Hello

I am a beginner clock maker trying to make a lantern clock from Malcolm Wild's article in Model Engineer.

I am having trouble getting the clock to run and I am almost sure that this is due to the pinions I have cut.

I am using a Thorntons cutter so I do not think that is the issue (tried making my own first) I am confused about the pinion blank diameter and depth of cut.

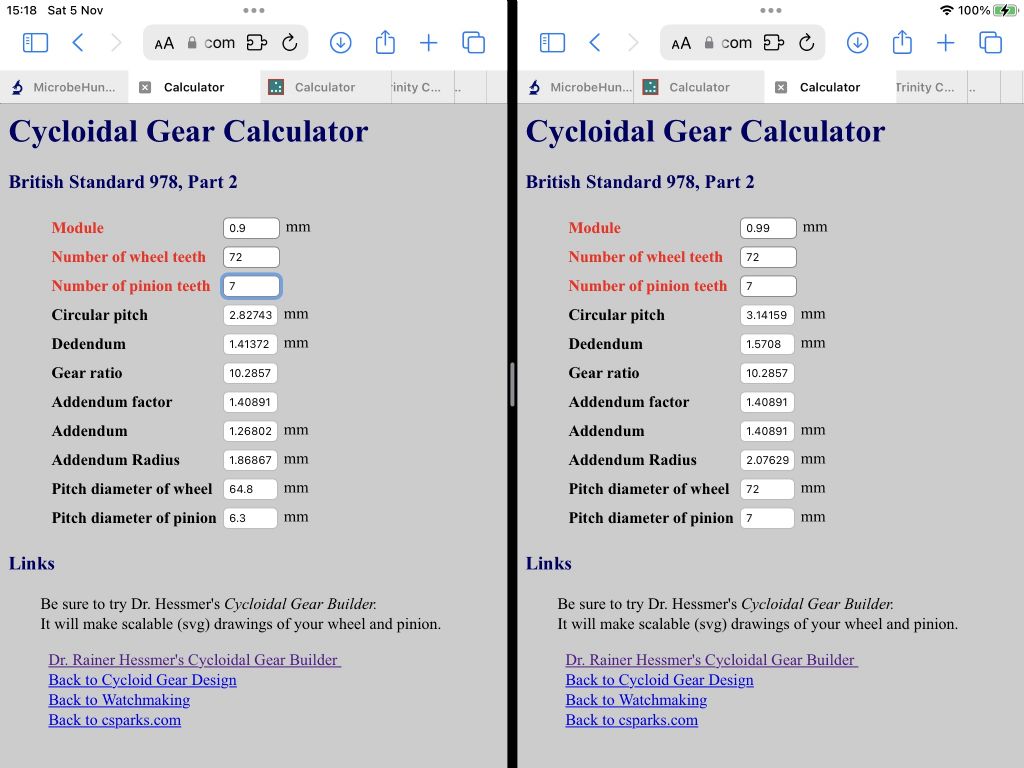

The pinion in question is M 0.9 x 7 teeth

In the ME article the pinion blank OD is shown as 0.343" whilst in Malcolm Wild's book the OD is given as 0.309"

I am also unsure about the depth of cut Should one cut until the OD diameter of the blank just disappears or should it be possible to see the original OD on the tips of the teeth?

If I start with an OD of 0.343 and cut until the OD almost vanishes the leaves are much too narrow and mesh very poorly with the wheel (M1.0 x 72)

Any advice would be much appreciated as the pile of scrap pinions is growing.

Many thanks

Andrew

ChrisLH.