Posted by JasonB on 07/08/2015 07:46:26:

Posted by Ian Phillips on 06/08/2015 21:51:31:

Jason

My confusion knows no bound, where is the sketch you are referring to?

Ian P

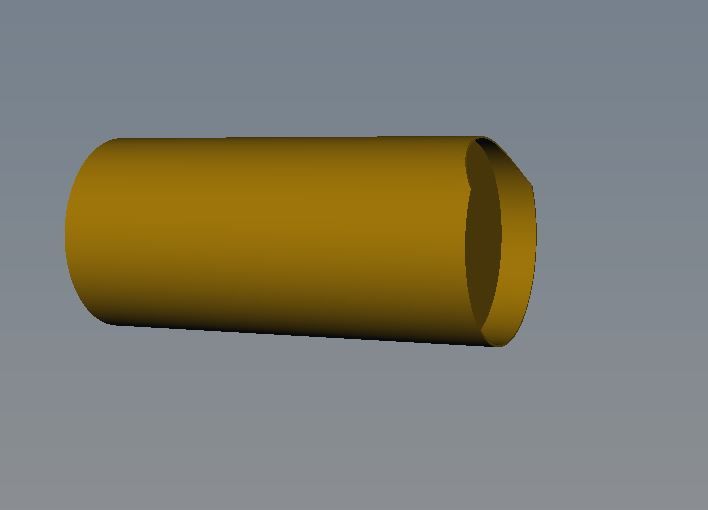

Ian looking at this 3D "sketch" the wall thickness around the outside looks to be very thin, assuming that a similar thickness of metal was left to the right of the parting cut then the metal may have deformed rather than the blade deflect. Also in the photo it looks quite a dark yellow metal so could be a bronze rather than brass or at least a softer grade brass.

I never thought of a CAD rendered image as being a sketch but I now see what you are referring to.

As I wrote a (few posts back) this thread could run and run. Most, if not all of the twenty or so replies are speculation and until the OP resurfaces they will continue to be so. The OP might have a valid reason for not getting back but another possibility is that its just a wind up!

If it a hoax (We have had them here before) then at least its exercised our brains even if its is a waste of good time!

My apologies to the OP if its just a poorly worded topic and the absence is genuine.

Ian P

jason udall.