Portable Engine Model Engineer Article by Tony Webster

Portable Engine Model Engineer Article by Tony Webster

Home › Forums › Model Engineer. › Portable Engine Model Engineer Article by Tony Webster

- This topic has 91 replies, 15 voices, and was last updated 7 June 2012 at 18:58 by

Keith.

-

AuthorPosts

-

11 May 2012 at 18:59 #90626

David Clark 13

Participant@davidclark13The valve chest is shown with a cavity 3/4 inch wide yet the drawing of the valve has the 13/16inch dimension fitting into this 3/4 inch space.

When the valve is assembled with the nut this will increase the whole assembly by another 1/32 inch giving an overall width of 27/32 inch which is an even more impossible fit into the ¾ inch space.The valve chest has the valve rod sliding directly in it with no gland. Surely this is incorrect?

Is it correct that the cylinder does not sit centrally on the curved flange front to back, or should the 3/4 inch dimension for the position of the 1/4 inch hole be 15/32 inch to allow for the 1/32 inch projection of the cover faces beyond the cylinder.

regards David

Edited By David Clark 1 on 11/05/2012 19:12:03

11 May 2012 at 19:38 #90628David Clark 13

Participant@davidclark13Hi Jason

On page 2, you have transposed the 3/8 and 5/16 dimensions.

5/16 + 5/16 for the slide bars + 5/16 for the slot = 15/16 which is correct.

If you make the right hand diameter 1 inch when it is cut away to take the slidebars it will probably be about 15/16 at the edges.

The centres of the slide bars should be 11/16 inch, not 13/16 as drawn. (The screw centres are still 11/16 and 13/16 respectivley.

regards David

Edited By David Clark 1 on 11/05/2012 19:38:24

11 May 2012 at 19:50 #90629David Clark 13

Participant@davidclark13Hi There

Most of these dimensions are easy enough to figure out but I have spent a lifetime in engineering. This is what sets us apart from the 'Armatures', experience and common sense.

regards David

11 May 2012 at 21:05 #90634 JasonBModerator@jasonb

JasonBModerator@jasonbHi David and indirectly Tony.

I have looked through the above and list below my comments. I have tried to make it a bit easier to follow by starting each paragraph with J or T so we all know who is saying what. I have only listed things that are still awaiting answers or that I do not agree with. David if you could forward this to Tony It would be much appreciated.

T.The overall width of the firebox is 4 3/8 inch. The inside width of the horn plates is 4 3/8. Clearly there is no room for the head of the corner stays.

J.How do you get this figure? If boiler barrel is 4.0” and there is a 3/32” wrapper that makes a total width of 4 3/16” (4+3/32+3/32)

J only other thing I can see a possible clash with is the cylinder saddle will foul on the large bush on the firebox crown but will await the final drawings

JQ. Should there be blind bushes to mount the firedoor Hinge

TA……..

JQ. There is no depth for the steam port slots.

T.A They must not break into the cylinder bore.

J Or the exhaust passage drilling which is nearer the surface

JQ. Crosshead has no thickness given.

TA. 3/8 inch should be fine.

J. NO this will not fit the bar spacing it should be 5/16 to match the flat on the end of the cylinder cover as described on page 502

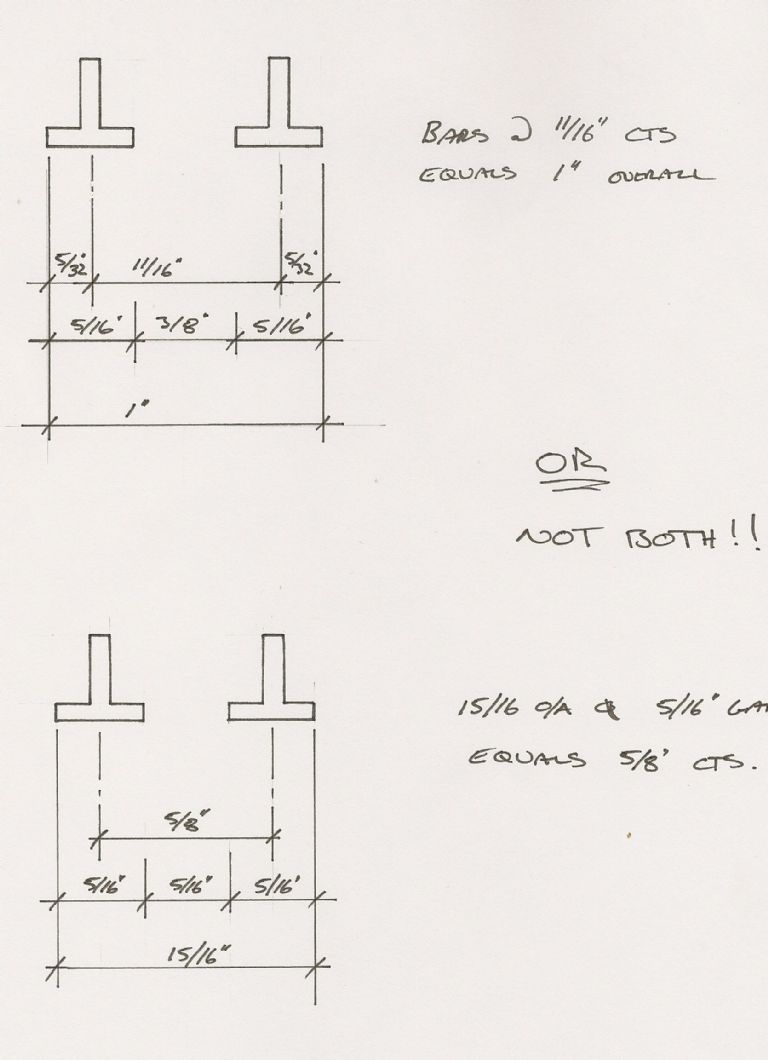

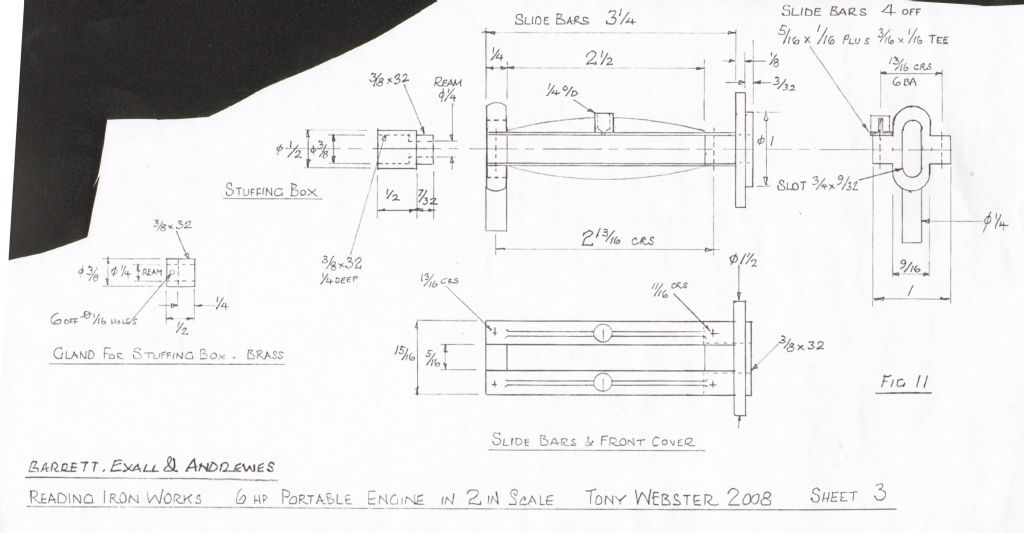

Slide bar drawing

J Basically my hand drawn one is correct so David you may use this if you want in the mag but see last few items at teh bottom

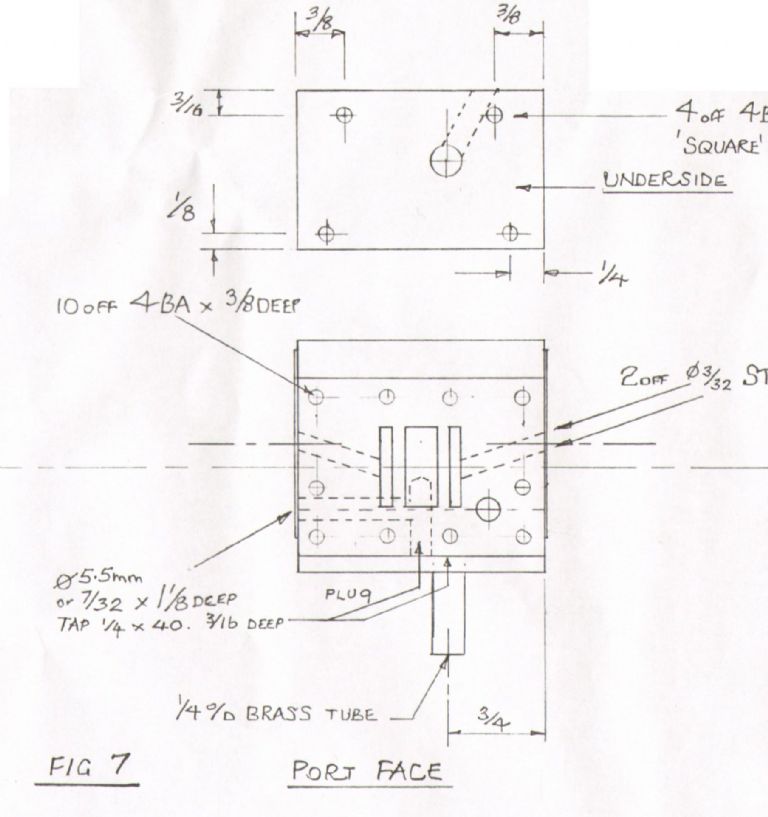

The valve chest

J.The blind valve end is shown with a 3/16 x 40 male thread, if you look back at issue 4427 the valve chest that this is meant to screw into is shown with a plain 3/16 inch hole at each end. That is why I said that I hope no one has made the chest as it should obviously have had one end threaded 3/16×40 for the bush to screw into.

J.While correcting the valve chest it’s worth pointing out that there is no form of gland shown on the rod side either so may be worth sorting that out at the same time.

T.A……..

Cylinder saddle.

J.Q. Is this the actual view of a developed shape of the curved part.

J.Q. The 1/8in. dimension at the bottom left is wrong, it should probably be ¼ inch.

J.Q. The two 9/32 inch dimensions on the left seem wrong as the hole will break through the edge, 11/32 inch would be nearer what is right.

J. I feel this drawing is wrong, the reason being that the position of the 1/4 inch steam feed hole and two of the four mounting holes are dimensioned at 3/4 inch and 3/8 inch in from the edge respectively. They also have the same dimension in from the end of the inverted cylinder plan that was in issue 4426. The problem is that the base of the cylinder is only 1 15/16 inch long but the saddle is 2 inches long so no allowance has been made for the 1/32 inch difference at this end but it has at the other because the holes are shown at 9/32 inch which is the 1/4 inch + 1/32 inch. See also my drawing in a previous post and wrong items in red

TA…..

J.The valve chest is shown with a cavity 3/4 inch wide yet the drawing of the valve has the 13/16inch dimension fitting into this 3/4 inch space.

When the valve is assembled with the nut this will increase the whole assembly by another 1/32 inch giving an overall width of 27/32 inch which is an even more impossible fit into the ¾ inch space.J.The valve chest has the valve rod sliding directly in it with no gland. Surely this is incorrect?

T.A…..

T.On page 2, you have transposed the 3/8 and 5/16 dimensions.

T.5/16 + 5/16 for the slide bars + 5/16 for the slot = 15/16 which is correct.

J. No the 5/16 is mentioned in the text as the size to machine the flat on the cylinder cover, this sets the vertical gap at 5/16” you yourself said you went out to the shed and measured the width as 3/8

T.The centres of the slide bars should be 11/16 inch, not 13/16 as drawn. (The screw centres are still 11/16 and 13/16 respectivley.

J. This just contradicts what you said above if the bars are spaced on 11/16” cts then the overall width will be 1” not 15/16” (11/16 + twice half of 5/16 = 16/16 )

T.If you make the right hand diameter 1 inch when it is cut away to take the slidebars it will probably be about 15/16 at the edges.

J. Outer edge of slide bars should be 1” as two reasons above so to give the bars full support the spigot on the end of the cylinder cover should be 1.048” as shown on my version of the drawing

Have a good evening, Jason

Edited By JasonB on 11/05/2012 21:06:10

11 May 2012 at 22:28 #90644Martin Cottrell

Participant@martincottrell21329Posted by David Clark 1 on 11/05/2012 19:50:37:Hi There

Most of these dimensions are easy enough to figure out but I have spent a lifetime in engineering. This is what sets us apart from the 'Armatures', experience and common sense.

regards David

David,

Speaking as an amateur in terms of my own engineering experience, I don't think experience and common sense should be seen as a prerequisite to overcoming someone elses shoddy workmanship. Whether amateur or professional, you need a set of accurate and well annotated drawings to convert 2 dimensional pictures into 3 dimensional stuff that hopefully fits together, works and looks like what the originator intended.

I accept that errors will occasionally creep in for various reasons. However in this instance the number and range of errors and omissions highlighted by Jason in just a few magazine issues is frankly well beyond acceptable especially in a magazine that aspires to promote model engineering excellence.

I'm sure there are a great many model engineers who have no formal engineering education or experience who look to this magazine and others like it for inspiration and guidance. I personally have always held engineering and engineers in high esteem. If this fiasco is representative of British engineering then I shudder to think how something as complex as Concorde ever took to the skies, always assuming it wasn't actually designed as a submarine and something went wrong between the drawing office and the machine shops!

Regards, Martin.

12 May 2012 at 06:36 #90648Springbok

Participant@springbokMartin,

I think your comments about Concorde has upset everyone in the Patchway/Filton and surrounding Bristol area and I was involved at the time with the drawing office and this project. Around 1950 my father taught me the rudiments of how to use a Myford ML7.

Now task in hand

David is the Editor and cannot build every item that arrives on his desk. Yes I am sure there are articles that come in where the drawings have a multitude of errors. Try the Rob Roy ones for starters.

I built a 7.25g Loco from a series in ME and the author assured me that as he was useing CAD and every drawing was spot on. Have a look at the "Anna" forum. Some chaps gave up after spending a lot of dosh..

Is everyone who is inputting into this thread actually building this project it would be an interesting survey.David

I think I have worked out why text is going under adverts it is so simple it is silly will PM you

Bob

12 May 2012 at 13:40 #90672Martin Cottrell

Participant@martincottrell21329Hi Bob

Sorry, it wasn't my intention to upset the good people of Filton especially since I have to work there occasionally! I was hoping the exclamation mark punctuating the end of my offending sentence would have indicated its tounge-in-cheek nature, perhaps I should have included a nice big smiley

.

.On the subject of Concorde, I well remember being in Bristol the day she came back home for the very last time. I was up on the downs by the suspension Bridge and it seemed Bristol in its entirity had turned out to welcome her back. An amazing and emotionally charged day, one I shall never forget. Its sad to see her ending her days parked up all alone in the far corner of Filton airfield.

Anyway, back to the subject of this thread, I appreciate that David can't build every model to prove the design and drawings but surely they should be proof checked prior to publication to weed out all or most of the errors that Jason has pointed out in his extensive postings? Whilst professional engineers may well be used to dealing with poor drawings, surely a construction series aimed at beginners should be backed up with accurately annotated plans? As an amateur with no formal engineering training I have enough problems dealing with my own shortcomings when I'm making something, surely I shouldn't have to sort someone elses cock-ups aswell before I can confidently start making swarf?

.

.Regards, Martin.

12 May 2012 at 13:50 #90674David Clark 13

Participant@davidclark13Hi There

I do check for errors but usually I am checking that the illustrator has not altered anything by mistake.

We are on a production line, 3 magazines every 4 weeks and no holiday or sick cover if any of the production team take time off.

Also, we usualy check each part of a series. Not the entire series.

We do one part of a series and forget it until the next part is due.

We do not have time to edit an entire series at once.

This is why the valve chest 3/16 thread got missed.

regards David

12 May 2012 at 13:52 #90675David Clark 13

Participant@davidclark13Hi There

Concorde looks like a brilliant design.

When it used to visit the Bournemouth airshow, it used to bank and turn just in front of my house.

It was a superb sight.Unfortunately I don't think I worked on any Concorde parts unless you count the candlestick jacks that supported the wings? during maintainence.

regards David

14 May 2012 at 19:49 #90834David Clark 13

Participant@davidclark13The following will be published in ME 4431.

Some changes will be made if I get the information in time. Comments are welcome. The text is an attempt to get it into order.The drawings for the portable engine have some errors and omissions. After discussion with Tony Webster, we have come up with some clarification and corrections.

The boiler barrel is eight inches long, with 3/8in. cut off at the firebox end for the lower one third of the circumference.

There are five bushes in the boiler, there is one each side of the barrel at the front so there is a spare for a hand pump. The hole sizes for the bushes can be obtained from the bush drawings.

The holes for the eight corner stays for fixing the horns should be 7/32in. dia. i.e. the 1/4in. dia. is reduced slightly in diameter to provide a 'head' to stop them falling through when silver soldering. The head is on the outside which makes it a two operation job. Reduce to 7/32in. dia. part off, chuck the other way round to centre, drill and tap 4BA. (It also cleans the bronze surface for silver soldering.)

The overall width of the firebox is 4 3/16 inch. The inside width of the horn plates is 4 3/8.

The stays go right through the inner and outer firebox side with the inner side holes being 7/32 and the outside being 1/4 with the outside of the stays protruding 3/32 inch from the outer firebox? The stays are stepped to fit into the 7/32 inch holes.

In the end section to the right of the drawing on page 364, the 11/16in. dimension to the first row of stays should be from the top of the foundation ring as shown in the door plate drawing to the left. Also the 1/4in. should be for the foundation ring only and not include the firebox wrapper plate.

The front to back location of the water gauge bush and manifold will be detailed in a further instalment of the series. There is no harm in having a static connection to the water gauge, i.e. a pressure gauge where there is no movement of steam or water through the manifold. I agree that there must not be a connection to the blower or injector etc. from the water gauge. This would have a misleading effect on the water level in the water gauge.

The 1/2in. hexagon for the top water glass connection should not have the 3/16in x 40 tpi hole drilled and tapped yet. Drill 6BA clear and tap the hole in the boiler 6BA. Fix with a 6BA brass screw.

After the boiler has been silver soldered the screw is drilled out and the outer part tapped 3/16 x 40. This is for a banjo pipe connection to the pressure gauge.Boiler: The height of the backhead is 6 inches.

The height of the firebox is 4 1/4 inches, neither is critical.

The wrapper plates are probably overlong and will need trimming to match the flanged plates.The 7/16in. boiler tubes should be 20 swg; a standard thickness that should be available from your friendly model engineer's stockist. The tubes rise towards the front of the boiler.

Before fixing the skirt length (see below) check that the lower tubes will fit the lower holes in the firebox tubeplate, clear of the inside of the barrel.

The important dimension, when setting out the tube positions on the firebox tubeplate, is that the top row of tubes should be 11/32in. from the inside of the flange, (or 15/32in. from the outside of the flange if marking out on the other side of the tubeplate). Do not drill the 7/16in. dia. holes until the flanges have been made.

When the drawing was redrawn for publication the firebox tubeplate thickness of 3/32 inch was not transferred.

The 'skirt' i.e. the firebox inner wrapper should be 5/16 inch below the outer wrapper. The foundation ring should be 1/4 inch square all round but you may be only able to obtain 6mm square which will be fine.The outer door plate (backhead/front plate) and the firebox doorplate should be parallel to each other and vertical.

The firedoor and the water gauge bush should be on the same horizontal centre line and the stays should be equally above and below this centre line and maintain the 11/16in vertical centres. They are offset 1/8in. from the lower ones to place them nearer the centre of the area alongside the firehole.

Get the blowdown bush as low down as you can, i.e. 7/32 inch above the foundation ring.The drawing says two off regulator bushes, one fits the top of the barrel and the other goes on the backhead.

Q. Confirmation of an available thickness for copper in substitution for the 3/32 inch and 1/8 inch thickness shown on drawing. A. Go slightly thicker not thinner.

14 May 2012 at 19:50 #90835David Clark 13

Participant@davidclark13Q. For the cylinder drawing the text says machine the valve face back to lines 1 and 2 but drawing shows it at least 1/32 inch away from them. A. Machine to the line as the text says.

Q. The length of cylinder and protrusion of end faces are not shown on the drawing?

A. They can be found in the text.

Q. There is no depth for the steam port slots.

A. They must not break into the cylinder bore or any of the steam holes.

Q. Width of valve chest given as 3/8 inch?

A. This should be 1 3/8 inches.

Q. Crosshead has no thickness given.

A. 3/8 inch is fine.

Q. No depth for piston ring groove.

A. Make deep enough to take packing or alternatively use O ring charts to fit an O ring.

Q. No length is given for the piston rod.

A. My drawing says approx 2 3/4 long. Check on job before finalising.

Q. No length of 1/4 x 40 thread on piston rod.

A. Make to a length to screw into the crosshead as far as the slot, approximately 5/16 inch. The 1/4in piston rod dia. should be stepped down to 3/16 inch and threaded 3/16 x 40. To save creating a stress point at such a step, taper at 60 degrees inclusive and 'countersink' the piston with a combination centre drill before drilling tapping size for 3/16 x 40.

Q. No depth for cut out in crosshead.

A. 9/16 inch will be OK to clear little end.

Q. The valve chest is shown with a cavity 3/4 inch wide yet the drawing of the valve has the 13/16 inch dimension fitting into this 3/4 inch space.

A. The slide valve should be 13/16 long and 3/4 inch maximum wide to fit in the steam chest. The dimensions have been accidentally reversed.

14 May 2012 at 19:50 #90836David Clark 13

Participant@davidclark13Slide bar drawing

Q. The plan view gives width over the outside of the bars and bracket as 15/16 inch.

A. This is correct.

Q. The plan view gives one end of the bars drilled at 13/16 inch centres and the other end at 11/16 inch centres?

A. This is correct; you will have to relieve the slide bars at the left-hand end, as drawn, to clear the oval section. The view shows the slidebars at 13/16 centres when they should be 11/16 centres. At the 13/16 inch end the bolts are offset outwards from the slidebar centreline.

Q. The end elevation gives the bracket as 1 inch wide and the slide bars project beyond the bracket.

A. The slide bars should not project outside the 1 inch dimension, they are 15/16 inch overall width.

Q. The oil cup does not show the hole carried through the slidebar. A. It goes right through the top slidebar.

The valve chest

The blind valve end is shown with a 3/16 x 40 male thread, if you look back at issue 4427 the valve chest that this is meant to screw into is shown with a plain 3/16 inch hole at each end. One end of the steam chest should be threaded 3/16×40 for the bush to screw into. If you have already made the valve chest, the blind valve end could be tapped 7/32 x 40 and the thread made to suit.

Saddle and cylinder

Q. Is it correct that the cylinder does not sit centrally on the curved flange front to back?

A. The saddle should be made first and the cylinder clamped to it centrally back to front, i.e. 2 inch and 1 15/16 inch dimensions. It is not central the other way, or not until the Valve chest and cover are fitted. The 1 1/4 dim. is to clear the stud holes for the VC otherwise it would be the same as the other side at 1 7/16 centres. Use the saddle to drill the cylinder. If all saddle holes are first drilled tapping size, it will be easy to the saddle as a drilling jig.

After drilling the cylinder, remove the saddle and clamp the saddle to the curved top part of the horn plates. The 1/4 x 40 steam intake hole should line up with the centre of the large bush (other regulator bush) but make sure that the valve face is VERTICAL. The cylinder is not on the centre line of the boiler. It rarely was on portables or traction engines.

14 May 2012 at 19:51 #90837David Clark 13

Participant@davidclark13Hi There

Most of the corrections are above.

Some questions deleted as all will become clear later in the series.

regards David

14 May 2012 at 20:07 #90840 JasonBModerator@jasonb

JasonBModerator@jasonbQ. The plan view gives width over the outside of the bars and bracket as 15/16 inch.

A. This is correct.

Q. The plan view gives one end of the bars drilled at 13/16 inch centres and the other end at 11/16 inch centres?

A. This is correct; you will have to relieve the slide bars at the left-hand end, as drawn, to clear the oval section. The view shows the slidebars at 13/16 centres when they should be 11/16 centres. At the 13/16 inch end the bolts are offset outwards from the slidebar centreline.

Q. The end elevation gives the bracket as 1 inch wide and the slide bars project beyond the bracket.

A. The slide bars should not project outside the 1 inch dimension, they are 15/16 inch overall width.

J. Two things are said to be "correct" but they contradict each other, I will do a sketch as its easier to see the error.

The valve chest

The blind valve end is shown with a 3/16 x 40 male thread, if you look back at issue 4427 the valve chest that this is meant to screw into is shown with a plain 3/16 inch hole at each end. One end of the steam chest should be threaded 3/16×40 for the bush to screw into. If you have already made the valve chest, the blind valve end could be tapped 7/32 x 40 and the thread made to suit.

J. Fair enough but any answer on the other end of the chest, there is no gland shown for the 3/16" end of the valve rod.

A. The saddle should be made first and the cylinder clamped to it centrally back to front, i.e. 2 inch and 1 15/16 inch dimensions. It is not central the other way, or not until the Valve chest and cover are fitted. The 1 1/4 dim. is to clear the stud holes for the VC otherwise it would be the same as the other side at 1 7/16 centres. Use the saddle to drill the cylinder. If all saddle holes are first drilled tapping size, it will be easy to the saddle as a drilling jig.

After drilling the cylinder, remove the saddle and clamp the saddle to the curved top part of the horn plates. The 1/4 x 40 steam intake hole should line up with the centre of the large bush (other regulator bush) but make sure that the valve face is VERTICAL. The cylinder is not on the centre line of the boiler. It rarely was on portables or traction engines.

J.So in other words the dimensions on the saddle are wrong as I said, A corrected drawing should be issued and the cylinder drawing altered so that it reads that the 5 holes read "locate from saddle"

J. While we are talking about teh cylinder I think a passage way has been missed off the drawing as there is no way steam can get from the 1/4" brass pipe into thevalve chest, I could be making assumptions but there is no way this engine will run as its drawn!!!!

14 May 2012 at 20:30 #90841David Clark 13

Participant@davidclark13Hi There

Should have read slidebars, not slidebars and bracket.

I can't see the contradicition.

The other end gland will be shown later.

I don't know if the dimensions of the saddle are wrong.

The hole is there on my original copy but the dotted lines are missing

from the redrawn diagram.

The hole goes from the hole on the bottom right and is angled down towards the brass tube.

regards David

Edited By David Clark 1 on 14/05/2012 20:33:12

14 May 2012 at 20:35 #90842 JasonBModerator@jasonb

JasonBModerator@jasonbRight Lets see who is any good at basic maths.

I one reply Tony says gap between bars is 5/16" and overall width 15/16" but this would put the bars on 5/8" cts, this is the lower of the two sketches.

In another reply Tony says Bars are at 11/16"cts, but this would mean the gap between bars is 3/8" and the overall width 1", He also said earlier that he went out to his shed and measured the gap at 3/8" This is shown in the upper sketch which I think is correct.

Please chose one or the other as both can't be "correct" Click image to see it larger.

14 May 2012 at 20:38 #90843David Clark 13

Participant@davidclark13Sorry, that is my fault.

Lower is correct.

They were drawn on what appeared to be 11/16 centres, obviously not.

regards David

Edited By David Clark 1 on 14/05/2012 20:39:42

14 May 2012 at 20:41 #90844 JasonBModerator@jasonb

JasonBModerator@jasonbLooks like our posts crossed, yes that is the elusive passageway that I made the assumption was missing, most of my assumptions are right

David is there any chance you could let me know the thickness of the "hornplate" wrapper that the cylinder saddle fits on as I can foresee an issue and it would be nice to preempt it.

I do also have an issue with the position of the valve ports as drawn but as it won't affect running will let it go.

J

14 May 2012 at 20:44 #90846 JasonBModerator@jasonb

JasonBModerator@jasonbSorry, that is my fault.

Lower is correct.

They were drawn on what appeared to be 11/16 centres, obviously not.

J. But how did Tony measure it at 3/8 about a week ago, I think the top one is right as it works so much better with all the other sizes, the bottom option throws other parts out

Can you post the original sketch, I think that the 3/8 & 15/16 sizes that appeared in the mag against the plan view were meant to be against the side view.

Edited By JasonB on 14/05/2012 20:50:03

14 May 2012 at 20:52 #90847David Clark 13

Participant@davidclark13Not all corrections are Tonys.

The centres are not 13/16 inch, they appear to be 11/16 inch but probably not.

The bottom one ties in with the original drawing.

I doubt it matters which but the width between slidebars is definitly 5/16 on the original.

Hornplates are 1/16 inch thick.

The wrapper thickness is not on the drawing but looks the same or slightly thinner.

The wrapper is 1/2 inch higher than the top of the boiler.

How the clinder fits on that I have no idea at the moment.

regards David

Edited By David Clark 1 on 14/05/2012 21:00:20

Edited By David Clark 1 on 14/05/2012 21:17:59

14 May 2012 at 21:09 #90848 JasonBModerator@jasonb

JasonBModerator@jasonbWell looking at the drawing one or the other must be wrong as that plan view shows the wide centre spacing of 11/16 and the narrow overall width of 15/16. I notice that the locating spigot on the cylinder cover at 1" dia is drawn in line with the outer edges of the bars so could well be 1" overall, not that we should work things out like that.

Is that really 11/16" !!!!! thick or 1/16". then there is an error on the cylinders curved base which will mean its scrap. Getting too late now, I'll draw it in tomorrow don't want to make a mistake. With what we have been given so far the wrapper can only be 1/32" thick

I can see how the horns will fit but can't work out how the 1/4" pipe will seal to the large top flange and connect to the regulator

J

Edited By JasonB on 14/05/2012 21:18:15

14 May 2012 at 21:17 #90849David Clark 13

Participant@davidclark13Hi Jason

Just because it is higher does not mean the radius is incorrect.

No, 1/16 inch thick.

Now you know why it took 3 years to decide to print it.

regards David

14 May 2012 at 21:27 #90851 JasonBModerator@jasonb

JasonBModerator@jasonbRight 1/16" is better and I edited my post while you were posting your reply, yes height won't be an issue but radius is not right.

Radius will be half the overall width over the outside of the horn plates.

Boiler 4"

Twice firebox wrapper thickness3/16"

Twice hornplate thickness 1/8"

thats 4 5/16 so radius 2 5/32"

To this we add the thickness of the saddle at 1/8"

Total radius to underside of cylinder 2 9/32, thats not what is on the cylinder drawing, maybe a thick gasket is needed? May be able to re machine but it will drop the cylinder centre line.

14 May 2012 at 21:35 #90853David Clark 13

Participant@davidclark13The inside radius of the wrapper is 2 1/4 inch (8/32) + the thickness of the wrapper = the outer radius.

If the cylinder is 2 9/32 that means the wrapper is 1/32 thick.

regards David

14 May 2012 at 22:17 #90855 JasonBModerator@jasonb

JasonBModerator@jasonbNo, Cylinder is 2 1/4, Which means radius of underside of saddle is 2 1/8" ,don't think you are getting what I am saying, that's why I will do a sketch tomorrow. But just to say those figures are based on the 4 3/16" O/A firebox width not the (in)correct size of 3 3/8" given yesterday which would result in an even bigger radius.

Edited By JasonB on 14/05/2012 22:24:43

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Model Engineer. › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

TurboCAD – Alibre File Transfers.

1

2

Started by:

Nigel Graham 2 in: CAD – Technical drawing & design

- 8

- 26

-

15 July 2025 at 01:38

Nigel Graham 2

-

Silver steel crankshaft

Started by:

teamricky in: Stationary engines

- 7

- 21

-

15 July 2025 at 00:25

teamricky

-

Volt/amp meter

1

2

Started by:

duncan webster 1 in: Electronics in the Workshop

- 15

- 42

-

14 July 2025 at 23:26

duncan webster 1

-

Error-Message of the day

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 6

- 8

-

14 July 2025 at 23:20

Clive Brown 1

-

Electronic leadscrew pitching error

Started by:

paulg 1 in: Introduce Yourself – New members start here!

- 4

- 13

-

14 July 2025 at 21:46

Robert Atkinson 2

Robert Atkinson 2

-

Farm Boy

1

2

…

4

5

Started by:

Dalboy in: I/C Engines

- 15

- 104

-

14 July 2025 at 21:26

Dalboy

-

Another Day … Another ScumBag

1

2

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 15

- 35

-

14 July 2025 at 21:19

bernard towers

-

Adjustable spanner thread direction

Started by:

jimmy b

in: Workshop Tools and Tooling

jimmy b

in: Workshop Tools and Tooling

- 9

- 10

-

14 July 2025 at 20:00

old mart

-

Screw cutting 1.25mm pitch on a Colchester Student.

Started by:

Kevin Nicholls in: Manual machine tools

- 7

- 16

-

14 July 2025 at 19:03

bernard towers

-

“swedish iron”

Started by:

moonman in: Materials

- 15

- 19

-

14 July 2025 at 17:46

John MC

-

Variable DC power supply?

Started by:

Andrew Tinsley in: Electronics in the Workshop

- 4

- 10

-

14 July 2025 at 17:27

Andrew Tinsley

-

Sat nag

1

2

Started by:

duncan webster 1 in: The Tea Room

- 20

- 42

-

14 July 2025 at 11:41

Bazyle

Bazyle

-

Boiler Design – issue 4765

1

2

…

8

9

Started by:

Charles Lamont in: Model Engineer & Workshop

- 26

- 201

-

14 July 2025 at 10:06

JasonB

JasonB

-

Indicators – vehicle

Started by:

Speedy Builder5 in: Electronics in the Workshop

- 4

- 6

-

14 July 2025 at 06:02

Speedy Builder5

-

buying machine tools from aliexpress experiences?

Started by:

Jake Middleton-Metcalfe in: Manual machine tools

- 16

- 20

-

14 July 2025 at 02:13

Neil Lickfold

-

Electroplating questions

Started by:

Baldric in: Help and Assistance! (Offered or Wanted)

- 3

- 3

-

13 July 2025 at 13:42

noel shelley

-

Difficulty in sourceing 2.5mm s/s ‘Full’ nuts

Started by:

Greensands in: General Questions

- 7

- 12

-

13 July 2025 at 09:22

Roger Woollett

-

Rotary valve engine

Started by:

AStroud in: Stationary engines

- 2

- 3

-

13 July 2025 at 08:49

AStroud

-

Sanjay’s Banjo Engine

Started by:

JasonB

in: Stationary engines

JasonB

in: Stationary engines

- 3

- 12

-

13 July 2025 at 06:50

Diogenes

-

I’m Under Pressure

1

2

Started by:

howardb in: Related Hobbies including Vehicle Restoration

- 17

- 31

-

12 July 2025 at 22:00

Howard Lewis

-

Help for DIY lathe build.

1

2

Started by:

moogie in: Help and Assistance! (Offered or Wanted)

- 16

- 36

-

12 July 2025 at 21:42

Howard Lewis

-

New Member From The Isle of Man

Started by:

sprocket 3 in: Introduce Yourself – New members start here!

- 4

- 4

-

12 July 2025 at 20:57

Howard Lewis

-

The Silver Swan Automaton

Started by:

James A in: Related Hobbies including Vehicle Restoration

- 3

- 5

-

12 July 2025 at 18:46

James A

-

Model Turbines

1

2

…

24

25

Started by:

Turbine Guy in: Stationary engines

- 28

- 607

-

12 July 2025 at 16:28

Turbine Guy

-

Nozzle dot dwg

Started by:

Michael Gilligan

in: CAD – Technical drawing & design

Michael Gilligan

in: CAD – Technical drawing & design

- 1

- 1

-

12 July 2025 at 14:47

Michael Gilligan

Michael Gilligan

-

TurboCAD – Alibre File Transfers.

1

2

-