Hi, now that everyone was so helpful on my last post I am hoping you will all have similarly helpful advice-

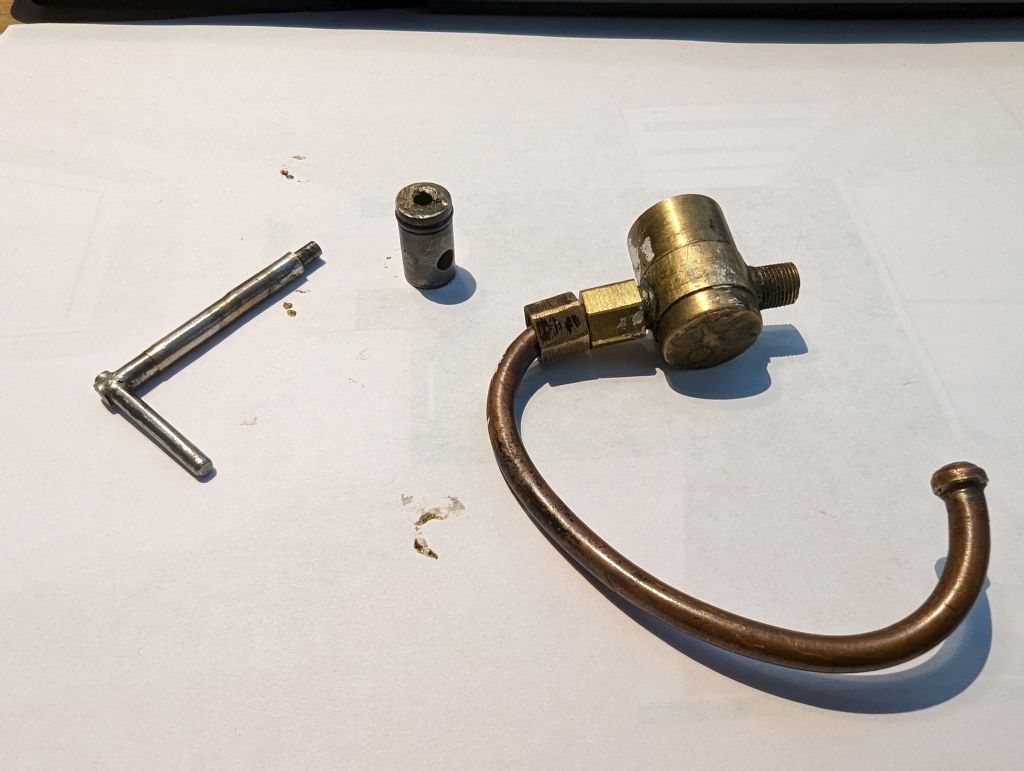

The handle on the injector water feed plug cock valve was loose and mid-steaming started to turn independently.

I decided to take it out and examine it, and indeed a gentle pull and the handle comes out freely.

Just wondering whether people have thoughts on the best way to fix, or could give their thoughts on my thinking?

What first came to mind was a straight forward replacement. My issue with this is I suspect this part was hand built and it'd be nice to try and keep the original fitting if possible.

Second thought was to temporarily remove the silicon O ring and then silver solder the handle back in place. My concern being I haven't played with soldering stainless steel yet and I have (perhaps unfounded) concerns of melting or warping the part though maybe as long as I'm careful and only heat to dull red that isn't something to overthink (but as I can't yet re-machine the part it would be disastrous).

Third thought feels as if it would be a bit of a bodge job, use a small amount of epoxy (or super glue?) to re secure the part. Perhaps this is what other people would do but doesn't feel like a permanent solution.

I think with my skills and equipment a pin would be impractical and would not provide much strength given the small size it would have to be.

I'm meeting with one of the friendly club members in a couple of weeks too to help out with some things too but any opinions sooner would be welcome so I can return to steaming safely!

Hope everyone is having a good weekend!

Thanks! Ed

Edited By Edward Lewsey on 26/02/2023 09:33:23

Edited By Edward Lewsey on 26/02/2023 09:34:31

Edward Lewsey.