Posted by Martin of Wick on 06/02/2021 09:26:36:

…

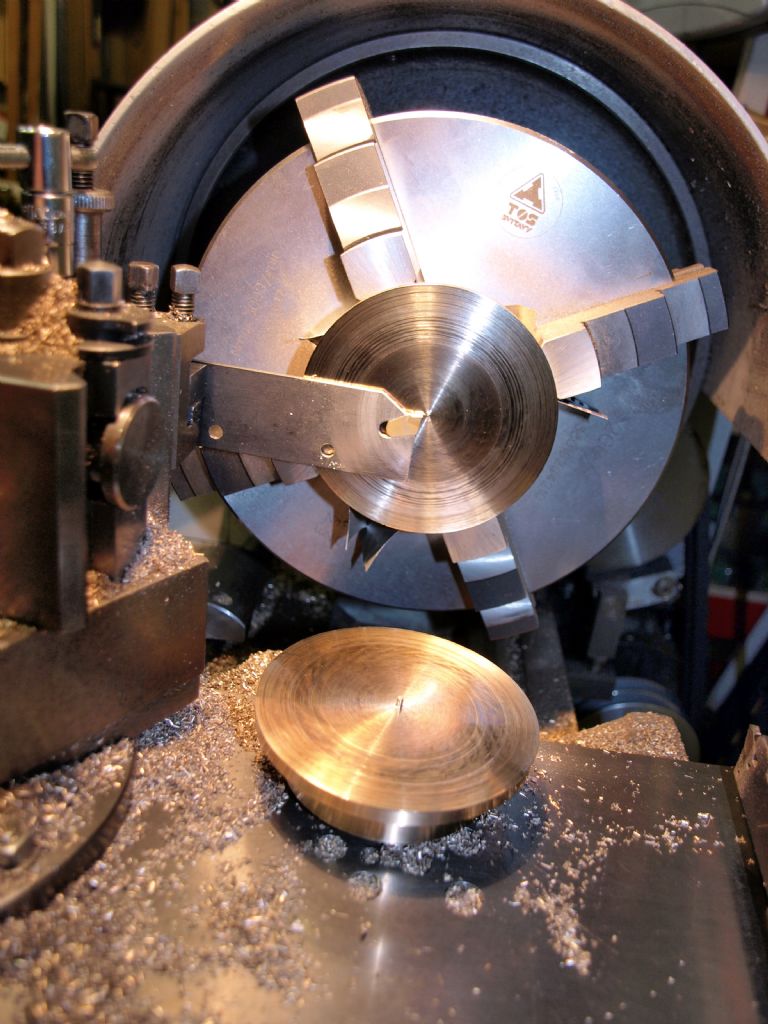

It just seems strange the HSS parting blade set up that was performing flawlessly with steel and silver steel moments before, completely balked at the bronze.

…

Probably not strange at all. We often generalise about alloys, perhaps assuming here that all Bronzes are the same. They're not! Alloys are formulated to emphasise a particular property such as toughness, malleability, ductility, hardness, springiness or – maybe – machinability.

Most Phosphor Bronzes are more than averagely difficult to machine, and some downright nasty; hard, tough and springy. A few Phosphor Bronzes are formulated to improve machinability, typically by adding a dash of Lead, but do you have one of these? What sort of PB is it?

My guess is the Super 7 is struggling to part an uncooperative bronze. All the usual parting problems are amplified by difficult materials. Insufficient rigidity and critical tool height. If the parting blade is too low, the work tends to climb and jamb the tool underneath, crunch, snap, gouge. If the parting blade is too high, it rubs, overheats, and work-hardens the job. Applying pressure to get a rubbing blade to cut is likely to end in tears too!

I'd hacksaw it.

Dave

Edited By SillyOldDuffer on 06/02/2021 11:47:05

Mike Hurley.