I dont know the UPT, and whether you are working form plans or his book. So I apologise for Grannies in advance.

Having built his VDH, the procedure for the clamps is as follows.

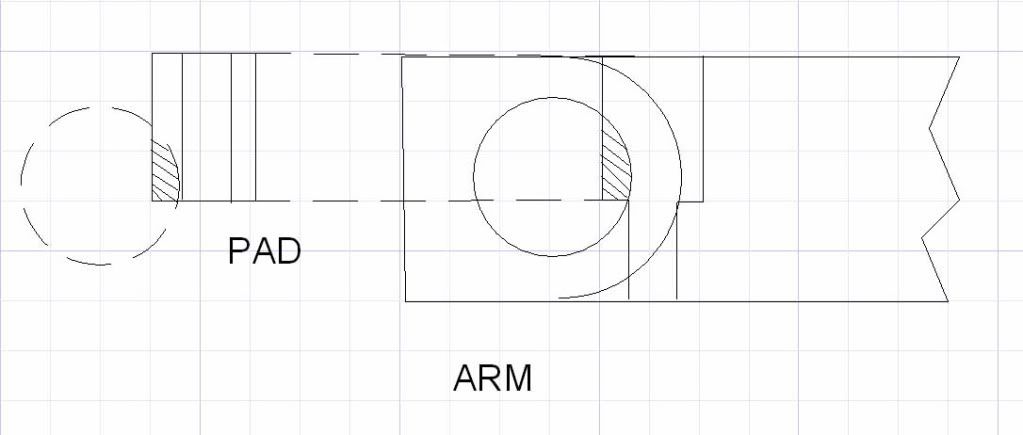

1. Turn the brass clamps to long size – see drawing for depth of hole .

2 Mark and drill the clamp holes.

3 Insert clamp blanks and lock down – drawing will show a screw hole between the pair of clamps,which is later blocked off for pulling a locking bar down – make from scrap. Or use a g cramp(s) if that suits.

4. Then bore the hole with clamps installed – you will take out the 1/2 moons in the clamps and have them all to size in one move.

5 Extract clamps, part off halves to length and insert counterbores and screw threads in appropriate halves.

6. Centre pop for identification because the clamps are “holed”. (Like only fit that hole)

DON’T try to do the bore first and then judge the cutouts in the clamps because you will never get it right, or in the right place. GHT’s way you have a perfect fit, and a guarantee that all will line up when a clamp is bottomed in its hole.

Edited By meyrick griffith-jones on 01/01/2010 17:30:40

Edited By meyrick griffith-jones on 01/01/2010 17:32:22

David Clark 13.