Hi Roger,

I'm afraid I can't answer that for you. As this is my first foray into engine building, I don't know how it compares. What I can say is that Kozo's instructions are excellent, with the dimensions specified being absolutely spot on so far. I'm learning a lot of new techniques and am growing in confidence with every piece that fits. I can see why the tender gets built first now.

I have got a load more done yesterday and today (helps that i'm not working at the moment, but that is going to change next week, so this build will slow down considerably)

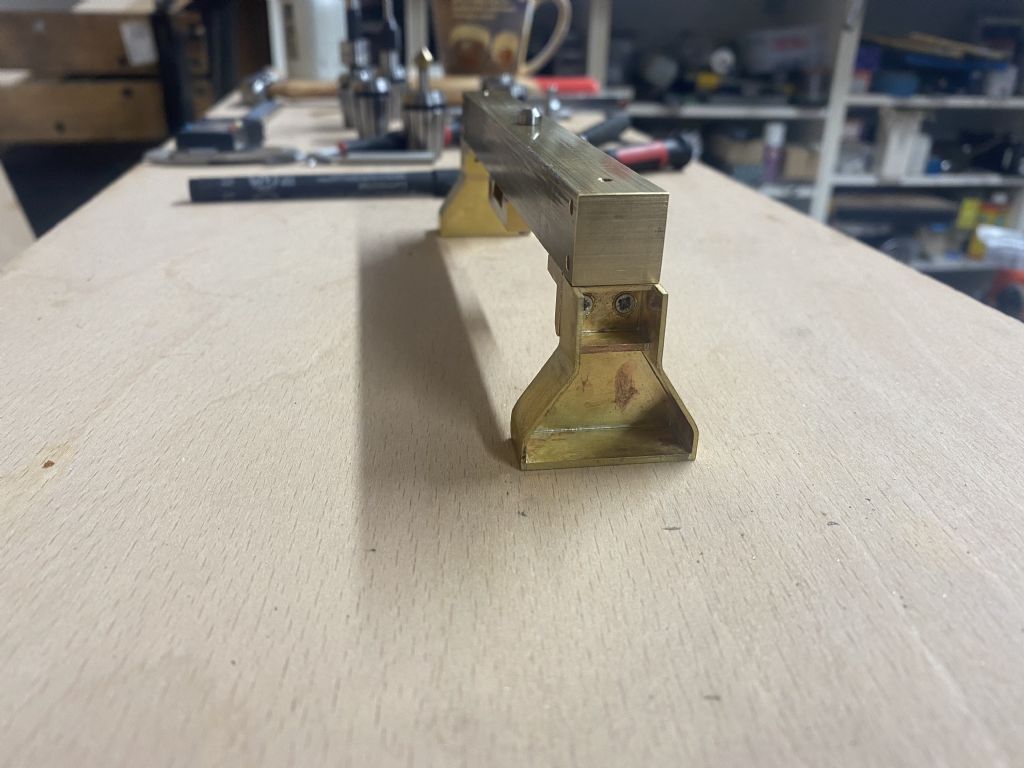

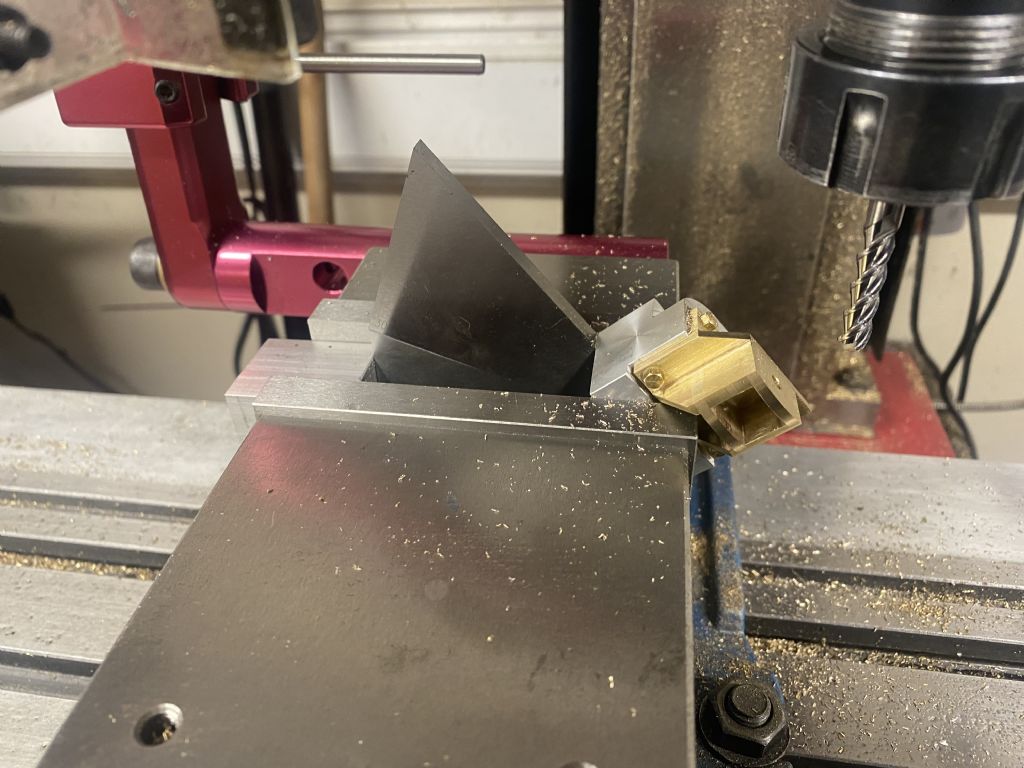

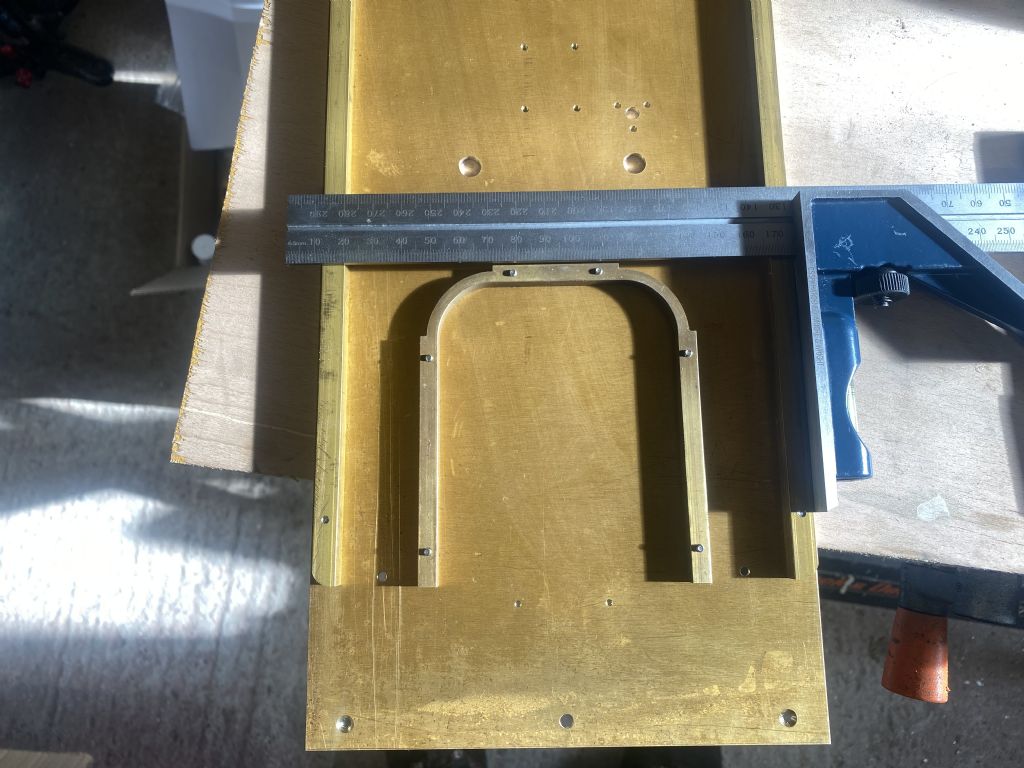

The 5/16" square for the side plate brackets turned up, so i got it to length, drilled and tapped the holes for holding it down to the bottom plate and then nicked Kim's idea of using a wood router bit to radius the ends (same router bit used for rounding the wooden former, so it should end up pretty close)

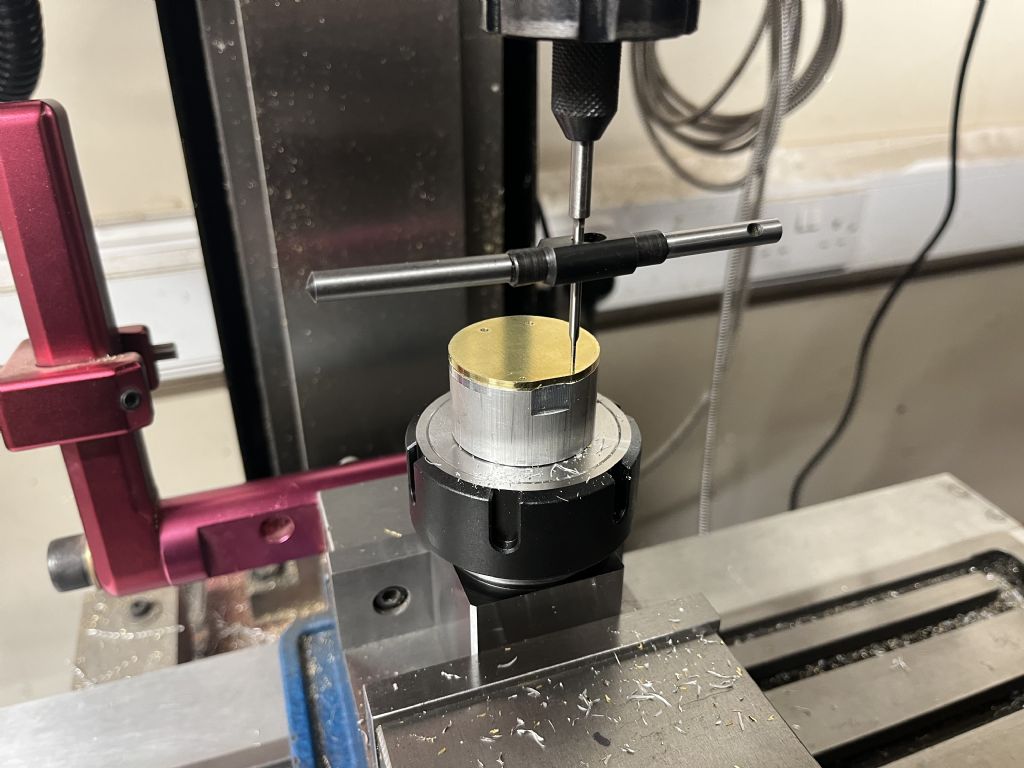

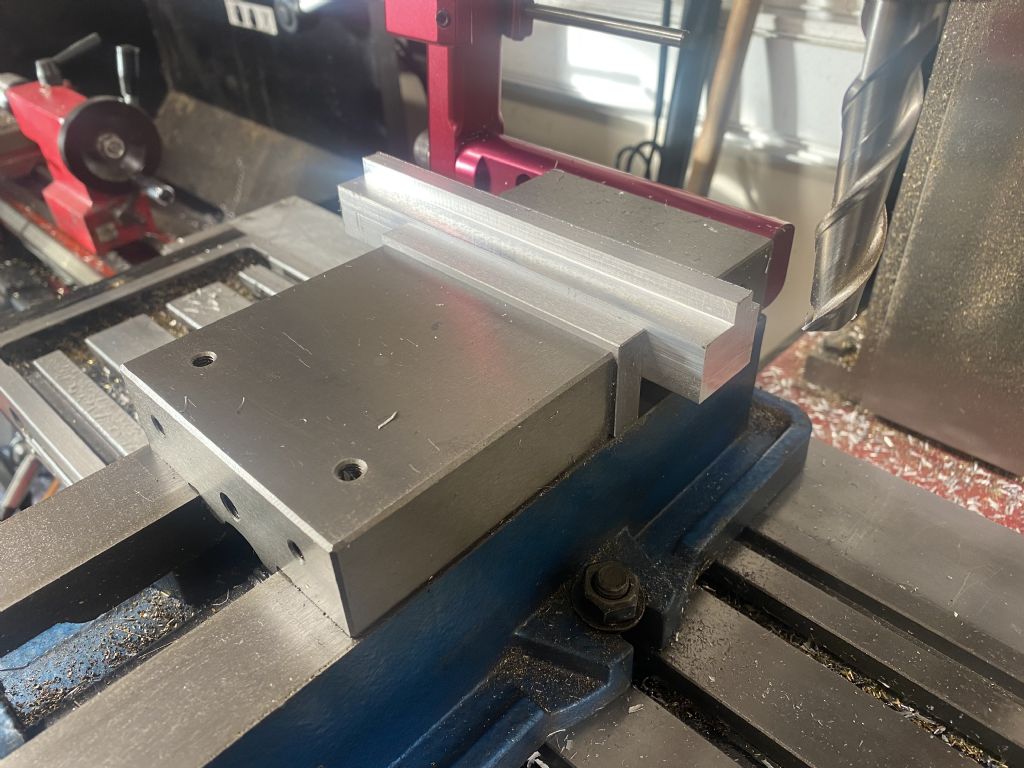

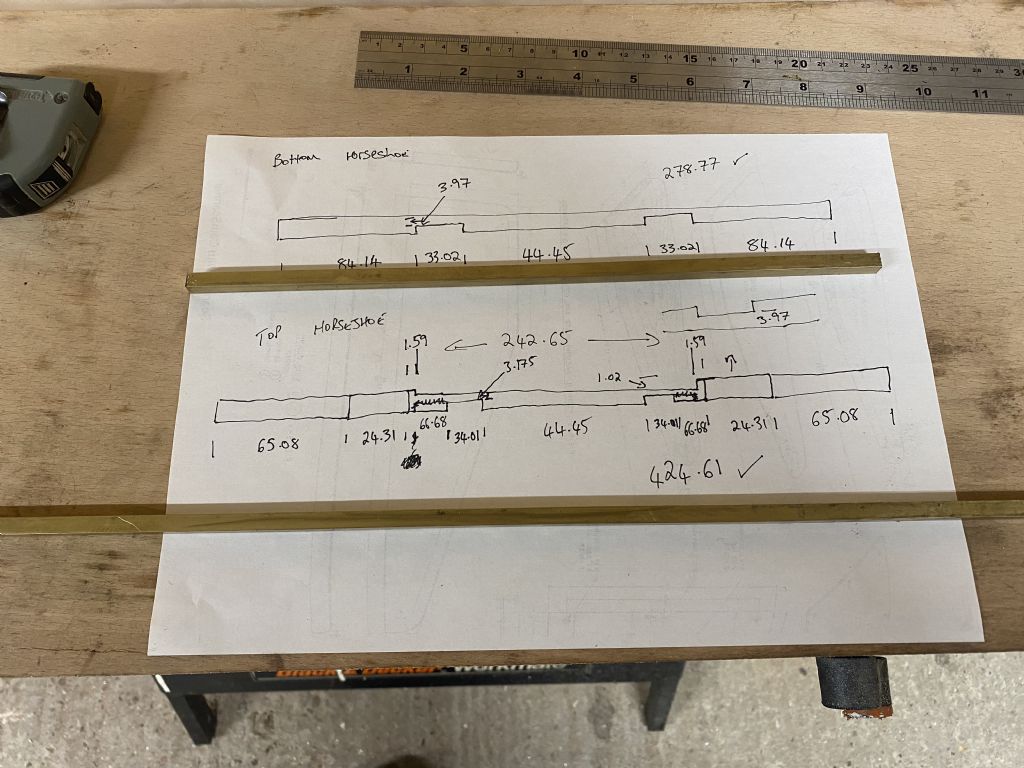

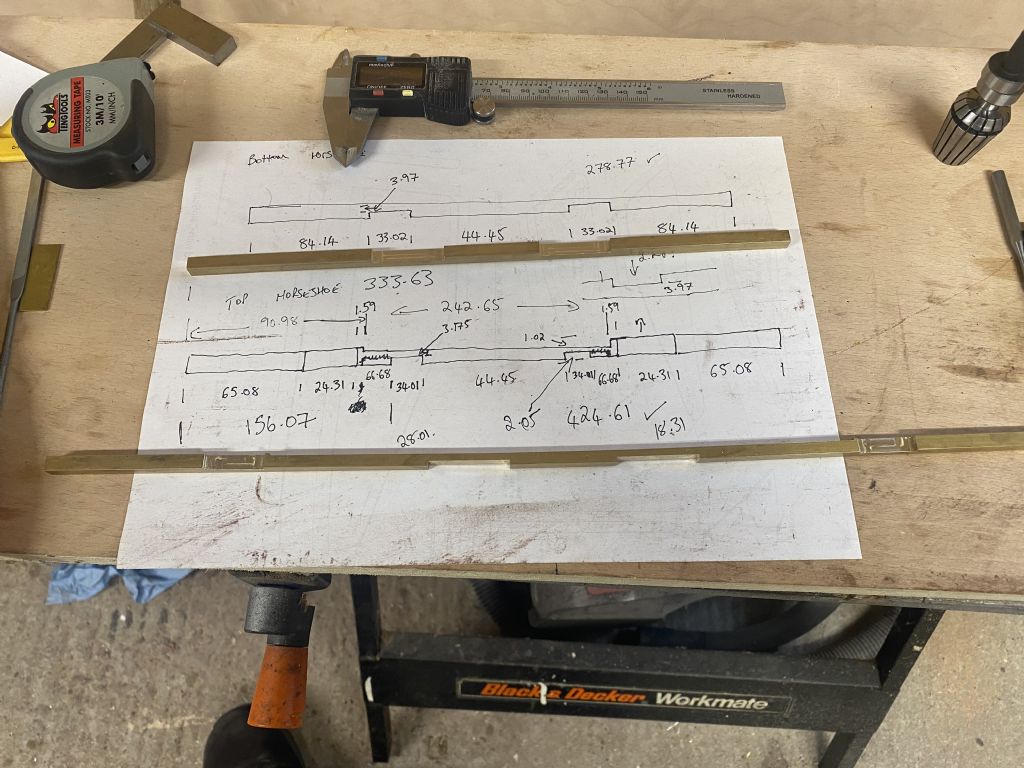

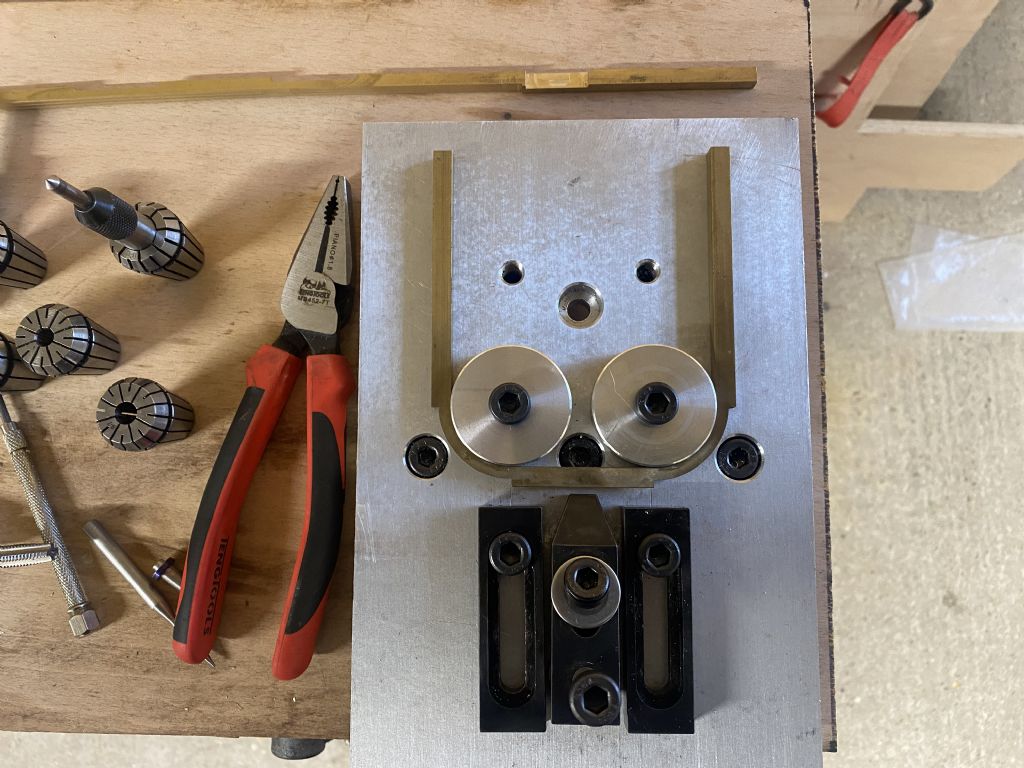

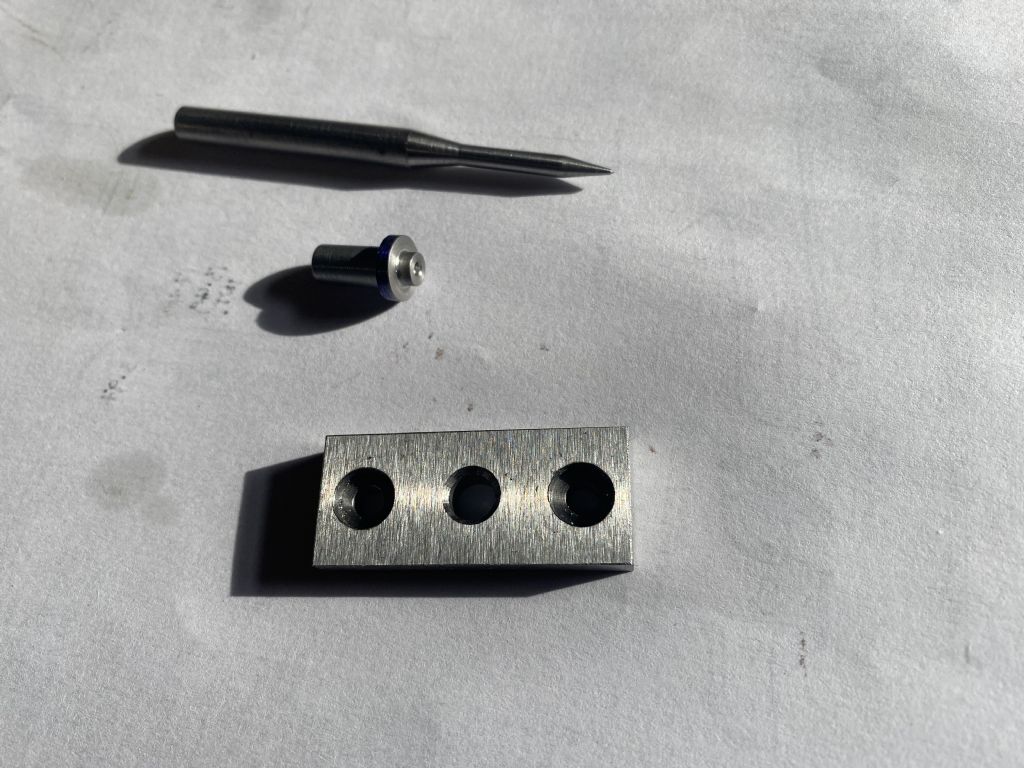

I then made up a piece of aluminium to use as a jig to hold the bottom horseshoe in the vice, then spotted and drilled and tapped the holes using the DRO to set the dimensions:

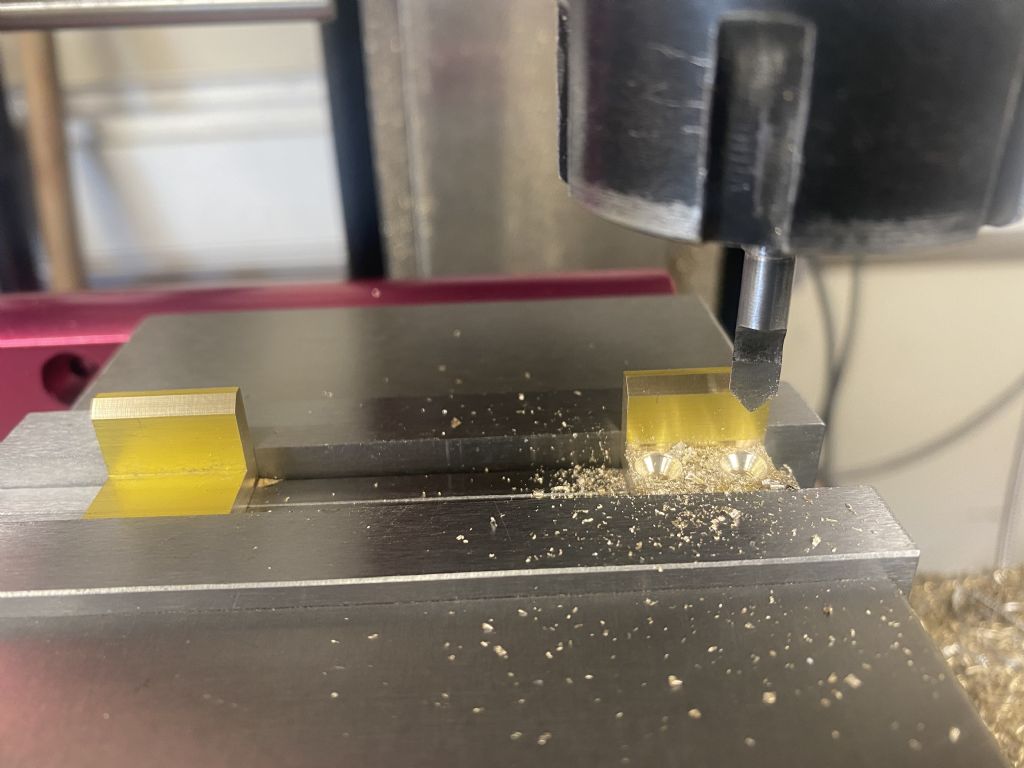

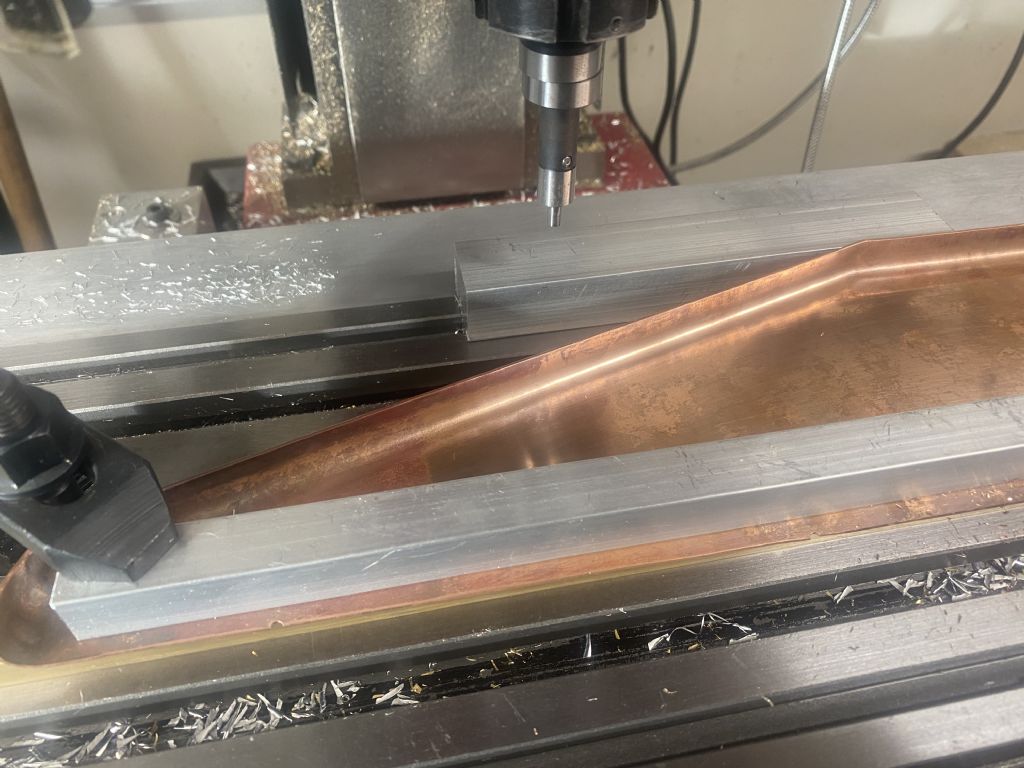

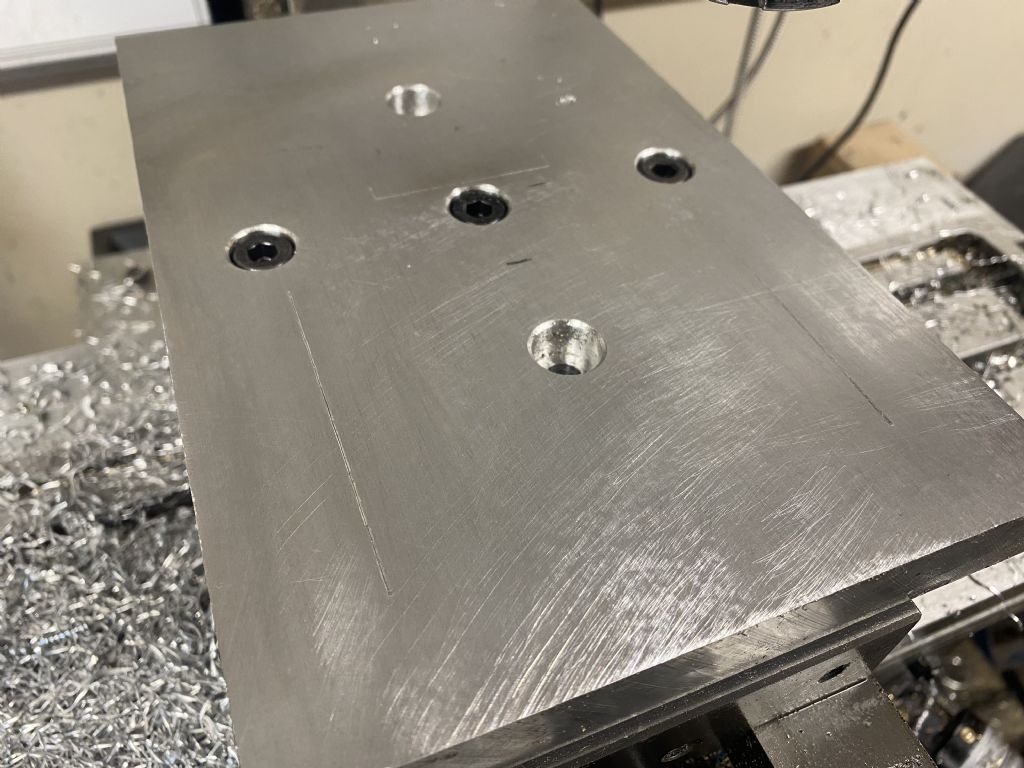

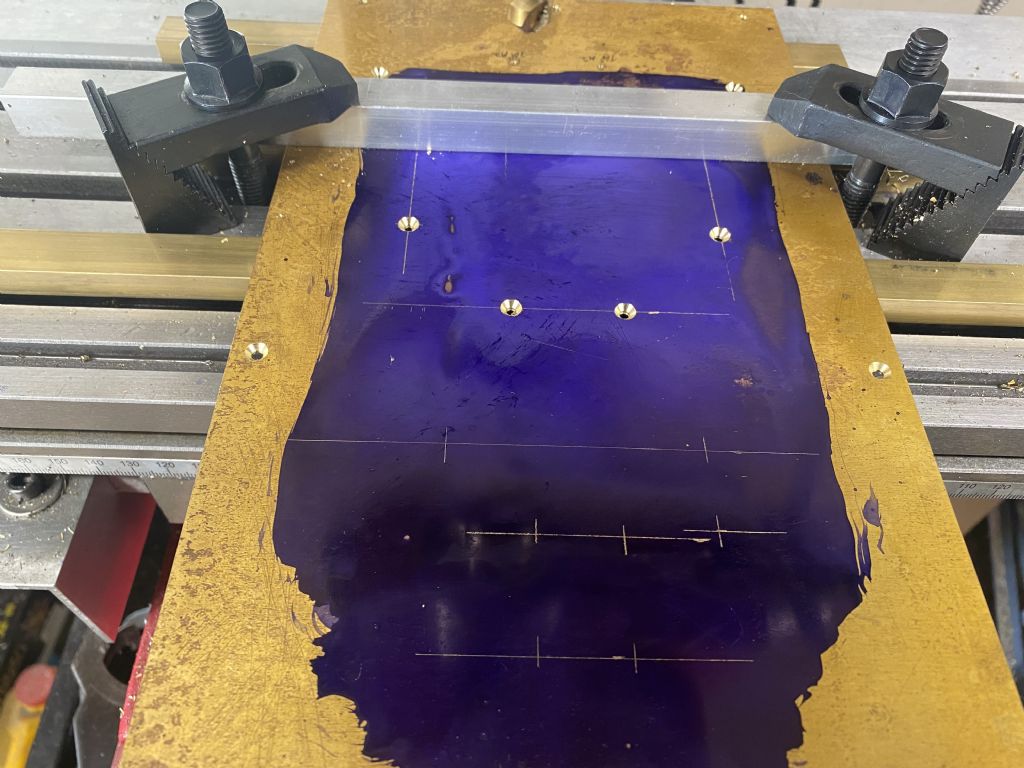

I then decided to set up and drill out the fixing holes for the side brackets and the horseshoe on the bottom plate. In the end, I decided to drill out all of the holes in the bottom plate, I was going to drill out the holes as I needed them, but its a pain to keep swapping between vice and table, so I did them all in one go. There was a bit of clamping gymnastics, but in the end, I managed to do all of the holes in 2 set ups.

I blued and scribed out the set up as a sanity check and was very pleased that all of the holes came pretty much spot on my scribe marks:

That 12.7 PCD 3 hole took me ages to get set up for on the DRO, until I realised that 0 degrees is actually on the x axis, lots of head scratching…

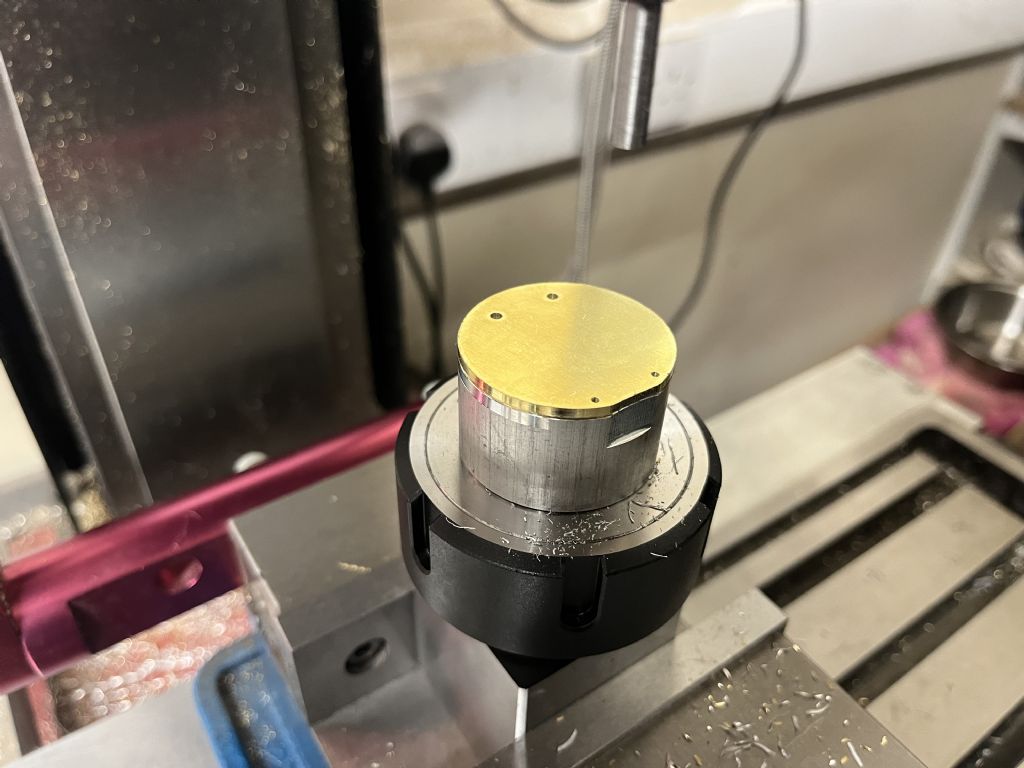

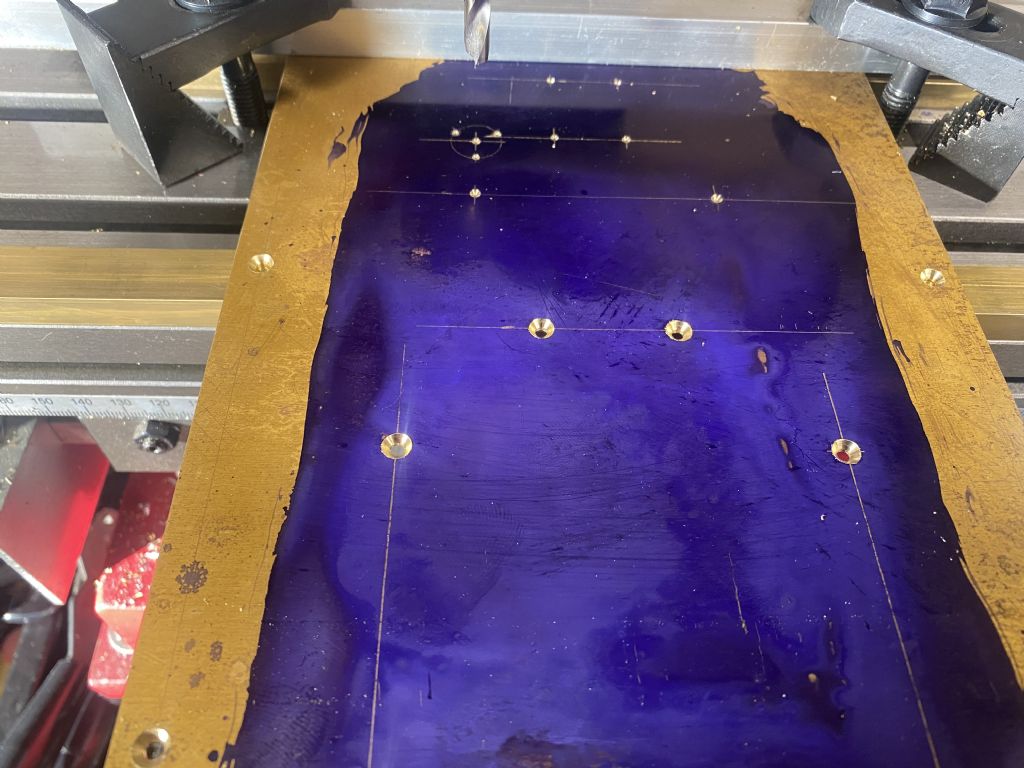

All drilled out and ready to go:

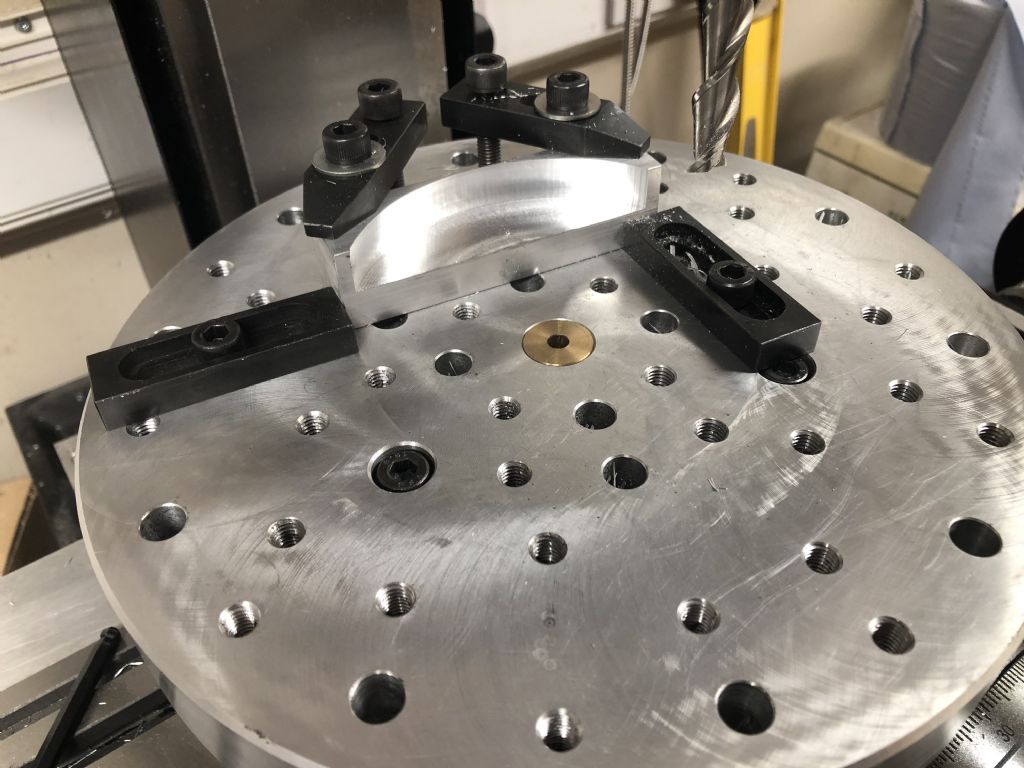

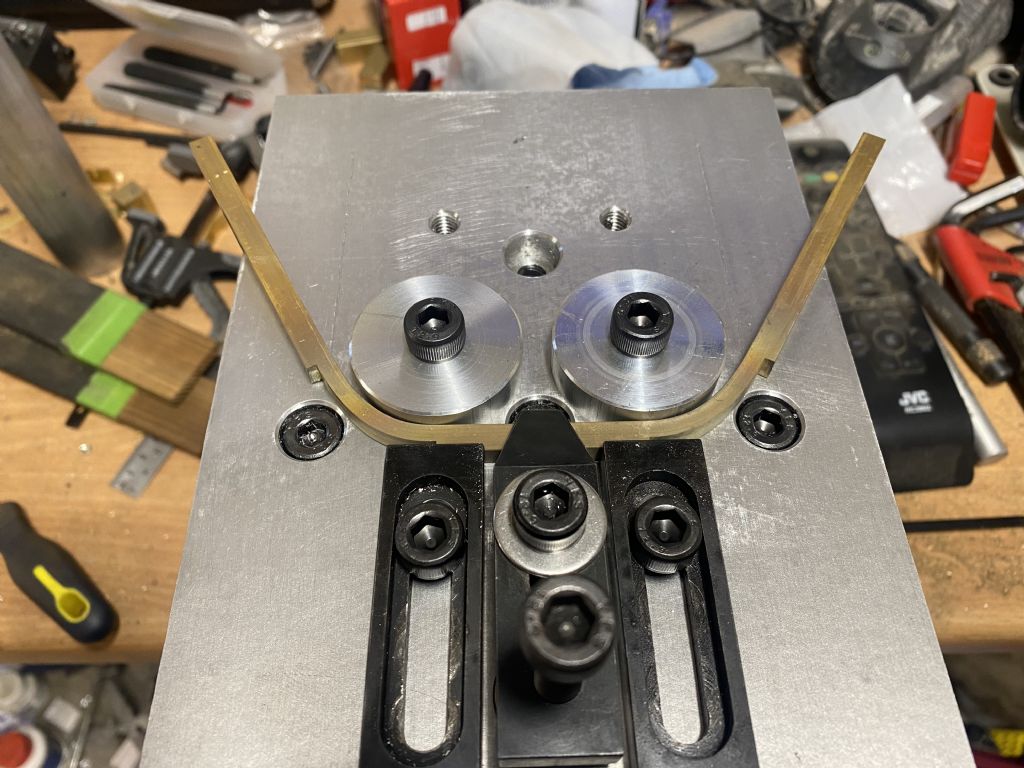

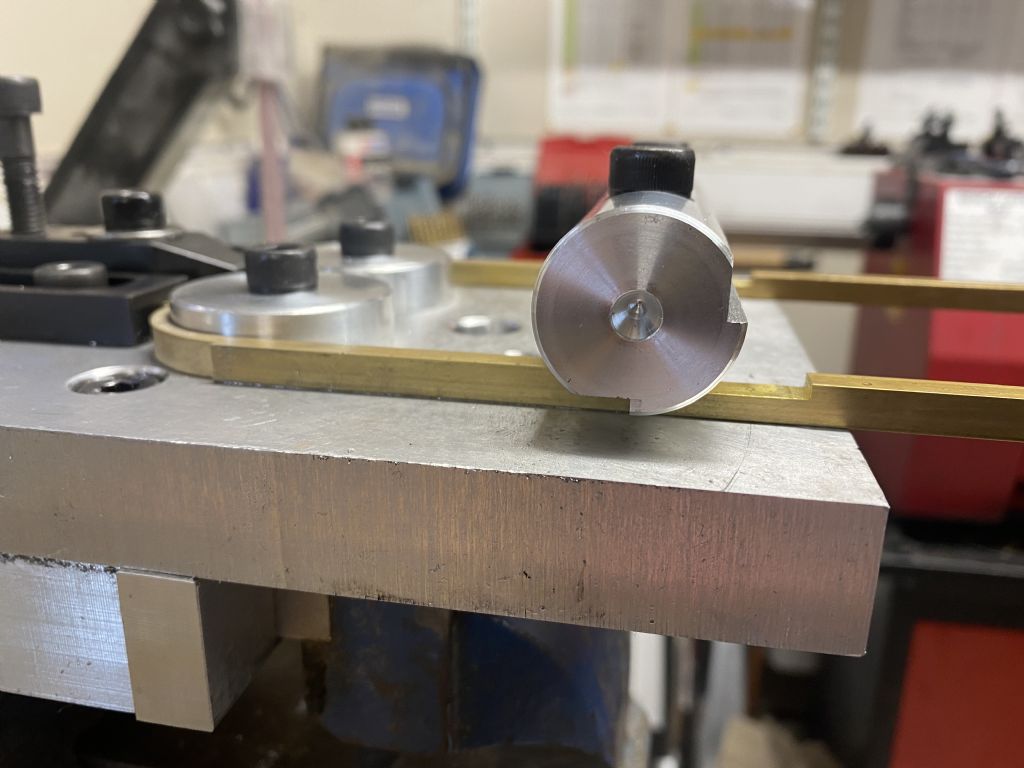

Then it was moment of truth time:

I was pretty chuffed with that, they all line up and the horseshoe is pretty square:

I made up the front little bits and the rear corner member, then had a trial fit of the sides:

Then got one side drilled, tapped and screwed together ready for soft soldering. By that time, I had had enough today.

Cheers

Mark

Mark Elen 1.

when I got the metal for the lever, I couldn’t find any 1/8” so ended up with 3mm that is actually 2.9. Upshot is, the slot is too wide.

when I got the metal for the lever, I couldn’t find any 1/8” so ended up with 3mm that is actually 2.9. Upshot is, the slot is too wide.