Posted by Michael Gilligan on 06/08/2023 02:43:15:

Posted by S K on 05/08/2023 23:19:52:

[…]

if true, it seems that there's a lot of payoff to building a better opto system, especially if you are interested in short-term effects.

… spot-on [

… spot-on [

It's the "if true" question that's captured my interest & why I'm developing an experimental pendulum.

A good way of solving problems is to copy previous work, doing better by implementing best practice in new ways. Knowing how much weight a bolt needs to support, choose a standard size and type. Don't design a new fastener or anything else unless essential. Avoid Experiment.

I'm taking an experimental approach. If I only wanted to build the best possible clock, it wouldn't have a pendulum!

My interest is in seeing how good a pendulum clock I can make with modern methods, a hobby. So far measured two prototypes & measuring is difficult in itself. The second prototype tackled flaws revealed by measurement.

An important principle is that I fix big problems first:

- Basic mechanical issues, mainly in my over-simple poorly-made suspension

- Changing temperature causes major errors that must be managed

- A surprise, changing humidity caused significant errors in a carbon-fibre rod used experimentally as a combination rod and suspension spring. I believe humidity alters the rod's flexibility rather than its dimensions.

- air-pressure causes small deviations, and has to be managed too

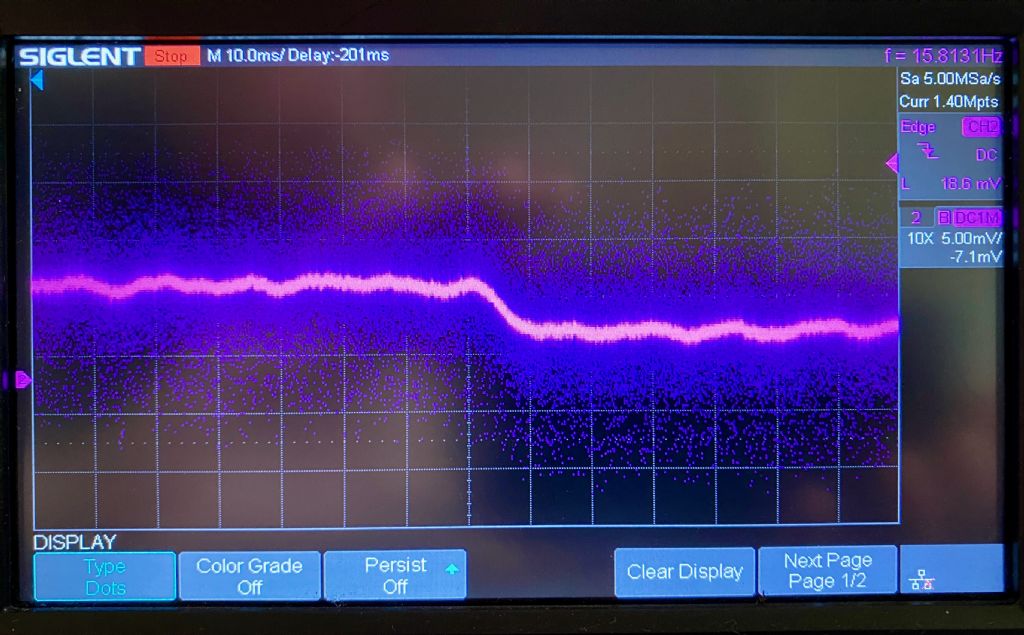

All that done, I still have detectable errors. In particular my pendulum is 'noisy', that is its period varies slightly beat by beat. In a mechanical clock, the escapement and impulse are likely suspects. My escapement is an Infrared beam. and the impulse is applied by an electromagnet.

Focussing on the electromagnet, it's clear from my measurements that over powerful impulsing always disturbs period. More, is it best to apply the smallest possible impulse on every beat, or to minimise shock by applying a larger impulse every 'n' beats, and letting the pendulum swing free as much as possible? My results are contradictory: first prototype was best impulsed every beat, but the second works best impulsed every 'n' beats. Don't know why.

Moving on, I believe most of the noise in my pendulum is due to a mistake! The sensor holder is too short & the IR detector isn't triggered until the bob is a few degrees past dead centre. No excuses, George Airy proved about 1830 that the impulse must be applied at dead centre, but experimented with a gentle magnetic pull at top. Having decided George was right, I messed up the 3D-CAD model so the real clock is wrong.

Next step is to rebuild the clock, hard work because I shall add the vacuum plumbing too. Delayed due to illness.

However, at this stage, I've no evidence that the IR beam in my clock is causing any trouble. As the beam uses ordinary components, wouldn't be surprised to find noise due to mismeasuring, but so far not detectable. Why not? I posit any beam outperforms a mechanical escapement simply because no force is applied to the pendulum. Also, beam noise may not matter if the electronics are reasonably consistent. Beam engineering can't be ignored – was necessary to shield the IR receiver to avoid false triggering due to light & reflections.

If the next rebuild shows the beam is causing trouble, that part of the clock will be upgraded. But I've plenty else to worry about before needing to spend time and money on it. And I want to measure just how good or bad a basic IR beam is before moving on.

FGPA and similar suggestions aren't attractive yet. At present, applying FGPA to my clock would be a lot of effort for not much return. I have to find and fix big errors first. I'll die happy if my clock performs so well that FGPA is needed to improve it.

Quick explanation of FGPA! A digital computer can emulate any logic function by applying a sequence of instructions to data. Very flexible because the instructions can be changed at any time. Not all rosy though. Though fast, the electronics in a computer have to do a lot of time consuming work – read next instruction, decode & execute. Therefore plain electronics are faster than a computer programmed to do the same job.

Unfortunately hard wired electronics only do one job and are expensive to design, build, and debug. Change very difficult.

A Field Gate Programmable Array is a good alternative: a gigantic chip stuffed full of logic circuit blocks that can be interconnected in any way. Connections between blocks are programmed, perhaps by blowing fuses to disconnect unwanted circuits, producing a configuration that does a single complex function at high speed.

Blank FGPA are mass-produced and applying them to a problem is more like computer programming than assembling conventional components. Very common now for electronics to be built from a mix of microcontrollers, FGPA, &specialised chips. The combination is fast, affordable, and mostly programmable. A few clever folk understand it all, but development is mostly done by specialist teams. I'm probably too old to tackle FGPA now, but it's good stuff.

Dave

John Haine.