Hi pgk pgk,

I'm following your progress with great interest.

Please keep up the narrative, there are probably dozens of boilers out there waiting to be completed.

The Minnie shown in my avatar, is built around a commercial boiler bought from Reeves in the early 70's when I was struggling just as you are. My intention, however, is to complete the boiler that was started way back.

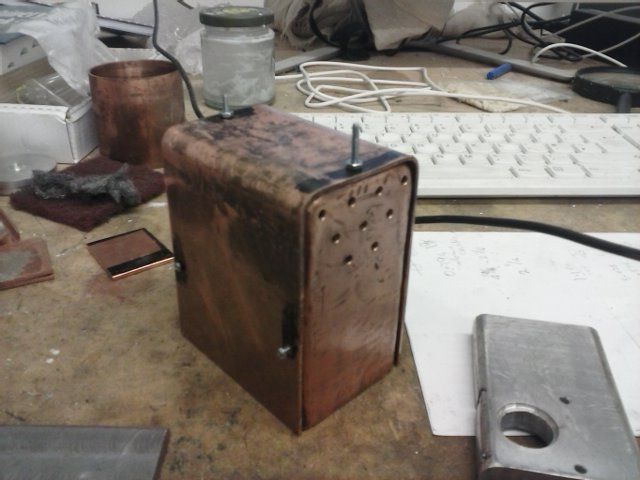

I had managed to silver-solder the barrel, wrapper (C24), pump-pad and thickening pads with some help at night-school, but then failed miserably when I attempted the firebox on my own. I was following Mr Mason's instructions including a hearth made from an oil barrel using coke (the fuel derived from coal) for refractory material . I just kept exhausting the flux, which I think was Thessco F, because I was just too slow at getting heat into the components and not helped by the torch blowing out without warning. I remember that the instructions included turning the firebox over and doing both plates at one setting, more easily said than done.

Julian mentions an important point, in that the recommendation is for the firebox to be left open at the back so that that when the boiler is assembled it gives access to the stays for silver-soldering from inside with propane. I had enough trouble with the flame going out when just wafting it around in the hearth, let alone inside a closed firebox.

I've now completed a lot of test pieces, albeit small ones, so my next big event will be the firebox wrapper and tube-plate, when I can drum up the enthusiasm.

Regards

Phil

Edited By CotswoldsPhil on 07/05/2016 10:32:57

pgk pgk.

At least i kept all the formers instead of re-purposing them

At least i kept all the formers instead of re-purposing them