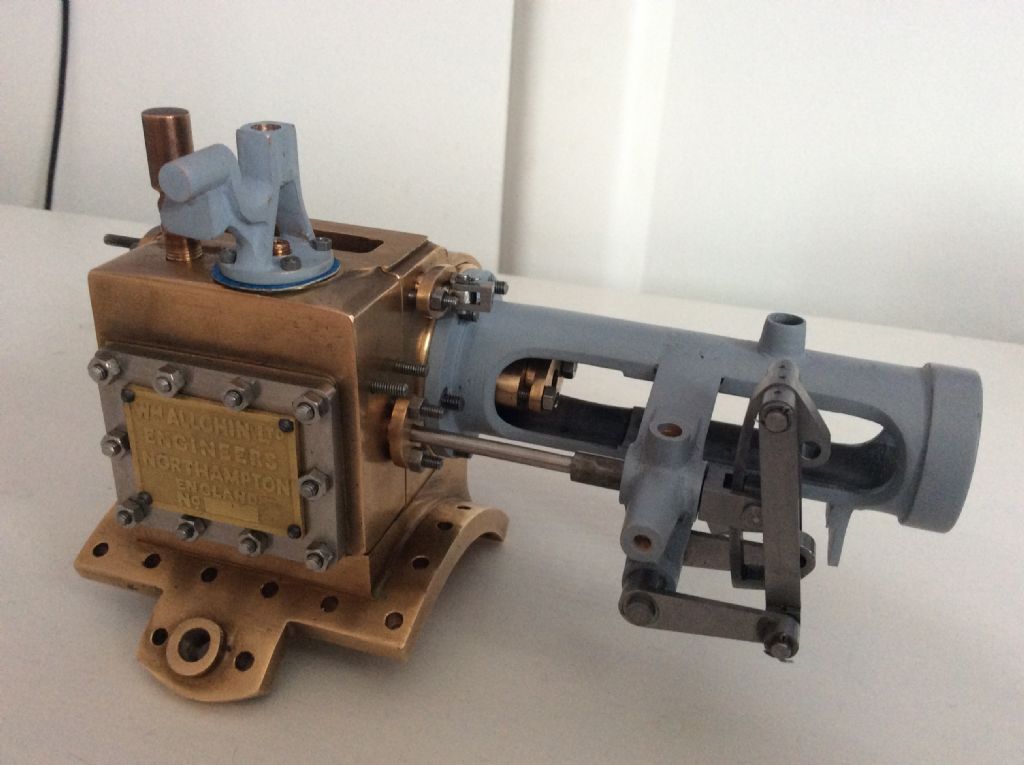

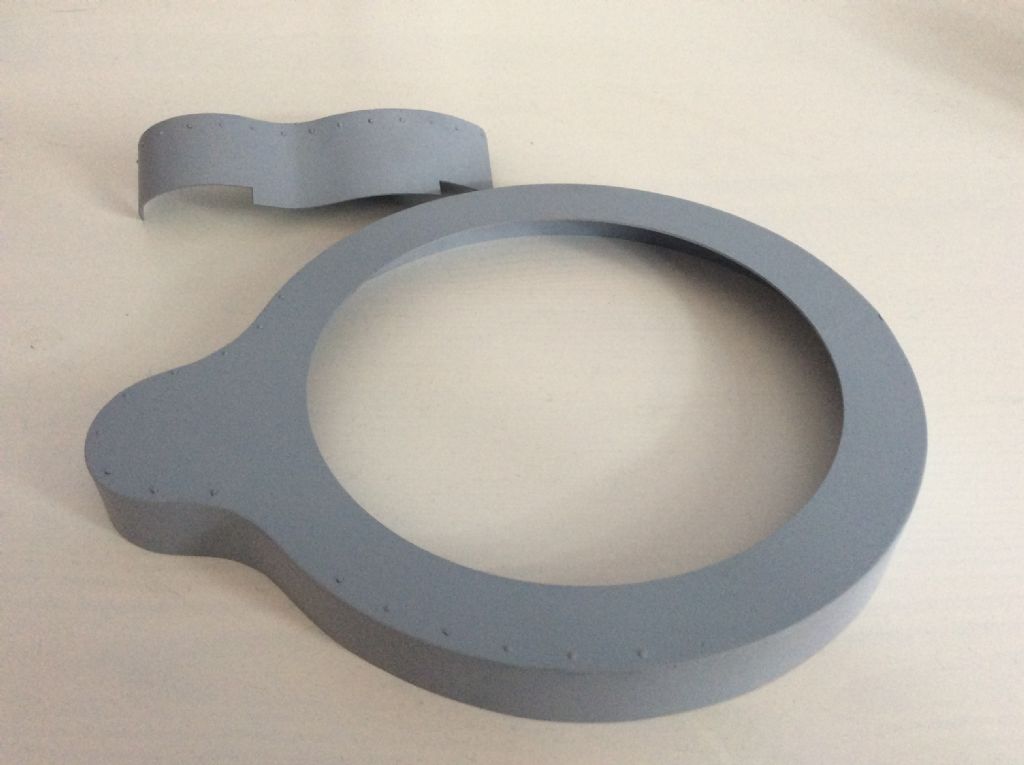

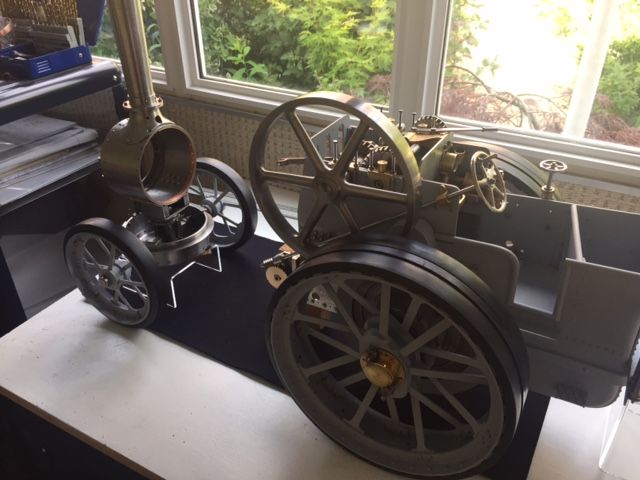

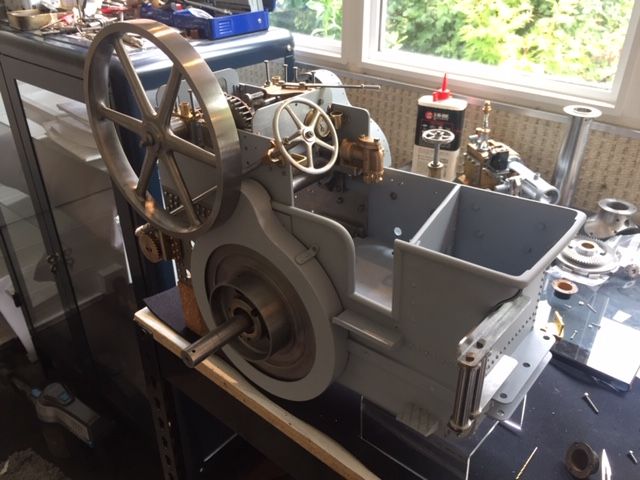

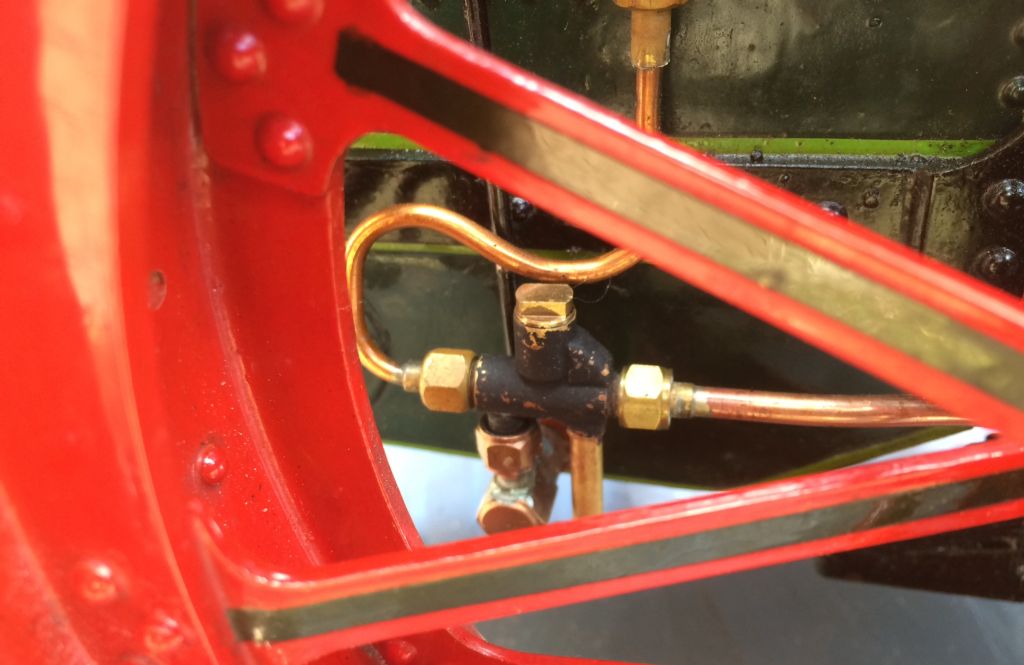

Part built Allchin 1.5 inch

Part built Allchin 1.5 inch

- This topic has 547 replies, 25 voices, and was last updated 10 June 2020 at 20:55 by

derek blake.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Solar panel lighting problem

- Lercanidipine

- VFD Article in May issue 351

- One for the electronics enthusiasts?

- Building Bernard Tekippe’s Precision Regulator

- What Did You Do Today 2025

- Motor to lead screw coupling method

- Generator size for vfd controlled 3 phase 5.5 kw motor

- Stuart Twin Victoria (Princess Royal) Mill Engine

- Gas Engine Needle Valve