Hi Guys

I am very hopeful somebody out there can offer me some advice regarding my power feed. The feed is on my Bridgeport mill. The mill is 3 phase and I run it through a Jaguar Inverter. The power feed side runs on 110V I power the mill through the inverter and everything still works fine Spindle etc.

I was using the power feed on a job taking medium cuts and all was fine with no issues. I then went to proceed with another cut and nothing ! I wasn't using the power feed to the Y axis but this also now has no power.

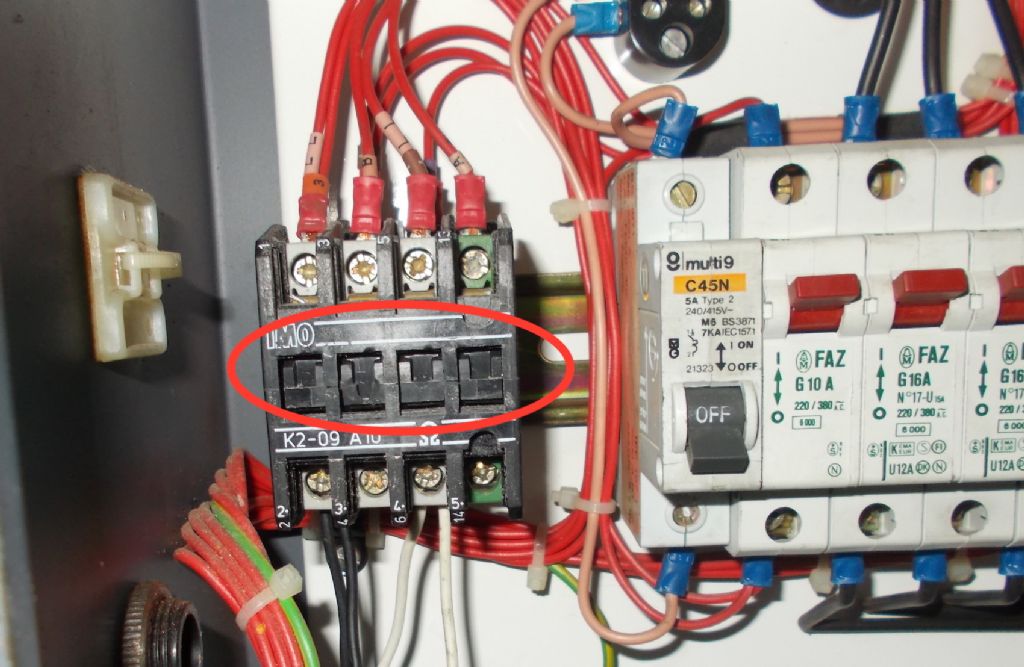

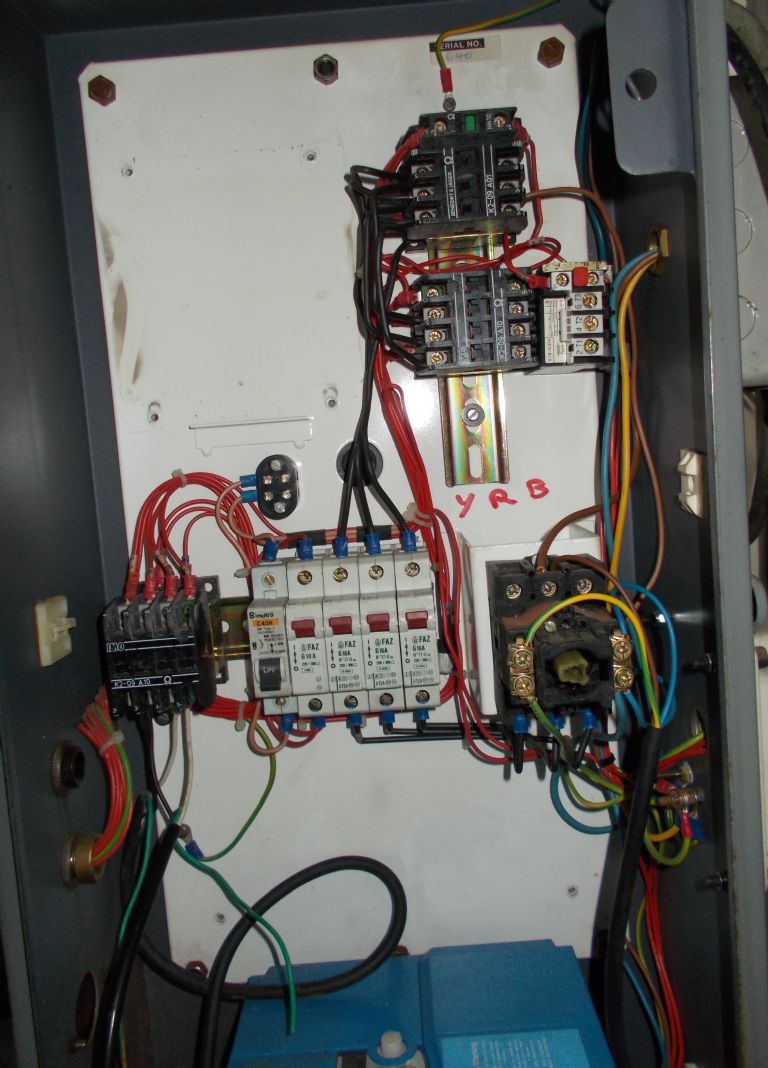

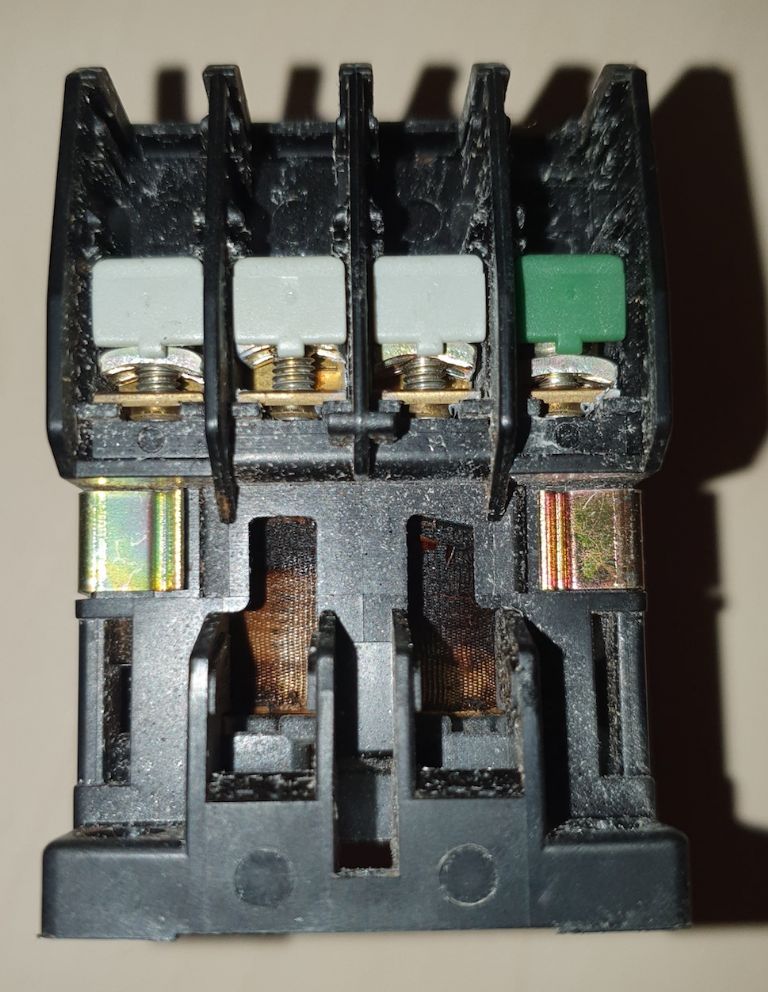

Opening the Mains power box shows the ( MCB ) ? has tripped. I can reset this and it remains set but still no power. Looking at the contactor to the left hand side it appears seized . The other contractors allow movement of the part circled in the photo ie spring back when pushed ( Not whilst plugged in I may add ) I don't mess in there under power. I can also see and hear the other contactor move when the on switch of the mill is pressed. The power feed contactor does nothing and as I say appears solid. Is it likely that the contactor is the problem or am I just being very hopeful.

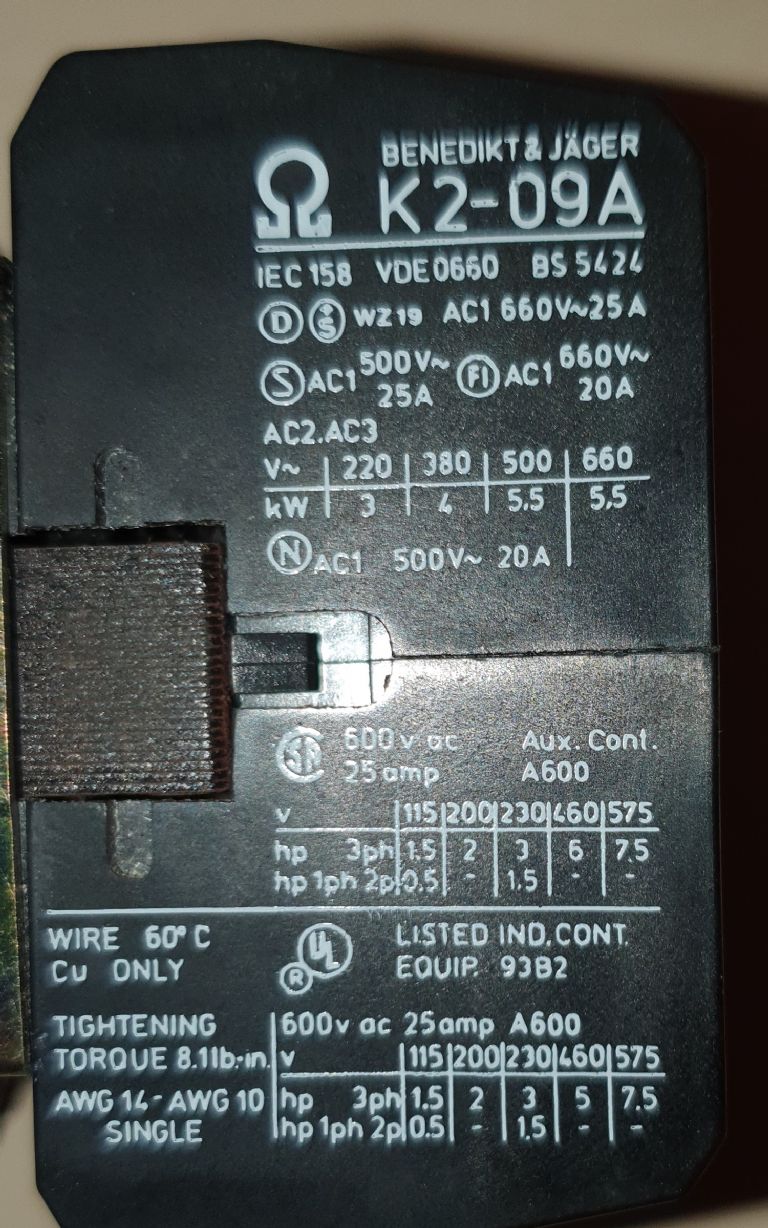

I have found the same contactor on line or at least one looking identical with the same code K2-A9 A10. Am I to assume if this if required it will be the same voltage etc. Or will there be variants of this. I am NO electrician.

There are no in line fuses that I can see. I have an old identical power feed which was removed as it has a damaged gear inside but still worked under power. This has no power either and so I am assuming it isn't a power feed unit fault, Also both axis now no longer work.

Very long winded I know but any help or advice would be very much appreciated.

Edited By Dave C on 10/10/2021 20:10:32

Edited By Dave C on 10/10/2021 20:11:12

Edited By Dave C on 10/10/2021 20:12:19

Mike Poole.

Mike Poole.