Hi Colin,

I built my own 'mini-router' specifically for isolation engraving of PCB's. The kind of PCB's you want to do will determine the characteristics of the machine.

For very fine tracks ( I do down to 0.4mm tracks with 0.4mm spacing between tracks..):

The machine should be as rigid as possible with 'no' backlash in the leadscrews.

The spindle should be as high speed as possible ( 20000RPM is good, 30000RPM is great), The cuuter tip is very fine – maybe around 0.15 to 0.2mm at the cutting edge, and speed is needed.

The cutter geometry is critical – D-type engraving tips made from fine-grain carbide are needed, esp if working with FR4 – a fiber-glass PCB substrate. Cutter penetration is a scant 20um to 35um, so only the very tips does the work, and if that tip grind , relief, etc, is incorrect, all you get are ragged burrs and poor engraving!

And last, but very necessary, a floating spindle makes for a good engraving! Since the engraving tip is conical, the deeper you go, the wider the groove, and the more you cut away of the copper track sides. So maintaining depth is critical. Trying to get the router table perfectly flat is not easy – the frame of the router is flexible enough that if the machine is on a table top, just the flex in the table top makes for many 10's of um twist in the router table, which mucks with your depth. And then the PCB material is not perfectly uniform in thickness either, and it is almost impossible to keep the PCB flat on the router table either – some folk superglue it down, etc, but flat is never is. So, use a floating spindle , running on a teflon foot on the pcb, and depth is fully controlled.

If you get a handle on these elements, then the process works, is totally repeatable, and makes great PCB's – I have made hundreds this way!

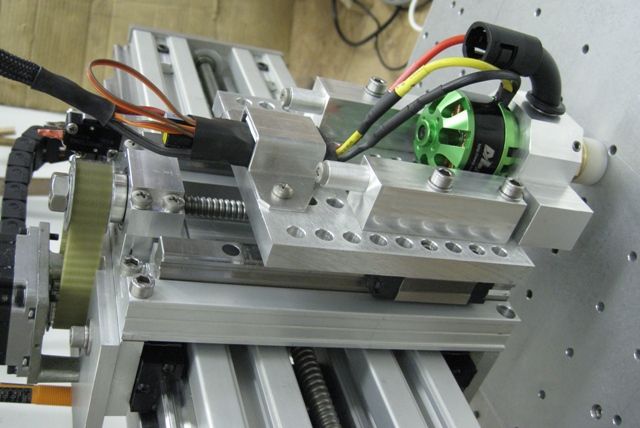

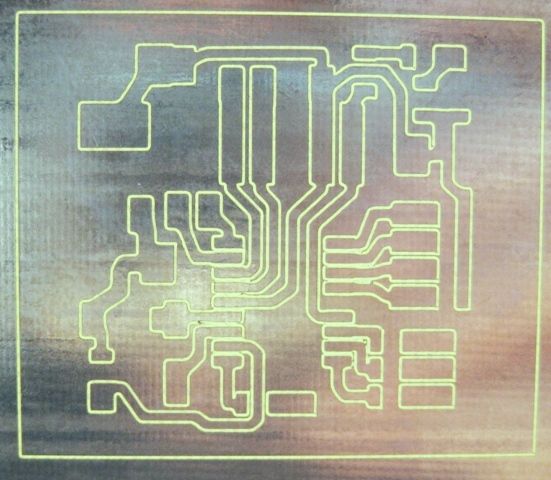

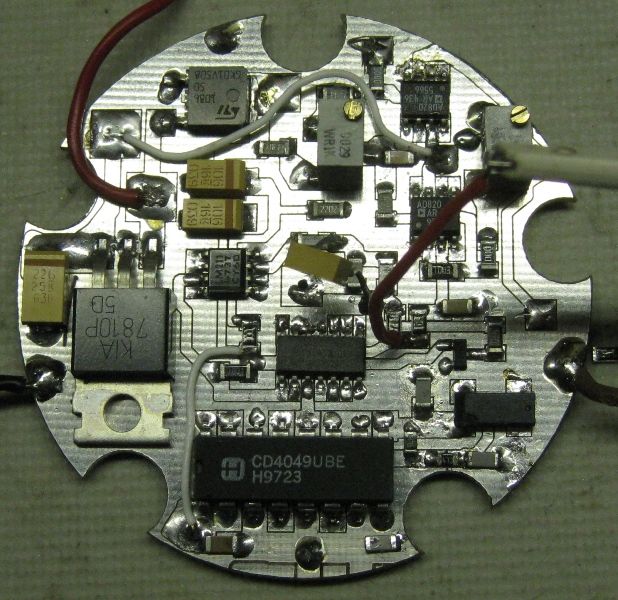

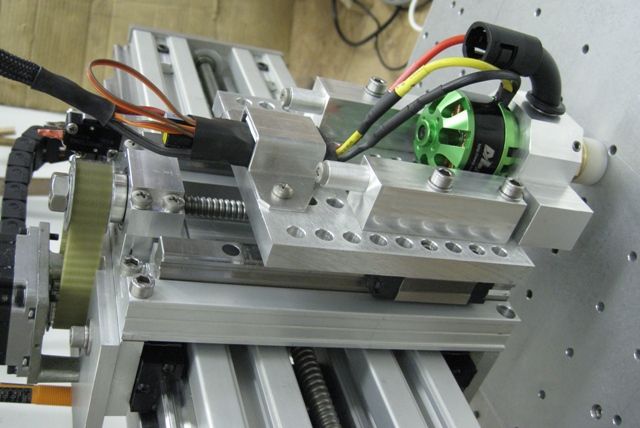

Here are some pics of my engraver and an example PCB for a very fine pitch surface mount IC..

The machine table is about 400mm long by 300mm wide – small but very rigid.

I use the same engraver to pick and place the IC on the engraved PCB using a vacuum plunger..

The tracks and pads on this IC are 0.5mm apart..

I sharpen my own engraving tips on a diamond wheel on the small T&C grinder I made.

Regards

Joe

Brian Corrie.