Posted by Robin Graham on 22/04/2020 23:25:10:

I'm planning on doing something in brass which will involve quite a bit of silver soldering. In the past when silver soldering brass I've been able to polish off the 'scale' – that pink coating [presumably Cu(I) oxide?] mechanically, but on this project it will likely be too tedious/fiddly. So I'm wondering about chemical methods.

I had a look round and found a post on a US website which recommended a mixture of Sparex pickle and hydrogen peroxide. From the MSDS it seems that Sparex is just sodium bisulphate, which I think I can buy on eBay, and I have hydrogen peroxide. The recipe I saw gives proportions, but doesn't specify the hydrogen peroxide concentration – just what you get from the drugstore!

I'm sure that there will be forum members who have trodden this path before me – any advice?

Robin.

I doubt the strength of the Hydrogen Peroxide matters much, in the UK it was sold at 10vol, 20vol, or 30vol concentrations. In all those forms it's a mild bleach and effective anti-septic.

Sodium Bisulphate, 'Half Neutralised Sulphuric Acid', is a moderately fast acting pickle and cheap to buy. It's not as quick as Sulphuric Acid, but it's cheaper and faster than Citric Acid. It's just the stuff for Copper. Safe to handle and can be poured down an ordinary drain when finished.

But I don't think it's a good idea to use Sodium Bisulphate (or any other acid) on Brass. Although it happily removes scale and oxide, it also dissolves Zinc. As brass is a Copper/Zinc alloy, removing Zinc leaves a pink porous copper layer behind. This is the dreaded de-zincification that stops brass being used to make boilers and gradually damages water fittings in some places.

I'm not sure what the purpose of adding Peroxide is. I notice customers often comment adversely about Sparex solution having a brown colour that makes it difficult to see what its doing to jewellery. Just a guess, but adding peroxide (bleach) might just be to remove the brown colour. In which case, you add however much peroxide is needed, and it's unecessary for ordinary pickling,

Wikipedia says the professionals don't use dilute acids to pickle brass. Much more exciting, they do it with 'concentrated sulfuric and nitric acid mixed with sodium chloride and soot.' Although the mixture is hideously aggressive, it doesn't attack Copper or Zinc. Don't try it at home folks!

I wonder if Cup Alloys are awake yet – they know about this stuff!

Dave

Alan Phillips 2.

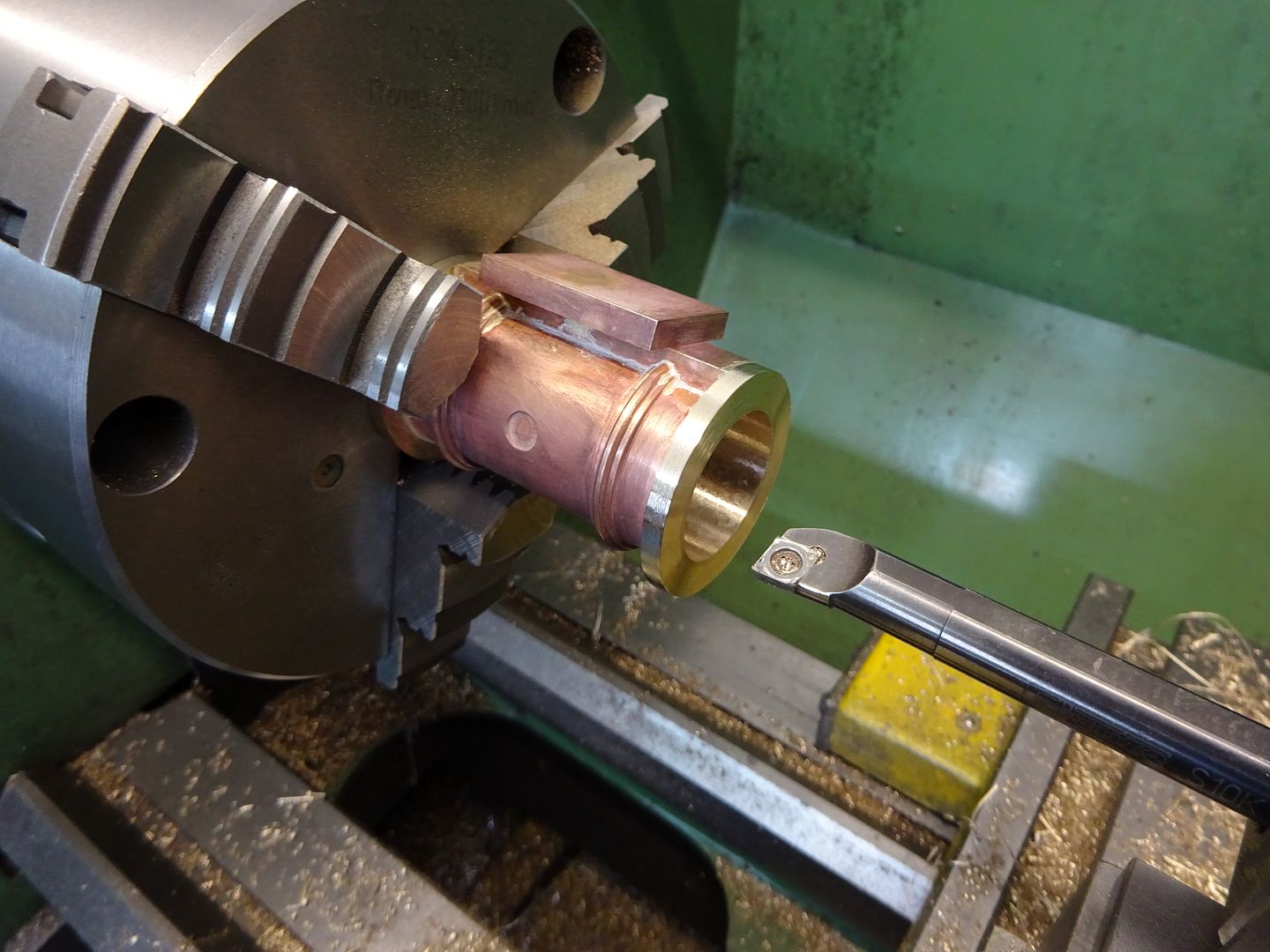

And after pickle, only bright brass is where I have been finish machining the part, rest is pink due to exposed copper on the surface

And after pickle, only bright brass is where I have been finish machining the part, rest is pink due to exposed copper on the surface