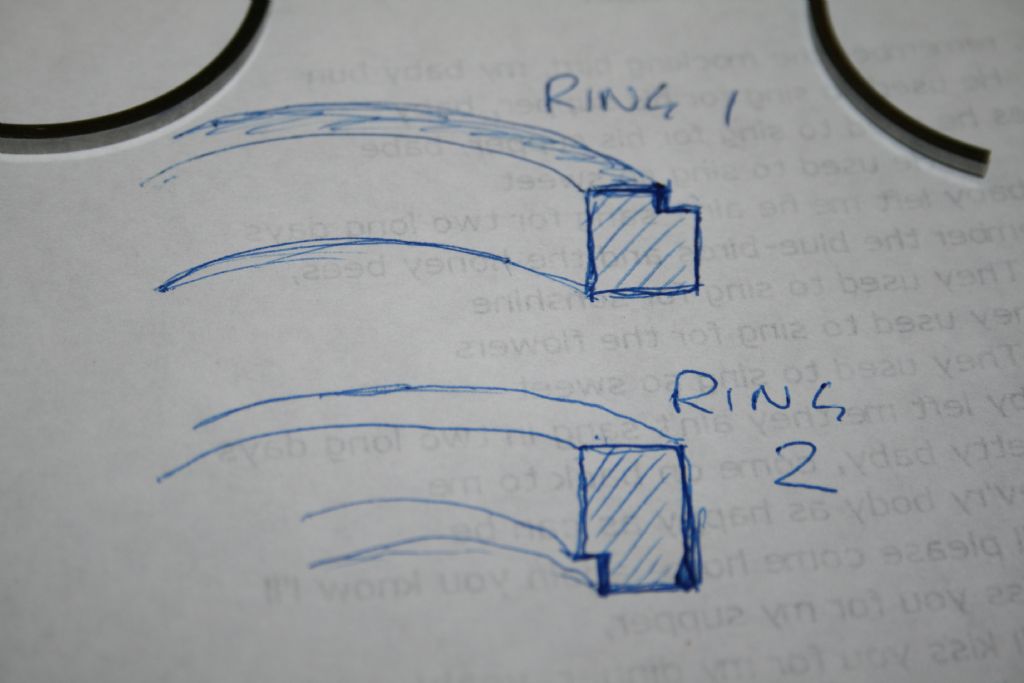

Piston Compression rings have internal chamfers or steps (usually at the top) to ensure that they twist and present a sharp edge to aid scraping oil off the bore, when descending on the power stroke.

Some rings are tapered to produce the same effect. Compression rings have a lot to do with oil control, and control of blowby.

The contact markings on the rings ought to indicate which way up they were fitted, unless so worn that they have already made full face contact., in which case maybe they should be replaced.

Many compression rings are gas backed, i.e. cylinder pressure assists the inbuilt ring load in producing the required wall contact pressure. Off load, this results in reduced friction, and fuel consumption.

For this to work well the surface finish of the side of the ring and its groove become important, as well the vertical clearance in the groove.

Nor are Compression Rings, necessarily round. They can have positive or negative ovality, depending upon the plane of the ovality, relative to the gap.

Ideally, the ring gap should be the least that prevents the ends butting together when the engine is under full load and hot. If the ring ends butt, breakage and damage to bore and piston is likely.

The usual gap is of the order of 0.001" – 0.002" per inch of bore diameter.

A Top ring with an external step at the top is only used as a "ridge dodger" to avoid contact with the unworn area at the top of a worn bore.

Oil control is a combination of wall pressure, liner cross hatch pattern and surface finish.

Many years ago engines had to be run in gently to wear off the peaks of the marks left by the boring bar.

Modern engines have the bore finished by honing, followed by a plateau hone.

Plateau honing does that before the engine is assembled, and leaves some of the helical grooves produced by the first hone, which act as oil reservoirs to prevent seizure. The correct combination of cross hatch angle and wall pressure will produce good oil control without the risk of scuffing or seizure. Get the combination wrong, and you will have problems!

The Suffolk Punch engines have no valve clearance adjusters. Like the old Ford E93A side valves, the clearance is set by assembling and measuring the clearance (if any after reseating the valves) and then grinding the end of the valve stem to obtain the specified clearance. For those who got it wrong with the Ford, there were service tools which elongated the valve stem by pressing a radiused groove into it!"

Howard

Edited By Howard Lewis on 04/06/2017 21:08:43

Eddy Curr.