The moment of truth finally arrived, so I ventured out to the garage wearing my best rubber underpants. Who knew what could happen?

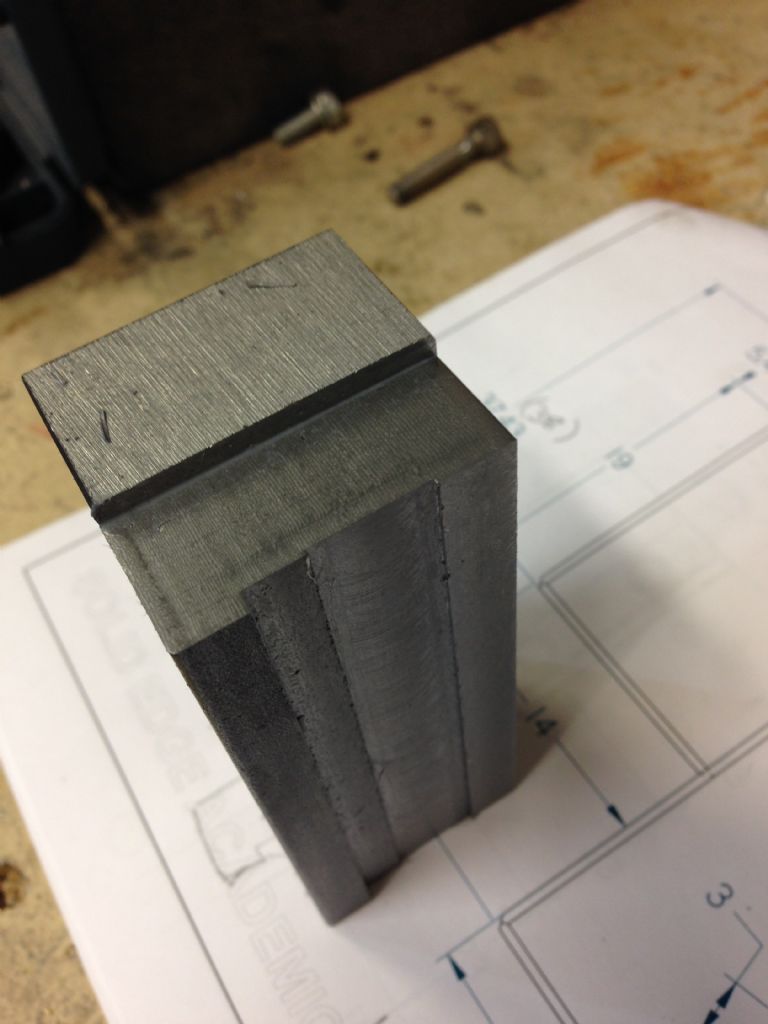

The first attempt wasn't entirely fulfilling. I pussyfooted about with what I calculated to be 2.3 thou per rev and about 400rpm with no coolant. I also discovered later that I was the best part of 10 thou below centre height. This resulted in several noisy but successful partings – but the surface finish was pretty nasty (little bits seemed to be welded to the bar surface) and there were some nasty grumbling noises going on. Not good. This didn't feel like the experience I'd been hoping for.

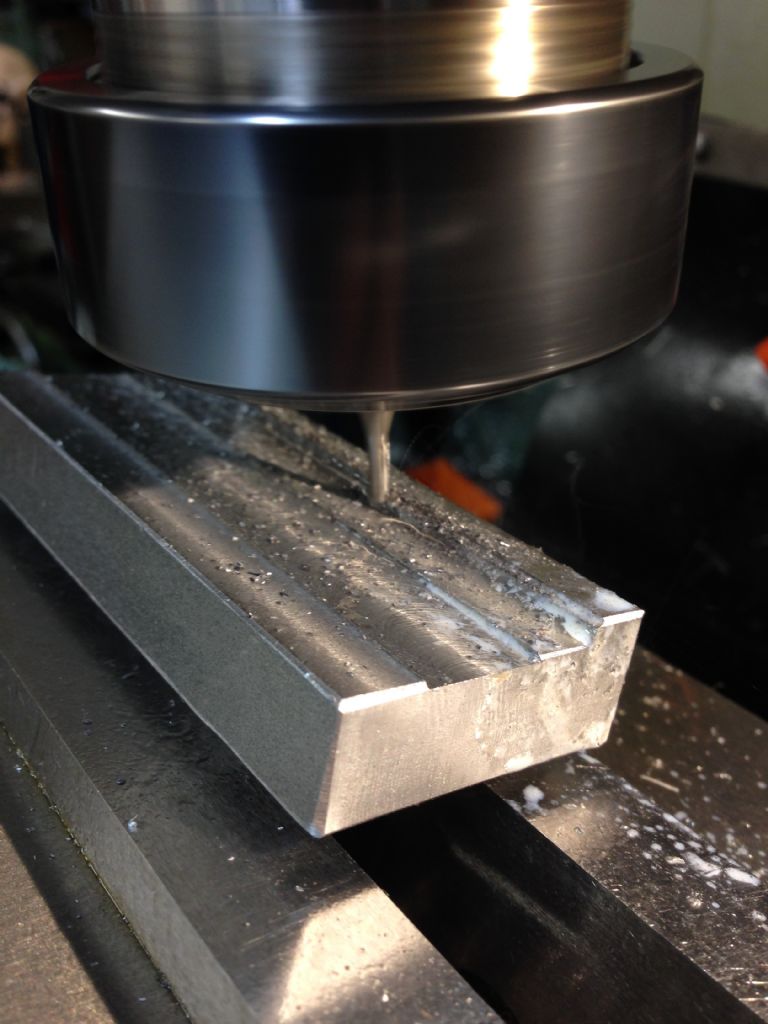

So after some researching and thinking and advice, I changed tactics. I checked everything was nicely nipped up, the tool was centred over the cross slide and a couple of thou above centre height and went for 5 thou per rev and 500rpm with flooded coolant, stopping half way in and upping the speed to 1000rpm (this was a 1" dia mild steel bar). Excellent result – no chatter or judder, nice clean surface finish, "approved" swarf and no nasty grumbling or snatching. Callooh, callay!

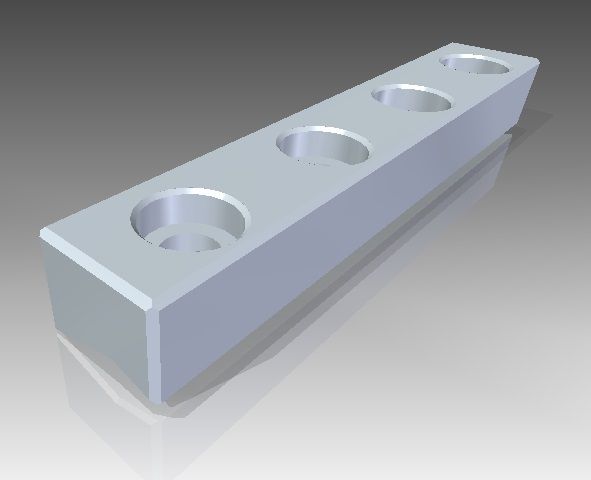

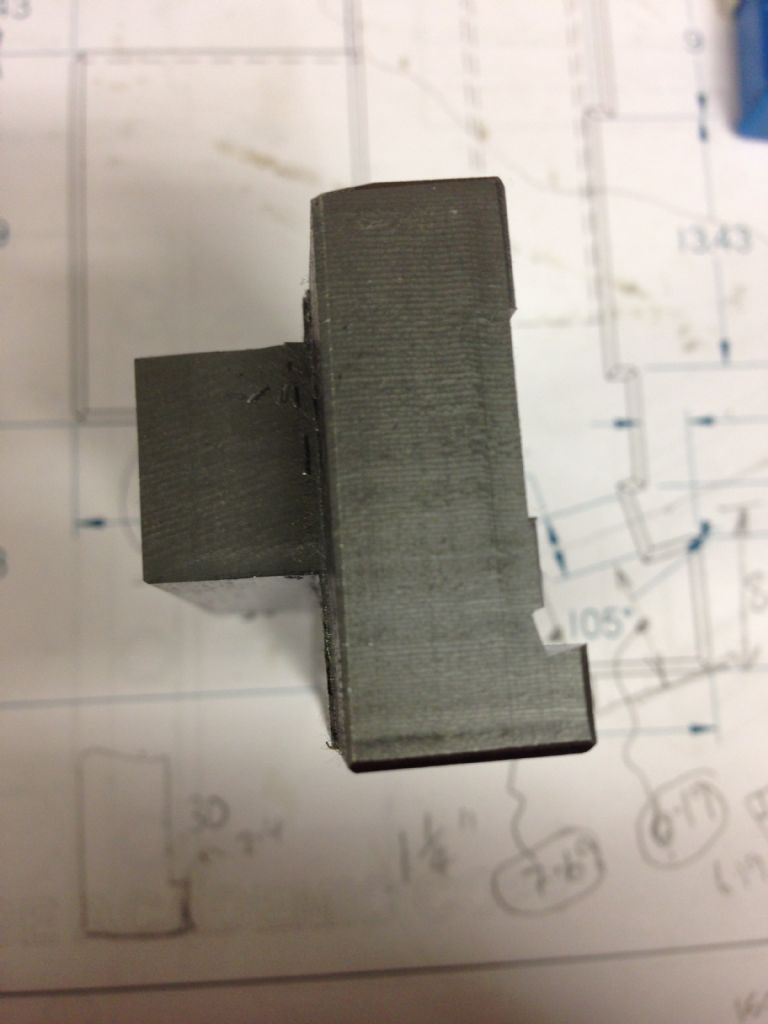

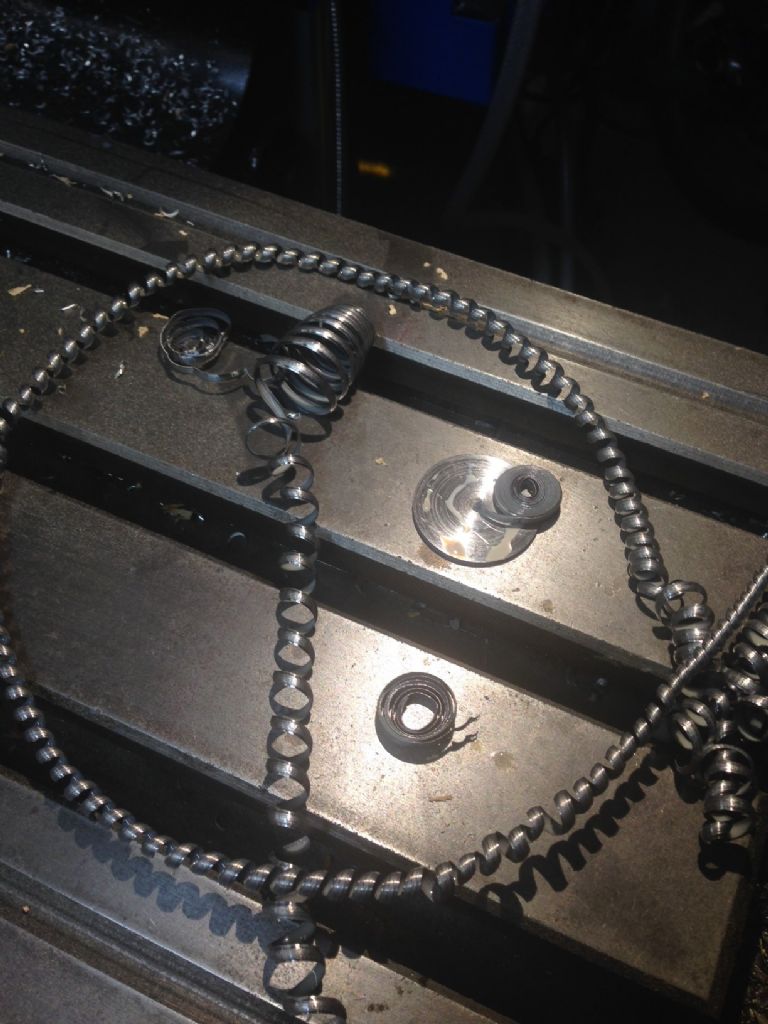

The last photo shows a whole parting event in swarf. Started out as a long, tight spiral, then progressed to longer curls as the groove deepened, then ended up with a series of watch springs that were generated within the groove. A bit unnerving watching these build up before finally coming free but the swarf is narrower than the groove due to the design of the chip breaker so isn't likely(?!) to jam. I found the swarf to be typically about 7-8 thou narrower than the 3mm nominal tool insert.

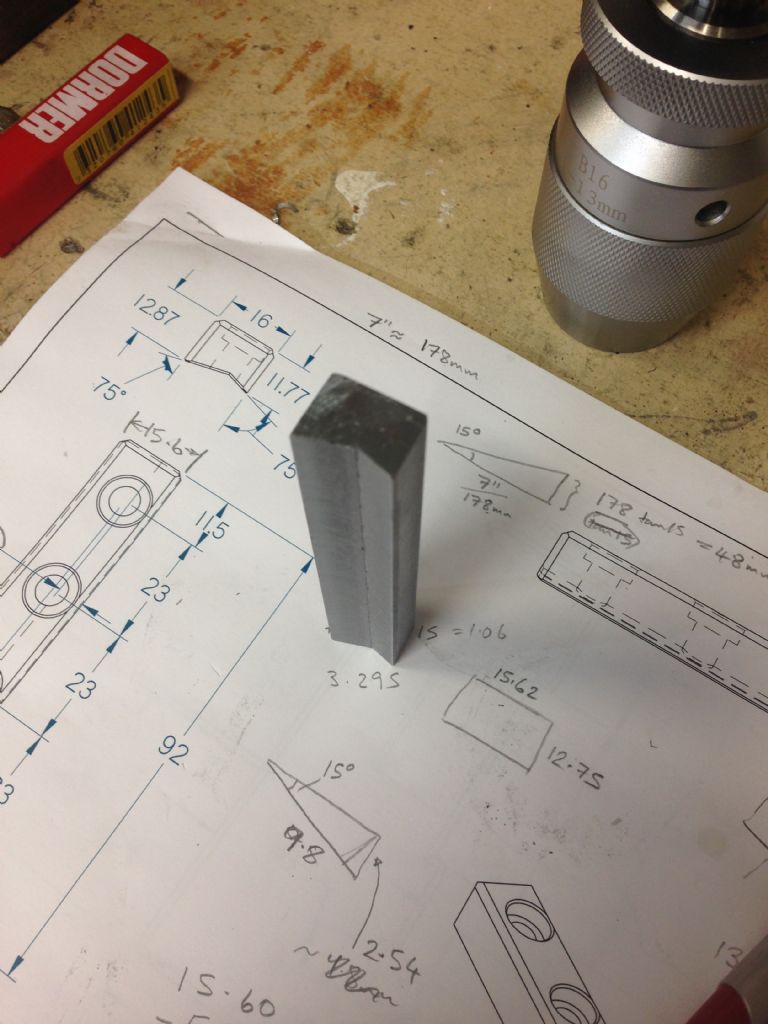

Its probably a bit early to start believing this is the end of the story but it seems to vindicate the idea that you need to steel(!) yourself and go all in with the recommended feeds and speeds. In the interests of science and a more predictable outcome in future events, I should explore the limits of chatter-free operation. It seems that there are typically regions of instability where combinations of feed rate and cutting speed result in chatter. This will depend on my machine as well as the dimensions and material of the workpiece.

Merry

Anonymous.