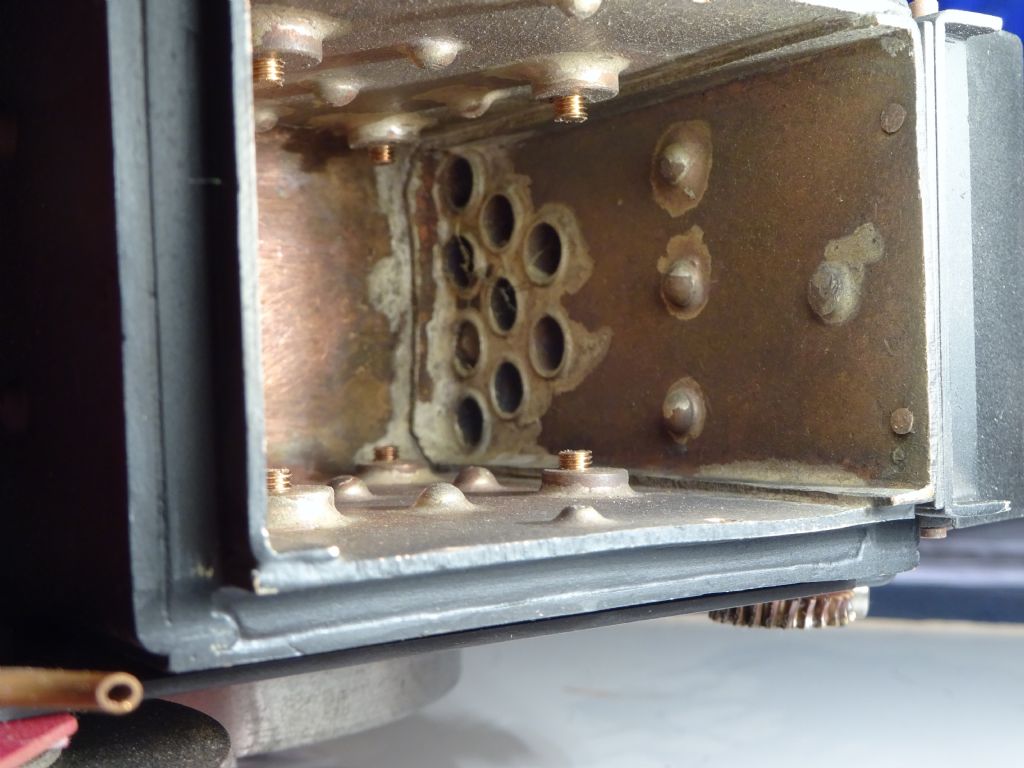

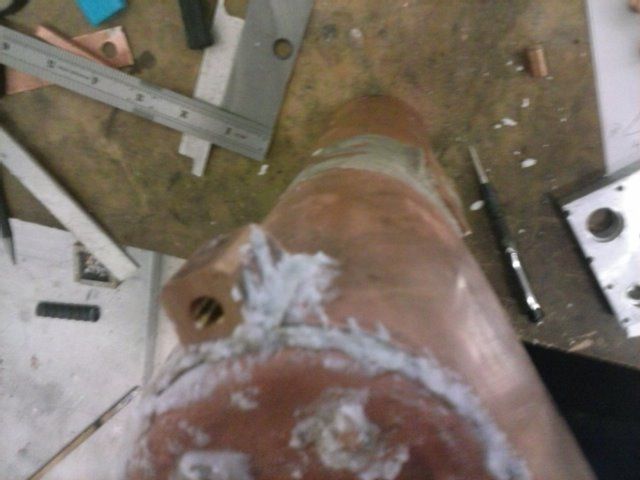

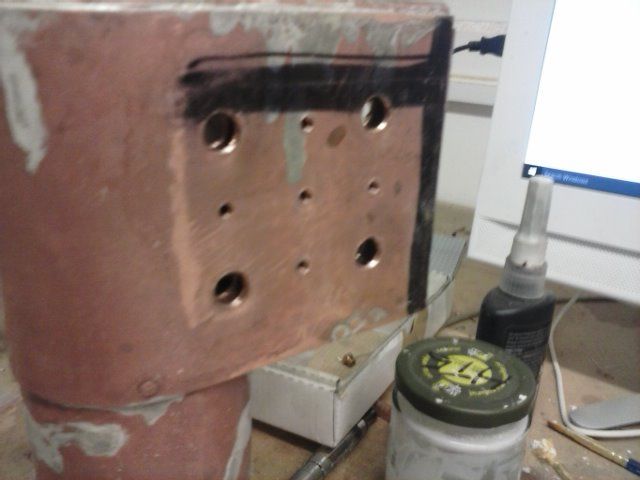

There is only one way to learn boiler making, and that is by making boilers. I admire you for doing it. All the theory in the world tends to go out the window as soon as you light that big, scary torch. The block falling off is a classic example. I had a top fitting block not fall of, but rotate slightly because the screw was a bit loose. I make bronze 5 BA screws from Colphos 5/32 hex. I avoid rivets mostly. This allows me to assemble and disassemble the parts to check and adjust fits etc.. As mentioned, don't use brass screws or rivets; you want copper or bronze. Some things are really important to get right the first time, the foundation ring being the obvious one. If you don't get penetration the first time when the joint is clean and fluxed throughout (HT5 type, not Easyflow type), it is near impossible to get penetration later. You end up relying on a coating of SS "painted" on the bottom of the ring and wrappers. You can fix a specific leak by drilling a hole for a 1/16 rivet which you then flux and drop in and solder up, but I would say that you need oxy for foundation ring "repairs". Just last week I helped a friend fix his badly soldered foundation ring, using oxy propane with a big heating tip, not a little brazing tip. We got it pressure tight in the end and it passed it's hydro, but it was a horrible job.

It is important to go to any amount of trouble when the job is cold, to help things got smoothly when the job is hot. You need the right heating equipment (with excess capacity, not barely enough), the right firebricks, the right flux, spare flux, gas and silver solder on hand, etc., etc.. This is after you have read everything you can on the subject and made practise joints and got comfortable with your equipment. You need gravity working for you, so you need to be able to move the boiler while hot. Practise this when cold with two pairs of molegrips, tongs, whatever but not gloved hands! Even two pairs of welding gloves won't save you (how do I know this?). Be mindful of damaging the annealed copper with the jaws of the grips:- wrap a bit of copper round them or something.

If at all possible, have an experienced friend to help. A second person of any sort helps enormously, to hand you things, pick up lengths of solder you drop, etc.. Wives can sometimes be persuaded!

Unless you are happy to pickle overnight after every heat, you really want reasonably strong sulphuric acid. Mine is 2 molar, but 1 molar would be OK. I bought a couple of winchesters of conc from a chemical company. It is not restricted here (Oz) but people assume it is or don't know that you can simply order it. I was a laboratory based medical scientist so I am very comfortable, but suitably careful, with strong acid.

The great thing about silver soldered copper boilers is that they are so forgiving. That is why beginners can manage it, and I am not aware of a boiler under construction having to be scrapped at my club.

pgk pgk.