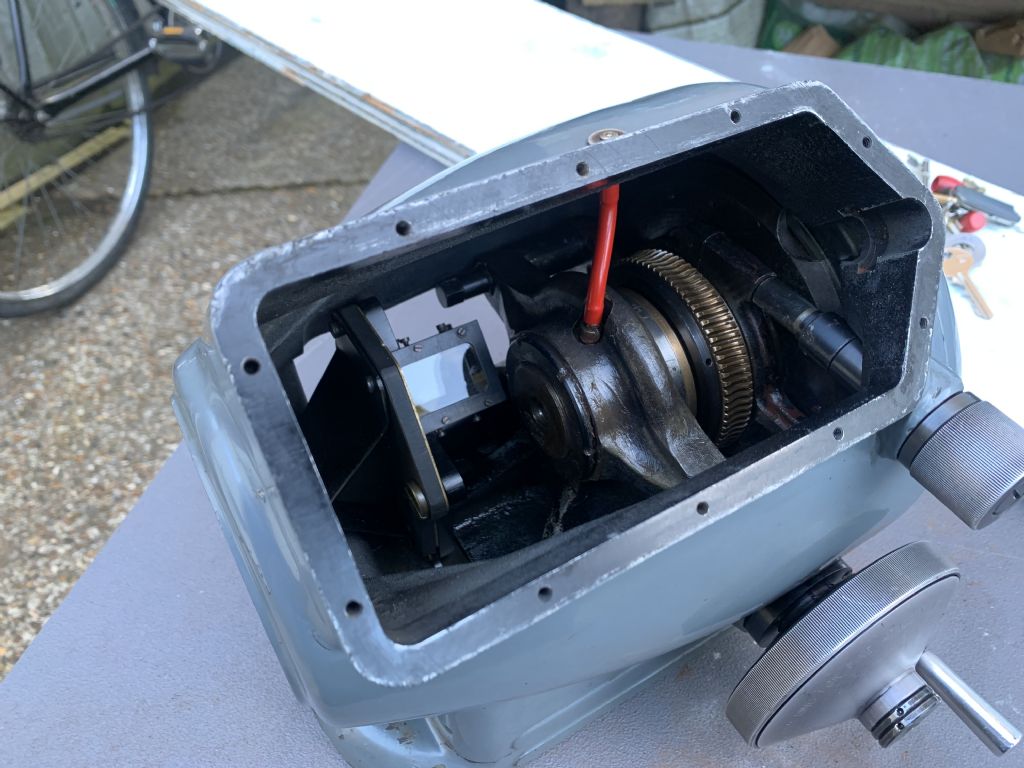

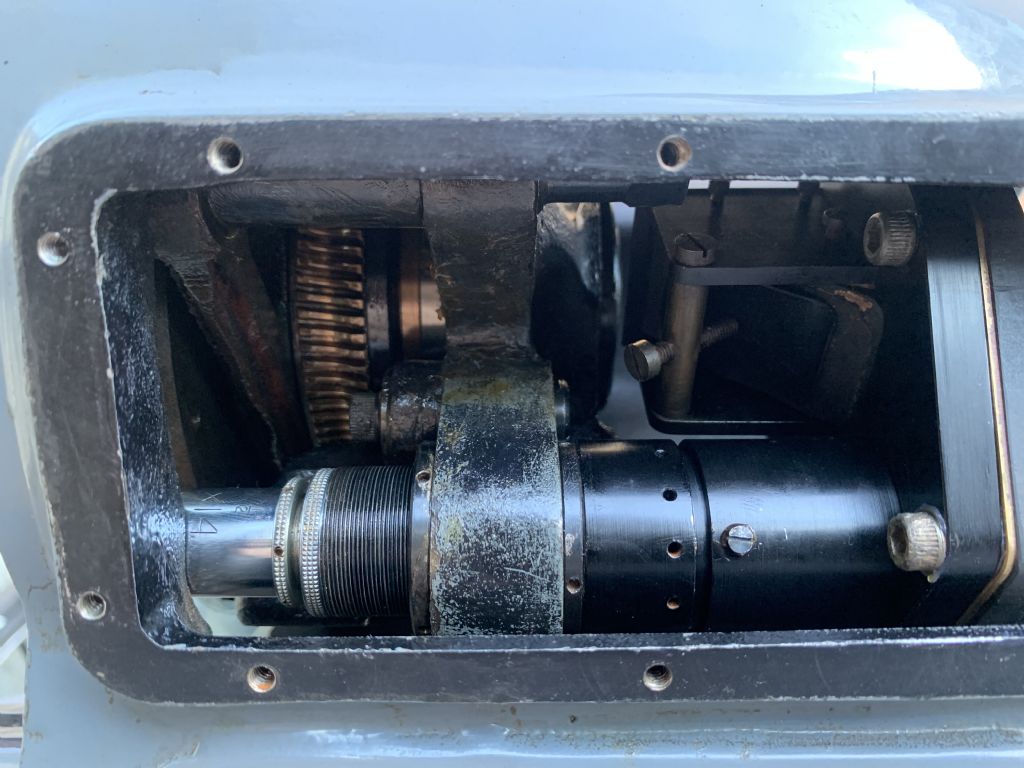

However a bit of dismantling, WD40 and a razor blade, most rust was scraped off ending up with:

(I am yet to clean to the readout assembly)

(I am yet to clean to the readout assembly)

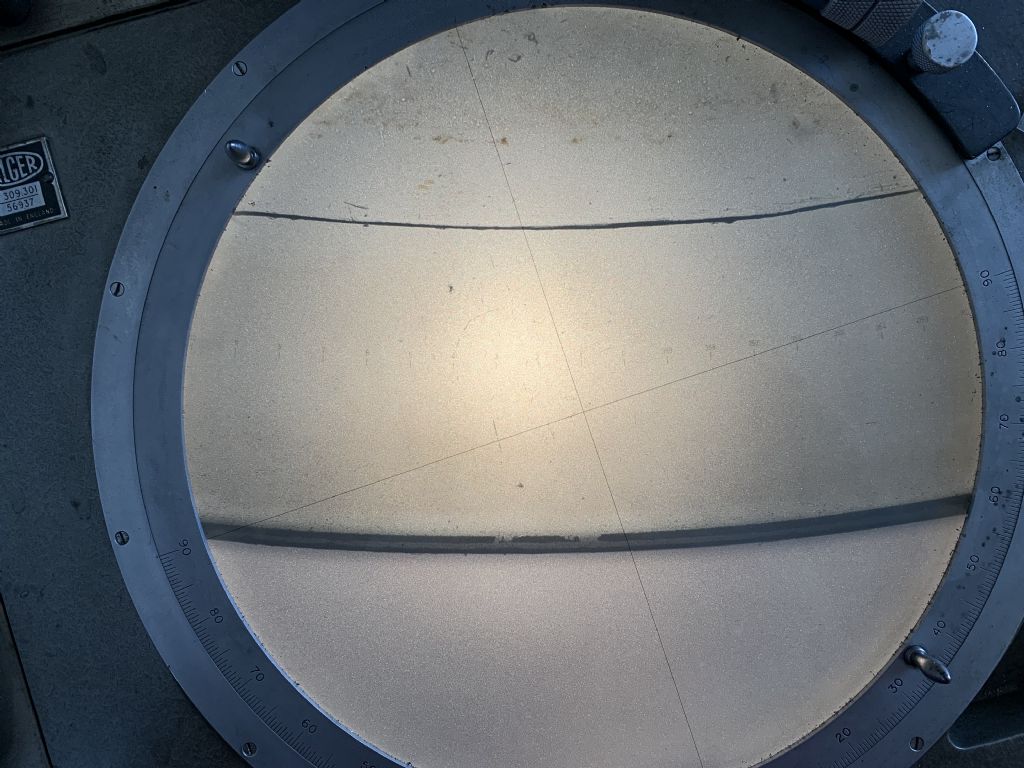

Not too bad if I say so myself! The only damaged I subjected it to was the cracked casting around the locking knob, this was not my finest hour and I am quite peeved with myself. The rust hasn't eaten in to the base metal really it had almost just furred up like scale in a kettle so was quite easily removed.

Now mechanically it is in good condition there is very little wear, helped by the rather simple yet clever oiling system.

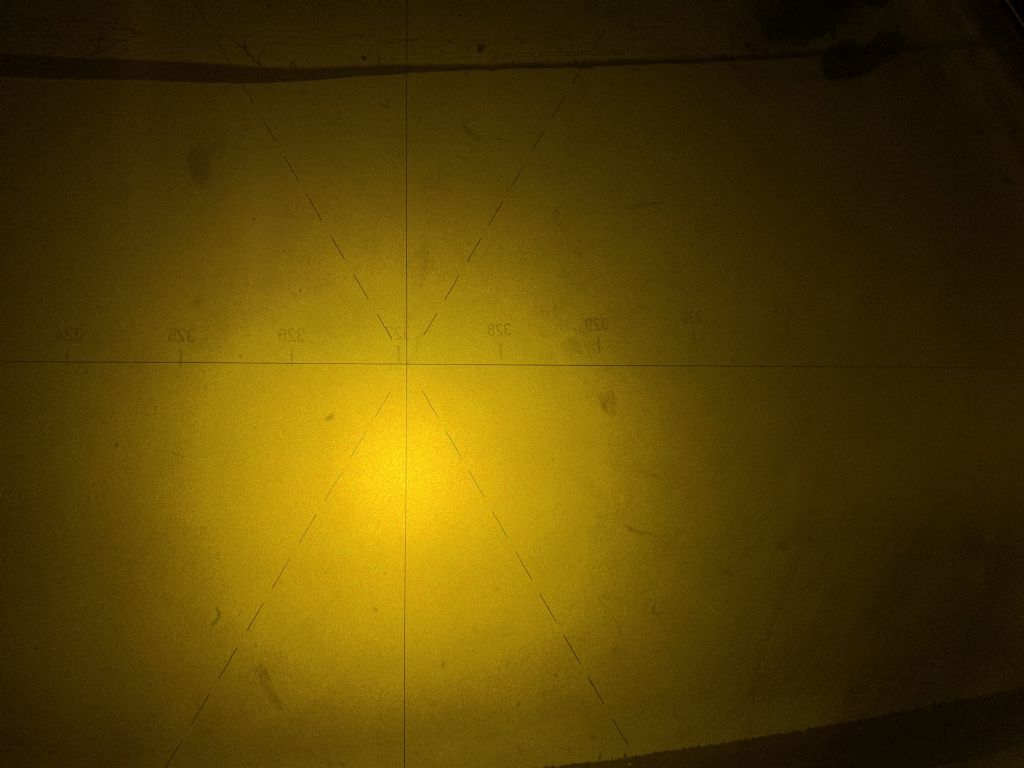

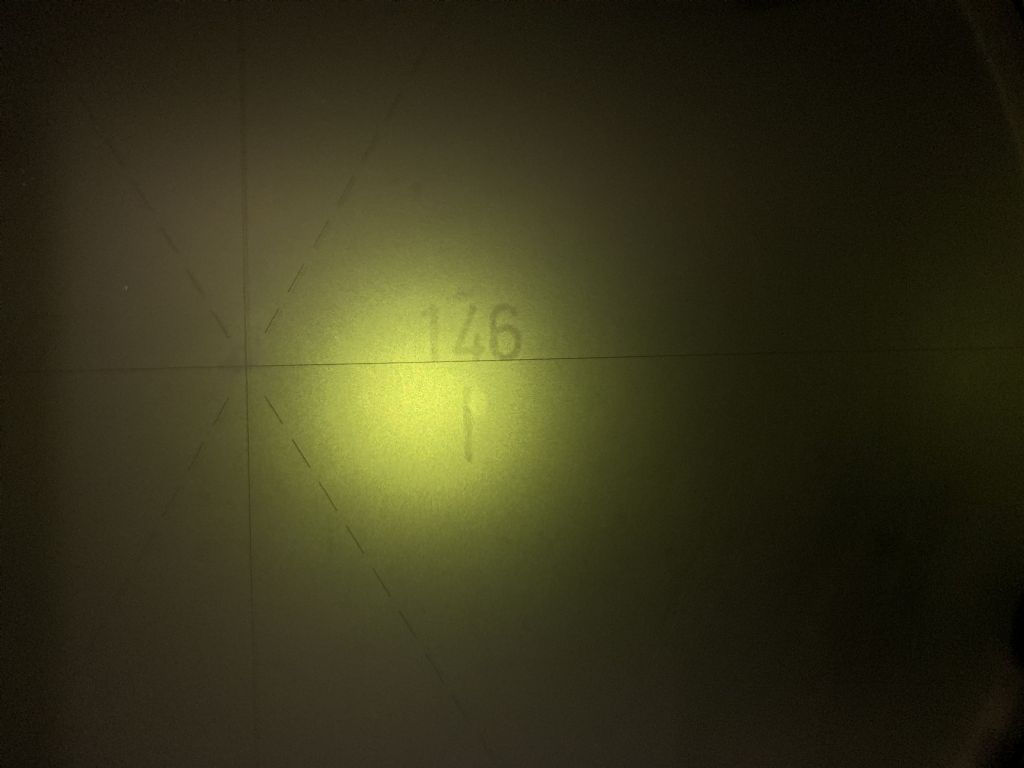

Optically however it is challenged. Its internal soaking has dissolved what I believe were water slide transfers on the glass(or could they of been something else?), The glass ring around the spindle is totally void of any markings, this was like this on me dismantling it, however the minutes scale on the was in ''good'' condition because it was sandwiched between to pieces of glass however on me separating them to clean the water staining between has meant I have disturbed the very brittle transfer and ended up with:

So basically it is useless as it stands,

How do you think it is best saved?

Could one get water slide transfers made up?

Could lazer engraving be a contender?- My worry would be precision with this method, I.E., set up in the machine etc. There is a local firm who I am thinking of talking to.

The glass ring I was thinking about setting it up on the my pantograph on a rotary table with a diamond drag tool in the spindle and scoring the glass. Again though my worry is actually getting it right as it all depends on getting them exactly 1 degree apart! (or does it?)

Or is it a really specialist task? Would a company who produces microscopes be worth contacting.

So there we go, please fire away with your thoughts! I look forward to hearing them

William

Edited By William S on 03/07/2021 20:53:53

Robert Atkinson 2.

Robert Atkinson 2.