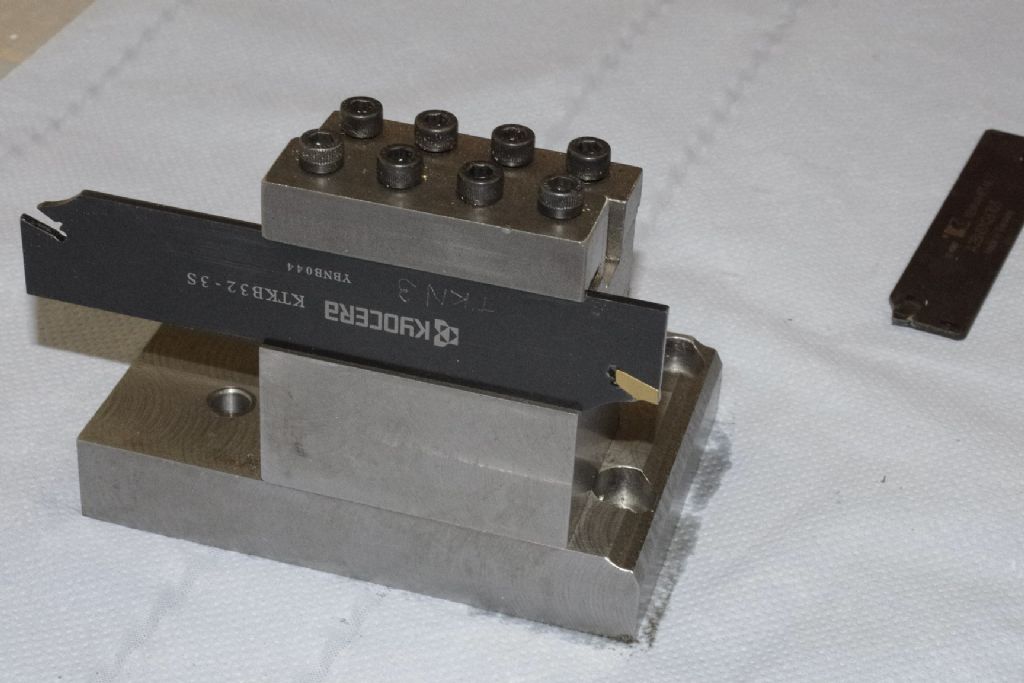

Nothing to do with parting PB but maybe as of interest, I have just parted this last week a 5" noggin of mild steel in a Colchester Student to make the 90T bull-wheel for the Parkes gear hob backing off device with no problem at all. No digging-in, no breakages and a tool protruding 2.5" from the tool holder, although I let it out in stages. This is not the first time I have done this as I have parted various large noggins previously to make back-plates for the Myford. The tool holder is the J&S type that holds an Eclipse type of blade, used straight off the grinding wheel, and held in an home-made rear tool-post as near a copy of the OEM accessory as I could manage.

Can't speak for PB but my method of parting these large noggins, and for all other parting in steel, is moderate speed (increased as the diameter decreases) and lashings of coolant pumped on, not dabbed or squirted, and a good cut that should not be interrupted once it has started. Aim for a nice 'hiss' and a ribbon or ringlets of swarf. I have used the power cross-feed before but not on this last occasion. The noggin was held as tight as possible in the 4-jaw independent chuck as I believe, or have been told at least, that four-jaws hold work more securely than 3-jaw scroll chucks and if I ever see a hacksaw near a lathe, I reach for my revolver, LOL!

Mike Hurley.