I keep the rest horizontal, put the toolbit in the jig and, wrongly touch it up, on the side of the wheel.

NO great forces!

To chip the tip badly, I have to be really brutal.

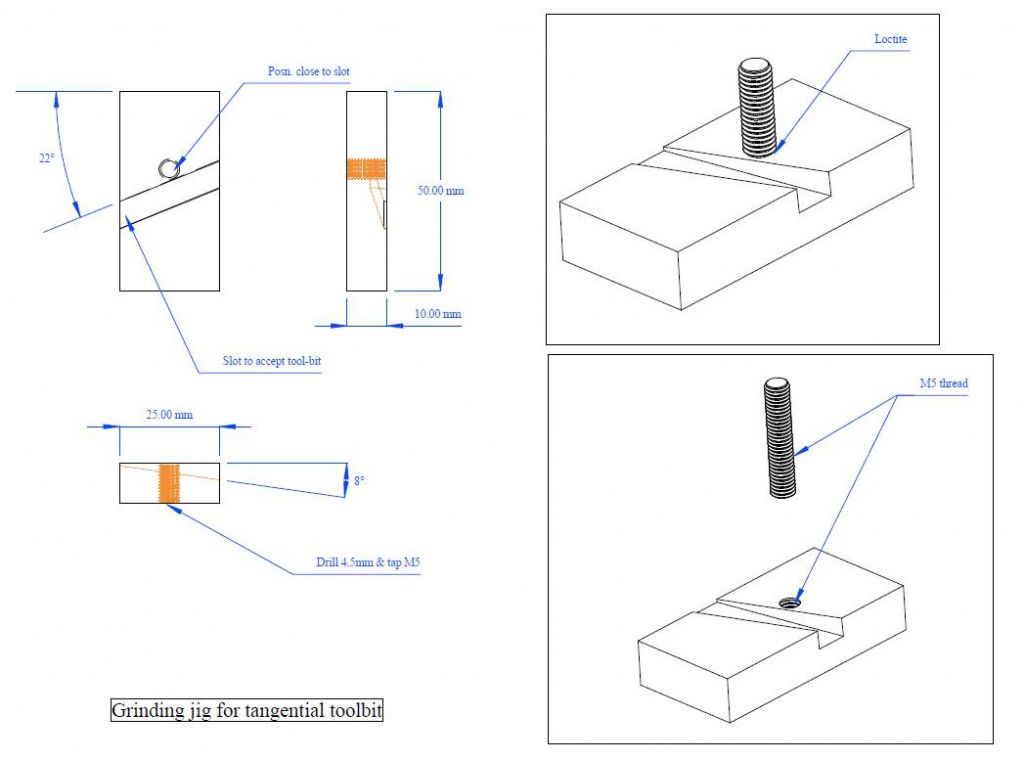

The E E jig sets the toolbit at 33 degrees, (The literature mentions 57 degrees. 90 – 57 = 33 )with the jig sloping at 12 degrees

It has taken about four years of use to wear out the original toolbit, and it tends to see a lot more use than the carbide tipped tool used for roughing; and that does get chipped, especially on interrupted cuts, ( Which can hammer the edge of the Diamond Tool below centre heigh )

Avoid over extending the tool; that will encourage chatter. I cut the back end off the shank on mine, to bring the end of the toolholder hard up against the toolpost. In all machining, rigidity is paramount.

With a freshly ground tool, cuts of 0.0005" (0.012 mm) on steel, are possible, and a fine feed produces a good finish.

I use the Diamond Tool for finishing so avoid taking cuts deeper than 0.025 " a side (0.635 mm) although 0.050" (1.25 mm) is quite possible, maybe even more. Probably, as always, a trade off of DOC /Speed vs tool life l

A Centre Height Gauge is essential to get the best out of any lathe cutting tool. If set too high, the tool rubs overheats and softens (Probably so locally that it is not obvious )

Too low and the clearance angles are wrong which is not good for the process or the tool.

Cutting speeds for HSS should be around 100 fpm (30 mpm ) on non hardened steel.

Being HSS it will not cope well on hardened materials, for those, you do need carbide tips. (Quite entertaining to see red hot ribbons coming off case hardened items! )

Howard GRRRR Smileys

Edited By Howard Lewis on 11/04/2022 17:17:53

Gary Wooding.

Gary Wooding.