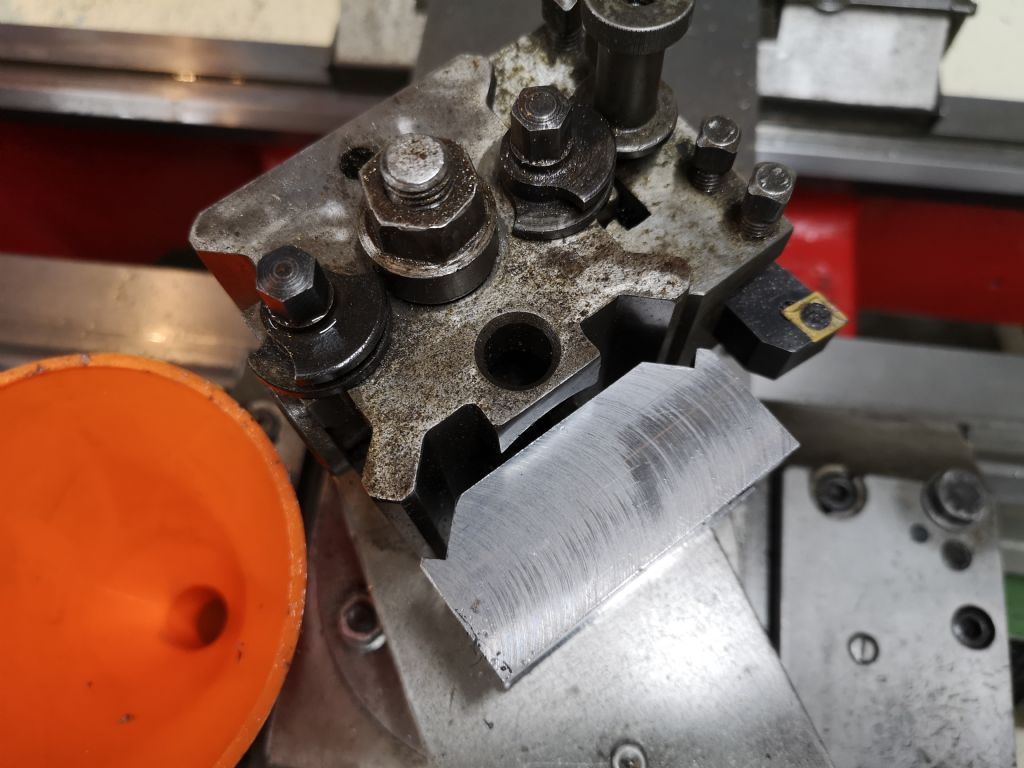

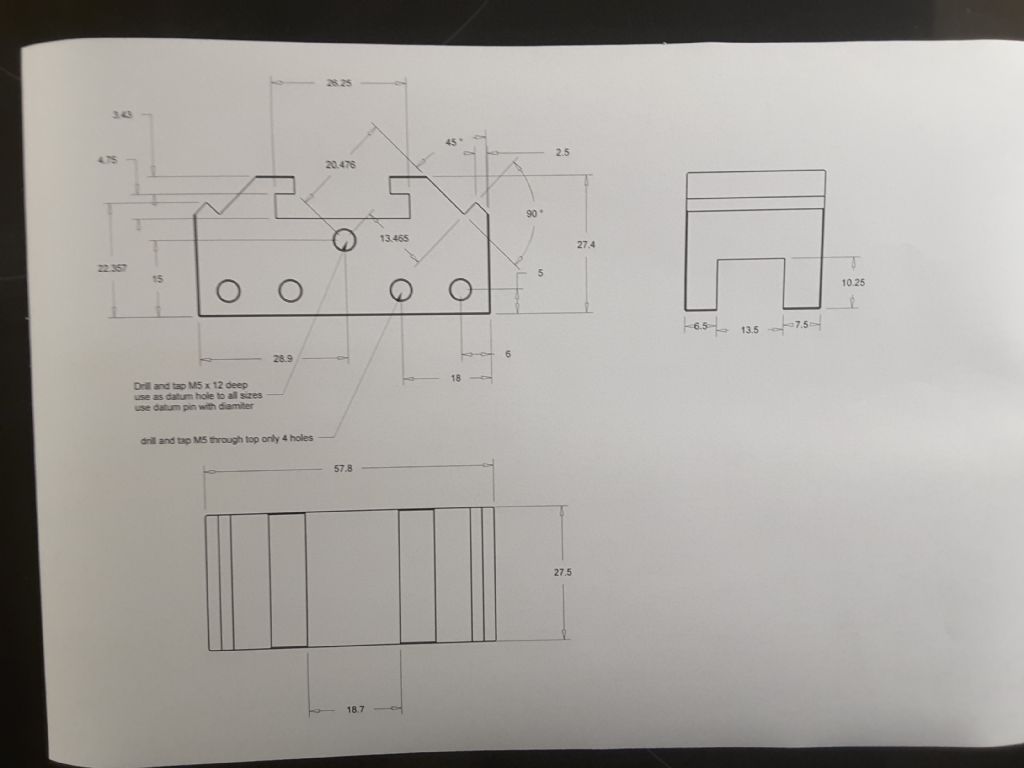

Lee, did you see this by John Baron on the Cutting a 45 degree V thread page 1? There was also a suggestion somewhere to cut a narrow slot first then cut the vee. This is how some of the purchased ones I have had their vees cut (the slot that is, not the 45 degree cutter part).

Martin C

Hi Lee, Guys,

Whilst your picture shows one way of getting a 45 degree angle, its not a good way of holding work for milling. My recommendation would be to buy a proper inverted cutter and secure the work to the mill table properly. At a pinch you could use a 45 degree HSS or carbide countersink and take it easy with the cut.

I did see both of those posts, thank you.

Not overly keen on using a countersink for this.

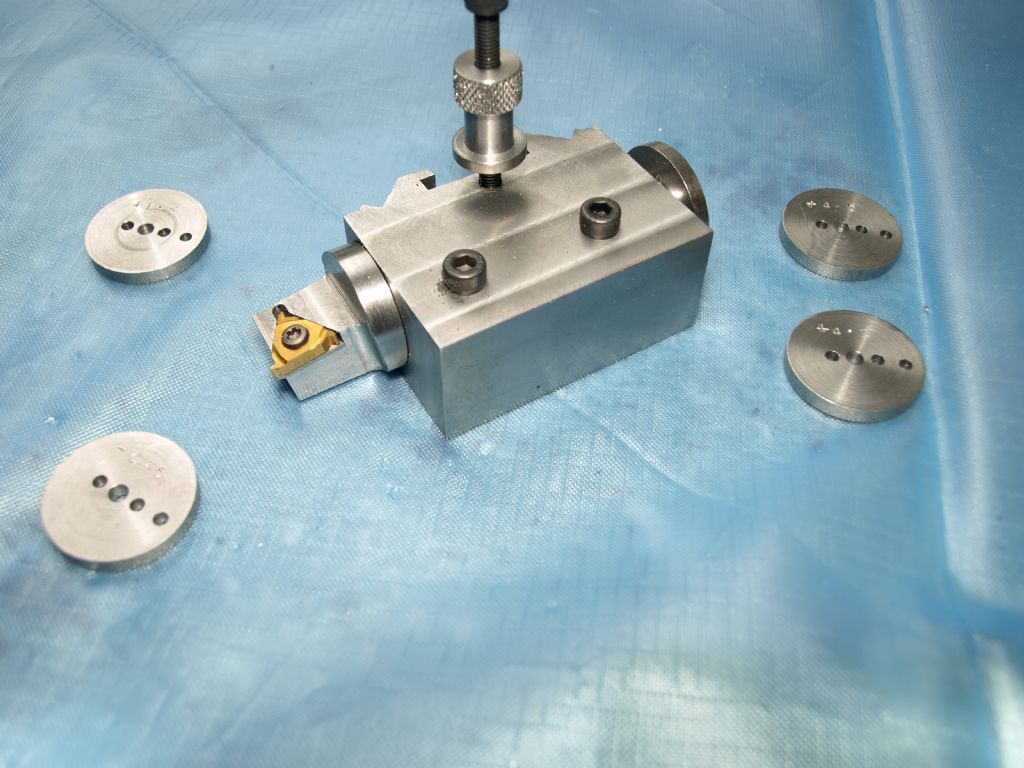

Seen some 45 degree side cutters and was considering something like THIS.

I think I'm going to go for a sine plate, 'cos why not (and I think I'll get use out of it beyond this project).

Lee Jones 6.