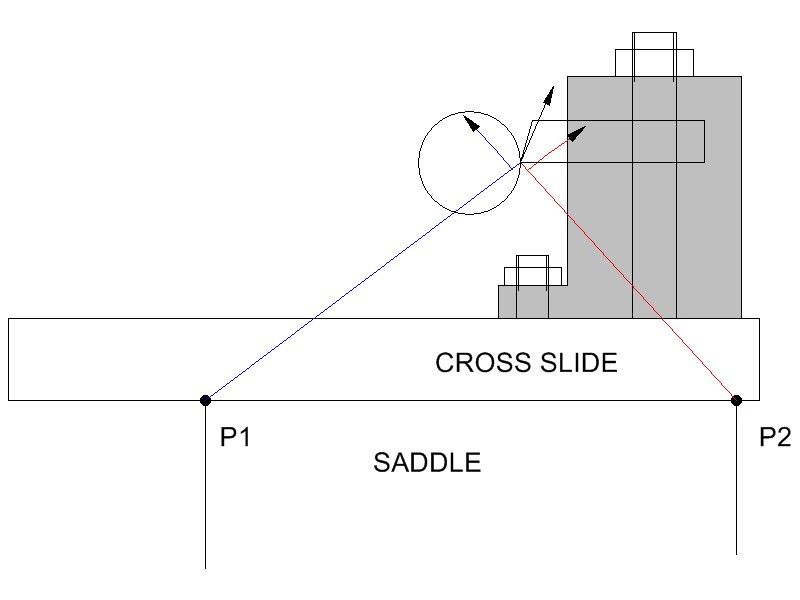

Part the Second, and another sketch:

Although the above sketch is not to scale, the relative positions of the cross slide, rear tool post and rear saddle edge are about right when parting with a rear tool post. With a solidly bolted tool post, the post itself isn’t going to pivot about anywhere, the cutting force at the tip must lift the entire tool post and cross slide assembly as one unit. Either lift it vertically, or pivot it about some point… but where?

I suggest that the tool tip can only be pivoted about either P2 or P1. It wouldn’t be too difficult to calculate this to determine which one it was in reality, once the weights of the rear tool post, cross slide, top slide and tool post were known, together with the cutting force applied at the tool tip. As far as the cutting force is concerned:

About 70 lbs for a 2mm parting blade with an infeed of 0.04mm (0.002” approx) per revolution when parting mild steel.

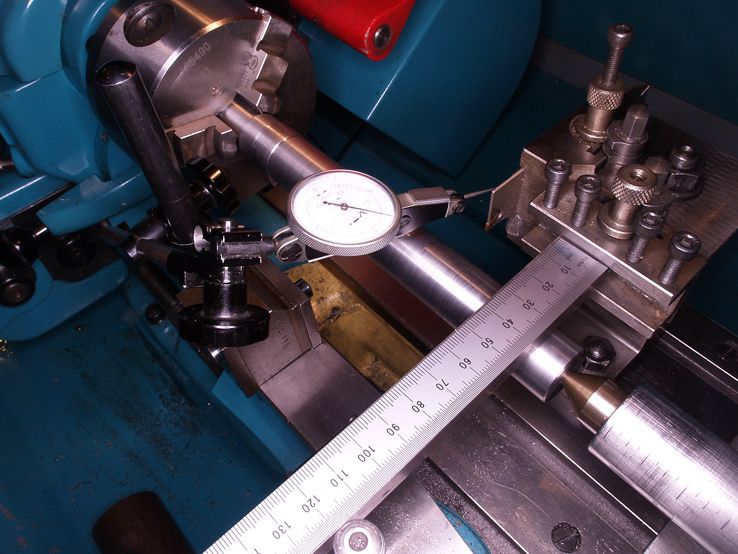

Knowing the sort of loads we’re talking about, it’s not too difficult to apply a load and determine how the tip moves. I first did this many winters ago on the S7, and have now repeated it on the Connoisseur, ostensibly for the purpose of taking a photograph of the set up, but really because I couldn’t find my results from years ago and had to re-run the tests. The good news is that they confirmed what I’d found previously. Here’s the set-up:

Something of a jury rig, admittedly, but nevertheless it works well enough for present purposes. Re. the indicator – it’s a Verdict, markings at 0.0005”, which means that tenths can be detected &estimated, but I would not claim to be able to actually measure tenths accurately with it! The results are interesting, units for the deflection readings are 0.0001”.

|

LOAD (lbs)

|

VERTICAL

|

LATERAL

|

C. SLIDE

|

SADDLE

|

|

72

|

+8

|

+4

|

5

|

0

|

|

92

|

+16

|

+5

|

7

|

0

|

|

164

|

+23

|

+8

|

16

|

0

|

Saddle lift – zero, I couldn’t detect any lift at all, so that disposes of the ‘saddle lift’ theory as to why/how a back tool post works well. At least on my lathe, dunno about yours!

Vertical lift – the figures are relative to the bed. The vertical lift has two components, i.e. for the 72/92/164lbs. loads total lift was 8/16/23 tenths, of which the cross slide contributed 5/7/16 tenths, the remaining 3/9/7 tenths coming from the Dickson tool block atop the tool post itself, presumably because of loading on the single central hold down bolt.

The lateral figures were INWARDS towards the work, not out and away from it. So the pivot point must be at P1, and the tool movement is definitely ‘up & IN’, as per the blue lines on the sketch above, not ‘up & OUT’ (red lines).

The results are, of course, for static loading of the tool post. I’ve done some dynamic tests as well, the vertical results were in reasonable agreement with the above, the lateral results showed no movement one way or the other, but I’ll discuss those further when we’ve looked at the front tool post.

Mark C.

per rev.

per rev.