I have been looking at this myself, and thouroughly endorse Micheal Gilligan's recommendation of the Hutchinson Transmission website application to have a play around with power levels, pulley sizes, speeds etc, having had a play with this recently.

My new application – looking at a belt drive conversion of a Warco WM16 mill. I am generally happy with this, but when I push it (not really that) hard, I get a severe 'shrieking' noise from the transmission area , no idea what this is (some resonance set up between the primary drive step down to the intermediate shaft and the secondary step driving the spindle?)

So, as said I have been looking at belt drive, step down of 4:1 could be a bit of a problem, 5000 to 1250RPM for lower speed range, therefore requiring around 25mm pulley on the motor to 100m spindle pulley, and around 120N or more belt tension. So twice this + overhang factor on the motor spindle, around 240N plus 20%, so 30kg or 65lb sideways pressure on the motor end bearing (at 25mm driving pulley, 5000RPM, 0.7kW), Bit concerned about motor bearing.

But for Bibnah:

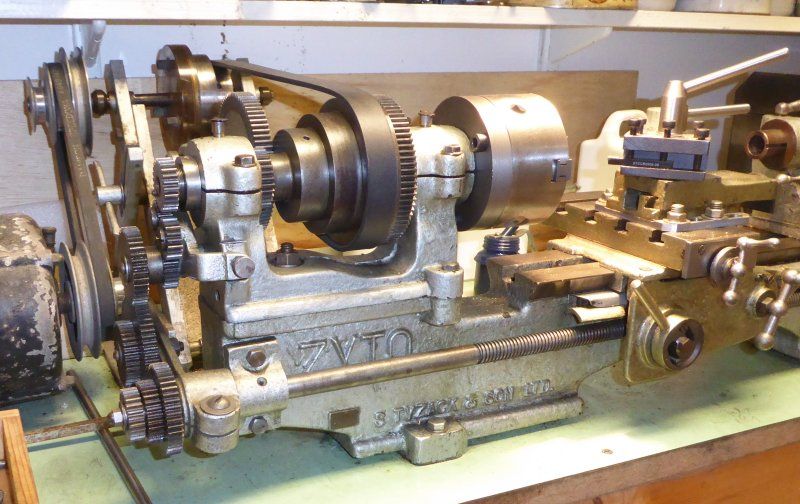

My 'middle sized' lathe is a Zyto, and iniitially came with a leather belt which was very close to falling apart at the clasp between the leather belt ends. Many years ago I replaced the belt by a Halfords poly-v fan belt, seen in photo, with ribs down onto flat puuley. It is a little slightly wider than pulley width – abolutely not a problem apart from being to wide for the smallest pulley / highest speed,step next to the bull wheel, which would be too fast a settiing anyway. The poly-v works very well on flat pulley for this light loading, and you absolutely do not need to machine your existing pulley to fit.

Martin

Roger Best.