All, as part of my Princess Royal steam engine build, I want to make some brass oilers. I’m wanting to make four for the crosshead bars, two for the main bearings, and no doubt others for other areas. Most will need to be identical pairs or sets of four.

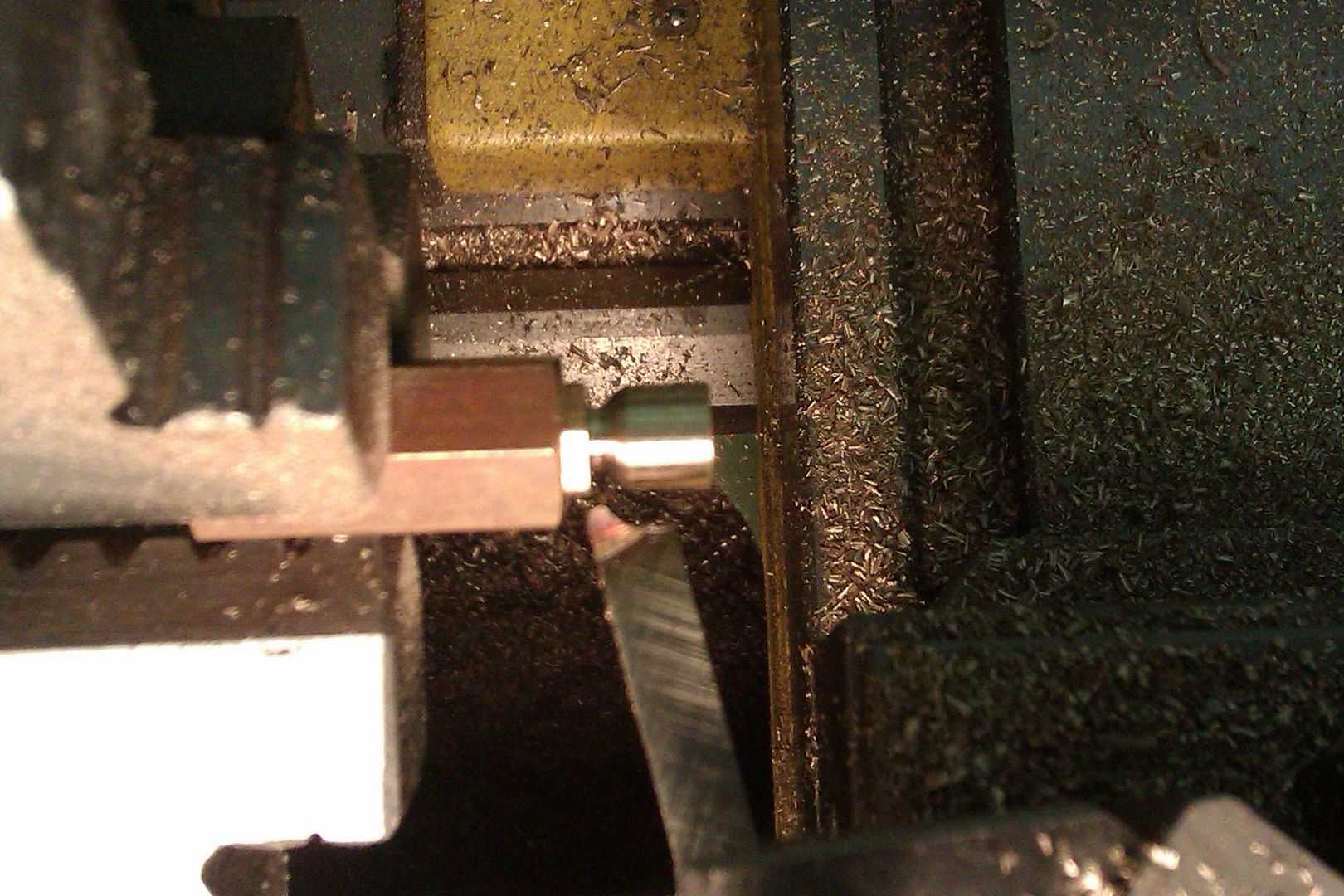

I played around with profiles yesterday (not really considering how to make identical ones). I can design them so that I have co-ordinates from CAD, then swap stock in and out of the lathe until each pair or set is done. Left is one I made, right is a larger Stuart models version:

It’s easy enough to profile and drill the main body, but then after parting off, holding a stepped profile to thread the opposite end is tricky.

I’m thinking the way to go is to thread the end first, along with as much of the profiling as I can, then perhaps part-off the partly finished item and mount into a tapped bit of material in the chuck. Then do the cleaning-up and drilling of the part from there. Slightly concerned that the thread may be too loose to get the part concentric for drilling what would end up being a fairly thin-walled component.

Any comments? Thanks.

Dr_GMJN.