Posted by Ketan Swali on 11/05/2020 15:51:44:

Posted by RMA on 11/05/2020 13:56:59:

Real feeling of nostalgia here reading this post. Sadly Timken (British Timken) no longer exists as they transferred operations from the UK to India and the two factories I spent my apprenticeship at are now housing estates!

I spent a while as a technical rep for the company before moving on to new pastures and I would advise anyone who has doubts about fitting bearings on a machine tool to ask the bearing company for advice. No point in trying to re-invent the wheel as it's old technology and all the info is readily available.

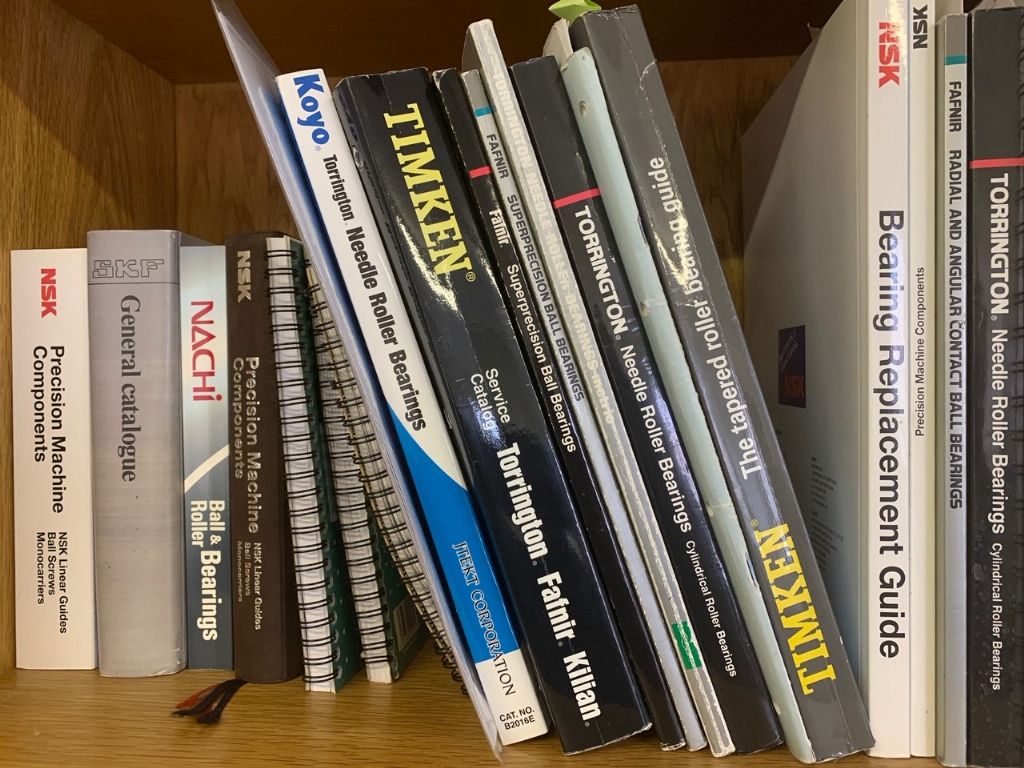

I have a good collection of bearing catalogues accumulated over the years. Initially, trading in bearings was our main business. Here is a photo of a small section of the book shelf just above where I sit in the office:

It represents a snap-shot of how Timken went through transformation of ownership over time …. TIMKEN.. followed by being part of Torrington, .. followed by separation into Koyo – JTEKT taking over Torrington… and so on. These buy-out and changes have always been there, and very common in the bearing industry.

I was once told by the Torrington rep., that the likes of TIMKEN/Torrington were mainly here/ there to primarily serve the automotive production industry. When I entered the bearing sales industry back in the late 1980s, Mr. Timken was busy trying to shut down Chinese factories which were making equivalent type of bearings. Ten odd years later, Timkens own production to serve Asian markets is based there, along with other locations throughout Asia. By the time we stopped getting direct supply from TIMKEN when it was part of Torrington in mid 2000s, the European market for Tapper Roller Bearings was served by their production facilities in Turkey. By this time, it was difficult to consider/justify paying the prices they wanted for the brand for 'standard' TRB sizes, when we could get Japanese equivalents in NACHI and KOYO – without compromise on quality – for nearly half the cost which TIMKEN – made in Turkey wanted.

From what I can see from this link, currently TIMKEN still remains an AMERICAN brand, with FAFNIR being part of it. Operations – as in decision making – still remain firmly in Ohio USA, with Madras – Chennai link just being another part of their global empire to serve their customer base, wherever they may be.

Ketan at ARC.

Edited By Ketan Swali on 11/05/2020 15:52:16

Thanks for the update since the '80's. I lost track of the company, and a few colleagues when they shut down in England. I know a fellow apprentice who ended up being the works engineer and went to India to set up the factory there, and then was no longer needed!

When I started in the '60's, production at Northampton was mainly for automotive and machine tools. Business boomed when the Vietnam war was on, a whole production facility for fighting vehicles, and we had many car plants around the country then. Larger bearings and railway axle boxes were produced at the Daventry factory. Large bearings used on radar installations and larger machine tools, even the BT tower in London. As a rep, I visited many customers making cars; trucks; planes; machine tools and ships, in fact anything that required bearings. What industry we had then!

It was a great place to work, they relocated from Birmingham during the war into a brand new factory which at the time was the largest factory in Europe. The only reminders now are a couple of road names on the new housing estates…..how times change!

Edited By RMA on 11/05/2020 18:00:36

Ketan Swali.