Had an interesting time with my Prusa i3 style printer (Factory 3D) today. Trying to print a part that is essentially a 100mm dia cylinder but every time I tried the left hand side would print and the right hand side would be missing or very poor quality. As I am a newby at this lark I quickly decided that it must be down to an unlevel bed. Re-levelled and tried again – same result. After about 3 goes at levelling with the same result I decided it must be something else.

Watching very carefully I noticed that the extruder motor was turning (I have a line drawn on the spindle) when the print head was on the left but not on the right. Just to confirm I went into the move axis mode and could extrude on the left but if I pushed the head over to the right I just got a very faint click from the stepper motor. Checked the plugs which were firmly on and concluded a broken wire which I confirmed with a test meter.

A lot of faffing about later having undone the wiring loom to the print head and replacing the stepper motor cable I tried again. This time no extrusion at all. "Oh bother!" I said and went and had a cup of tea before something terminal happened to the printer.

It turns out that standard stepper motor cables are all different, a bit of swapping the terminals in the Dupont connector around and all was eventually working again. Having spent most of the day being in turn confused, annoyed, frustrated and annoyed again I was wondering:-

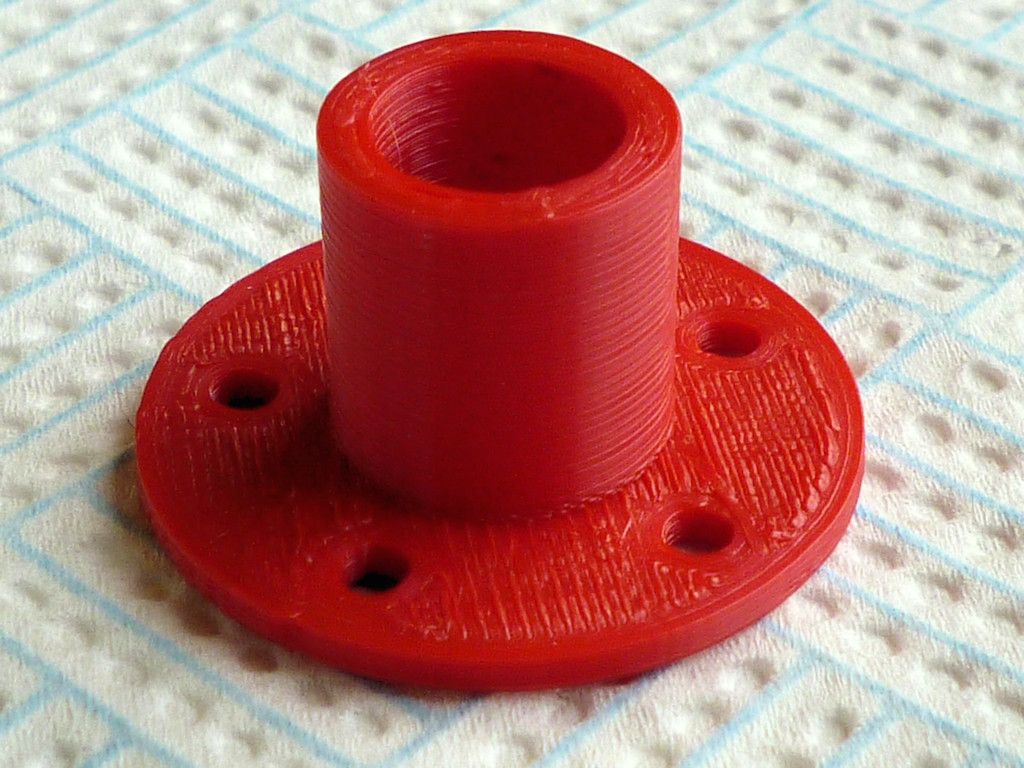

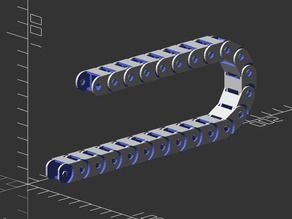

Is there a better way of cabling up the moving bits in particular the print head which needs to up and down and left and right. At present I have all the witres in a braided nylon sheath with spiral wrap to give it some stiffness. The wire broke somewhere near the termination point on the head but to me it doesn't seem to bend much at that location. I was thinking of using a cable chain or is there something else that can be done to prevent future breakages?

John

Martin Kyte.