Sorry to be late back to this – combination of time-zone and "things".

Good discussion but I'm not sure it gets me much farther than the Google search.

– I do (now) purchase most of my filament from a reputable local supplier (filaments.ca) which specialises in 3D printing. However, I can't track either the blue or the black PLA back to them through my online purchases records. In that case I probably got them at an electronics store a few blocks away which has a shelf of filament. That filament has been sitting there for some years now and I no longer use them.

– Like Neil, I keep all my filaments in seal-able plastic containers along with some desiccant.

– I do have a commercial filament drying oven which I use with ABS but haven't so far used with PLA.

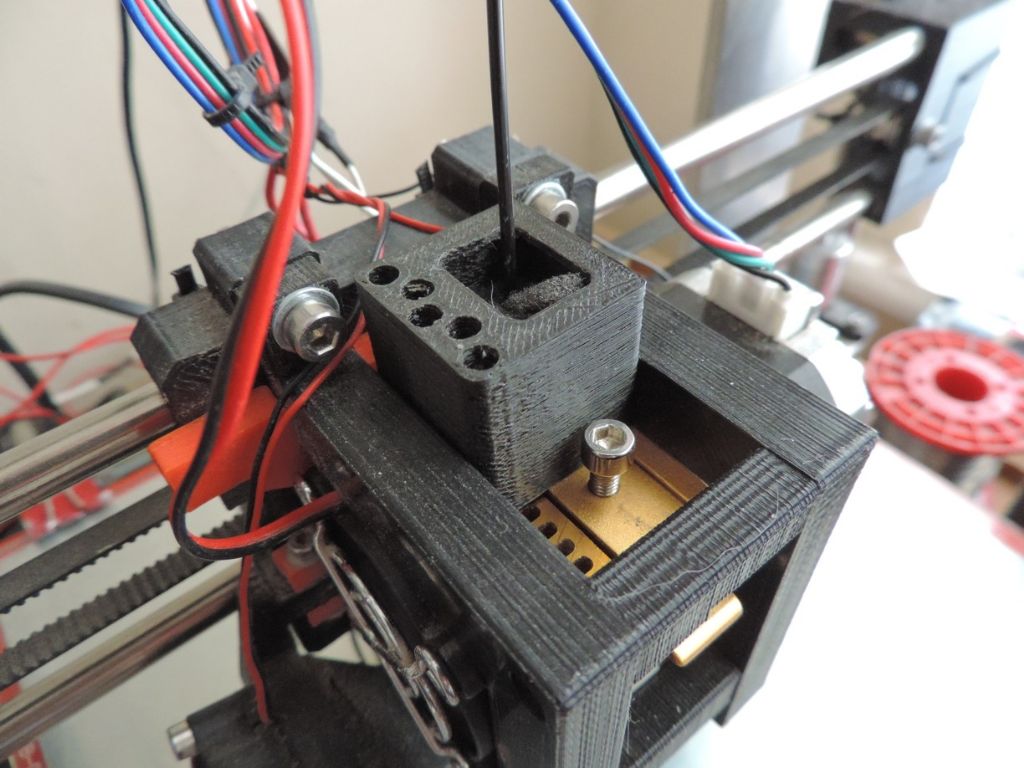

– The printers (4) are used in my workshop which is in my house basement and included in the house heating/AC system. The environment is therefore pretty benign: neither too hot nor too dry. Nor is it in sunlight.

I gather I should either keep the PLA dry …… or perhaps moist. It frankly isn't clear to me what dunking some in boiling water is supposed to show. Does it get brittle or flexible? Since putting it in boiling water must be way outside any specified operating conditions, does it actually prove anything anyway? Maybe I just didn't understand what was being said there. (I chuckled about the "meter or two" with this spool. I think the longest continuous length I could get off the spool would be 6" – perhaps less).

It seems to me that if this were a frequent problem with PLA, there would be more information out there. That the info is rather sparse suggests that, whatever the cause, it doesn't affect the bulk of the material being sold. So I guess I'll just write this off and move on (same as I did for the blue). At my age, I don't want to spend a lot of time experimenting/researching the cause of things like this.

Thanks to everyone – all the responses are appreciated.

Edited By Bandersnatch on 24/08/2018 01:27:14

Neil Wyatt.

Neil Wyatt.