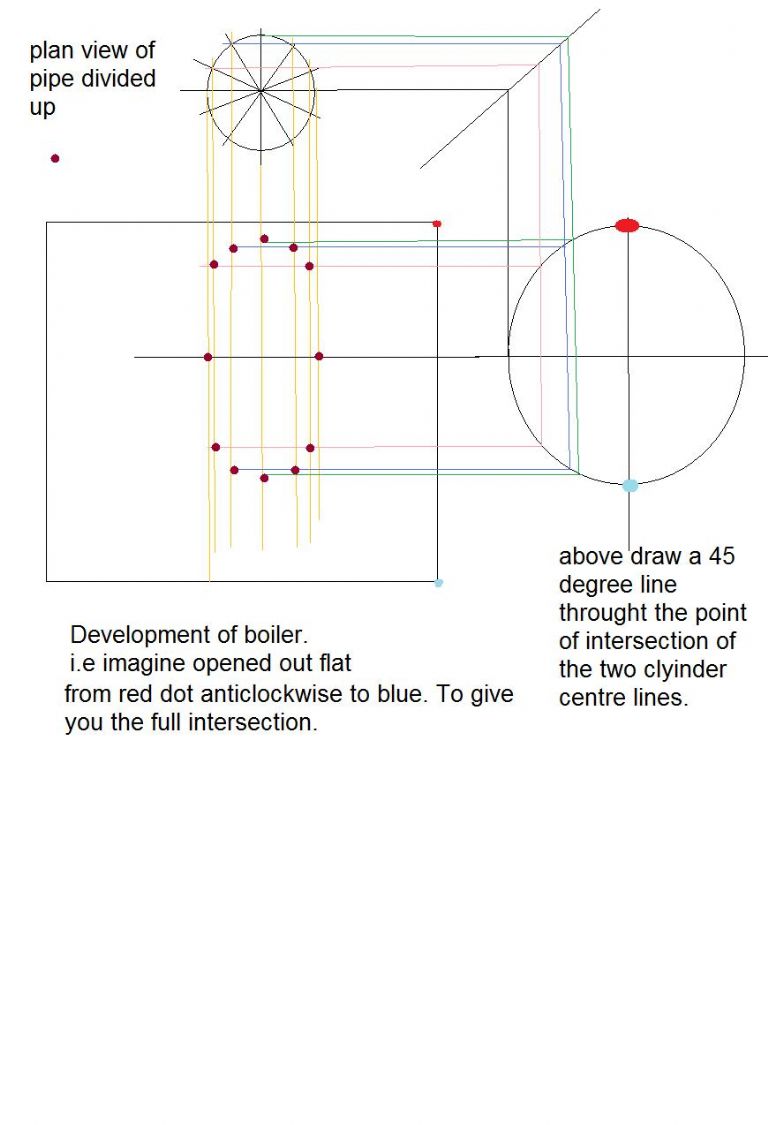

Clive, what your projection produces is the view of what the tube would look like while it is round. If you want to develop the shape of the tube as it would be if flattened out you have to do more work. You could draw radial division in the circle on the right, then project them across your developed shape. The radial lines would be getting closer together there as you get further from the centre. You then draw a similar grid of lines, but with the horizontal lines at a constant spacing, equal to the circumferential distance between each radial line. Transfer the sizes from the original set to the new set, and it will stretch the shape at the ends by the right amount.

However, unless the plan is to cut the hole and then roll the tube shape, which I would not advise, that approach should not be needed. The problem is not to find what shape the hole would be if the tube were flattened, it is to make a hole which is reasonably close to round in the actual tube

The other thing is your smaller tube seems to be meeting the larger tube at a tangent. The original problem was for a dome bush, which would mean that the centre lines of the two tubes (extended) would meet. I did a tube like yours once for a model water tube boiler, of a simple Babcock and Wilcox type. Simple because it only had one bank of tubes, which used a cross tube across the drum for a header. I made the semi elliptical cutout by just filing until I had a good fit…

regards

John

Clive Farrar.