Hello Howard

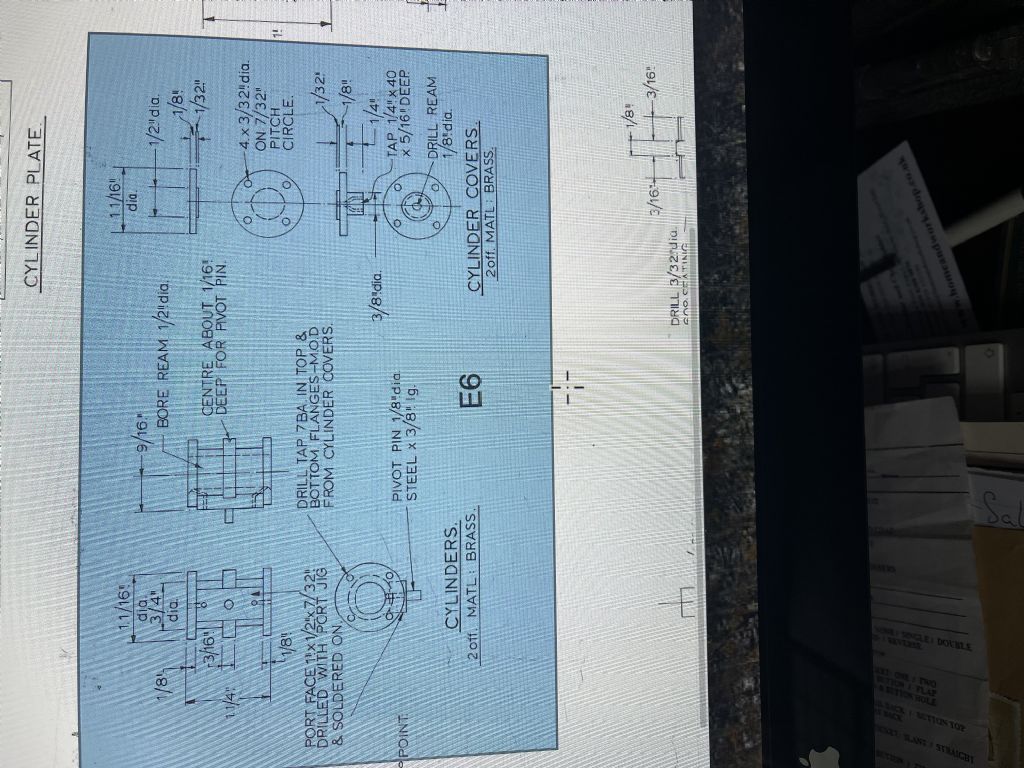

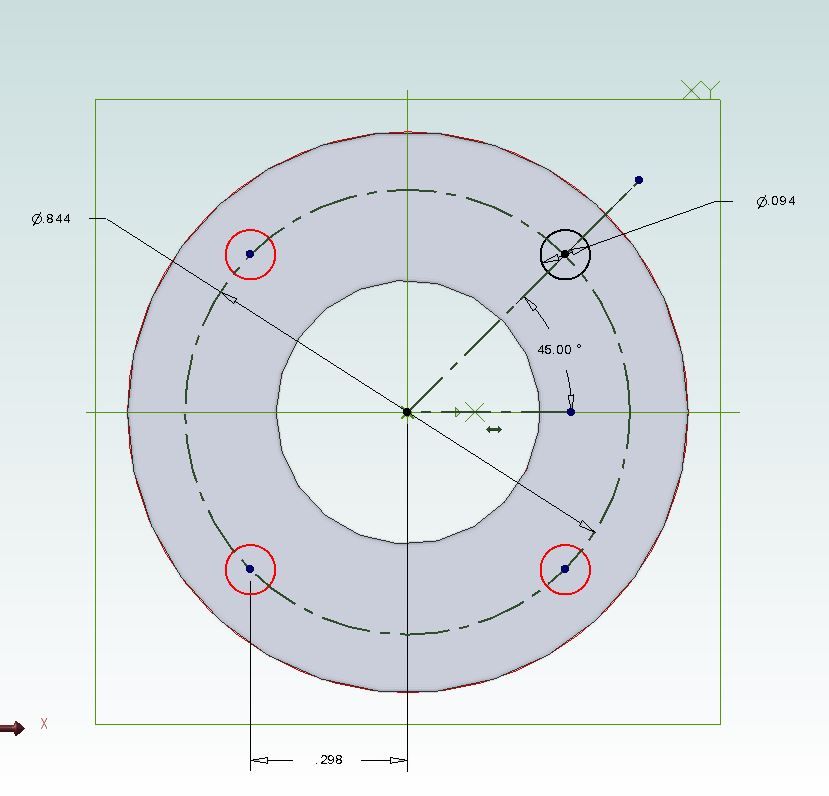

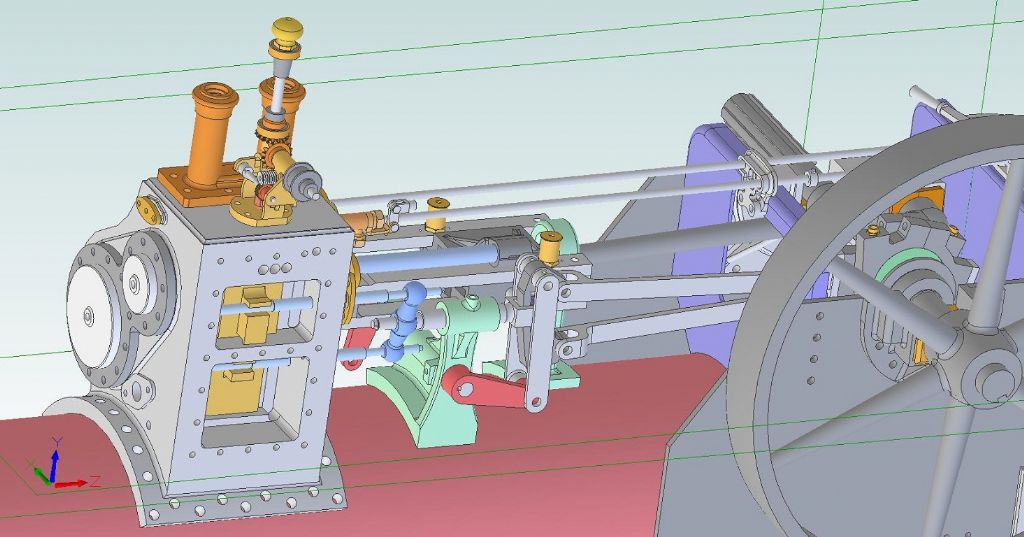

Measure twice cut once is quite amusing because I was once a cabinet maker and that was always said and used and is a good rule to follow, Firstly though many thanks to all of you who took valuable time to help someone who made mistakes by rushing in, other than the measure of 7/32 pitch circle which in hindsight I knew was wrong but did not think to challenge the mistake, I did look online first for the answer but google does hit you with so many results that you end up more confused and to be honest I did not want to ask these forums for help as compared to what a lot of you guys build this is quite small and insignificant and I thought I may not get a reply. One thing that I can take from all of this is that I watched a you tube loco build where the maker photocopied parts of drawings and took them to the workshop to make individual parts, this he said meant he stayed more focused, I thought great idea, approach the project in small pieces. All of the errors in my build only came to light yesterday once I looked at the full drawing as it was clear other than the misprint I was just building parts without any thought of how they go together, so now I use the full drawings until experience takes over. I very much like the idea of cad, I have Fusion 360 and sketchup but as always a lack of help to get going.

I have a Virginia 440,Maisie,B2 and Rob Roy all purchased as part builds which I now realise is another bad choice on my part as I have not been involved in the construction so far and that part of the learning process has already gone, I want to start the continuation of the Virginia so I would like to ask for help again as this forum has been much better than anywhere else, so has anyone built this Loco?

old mart.