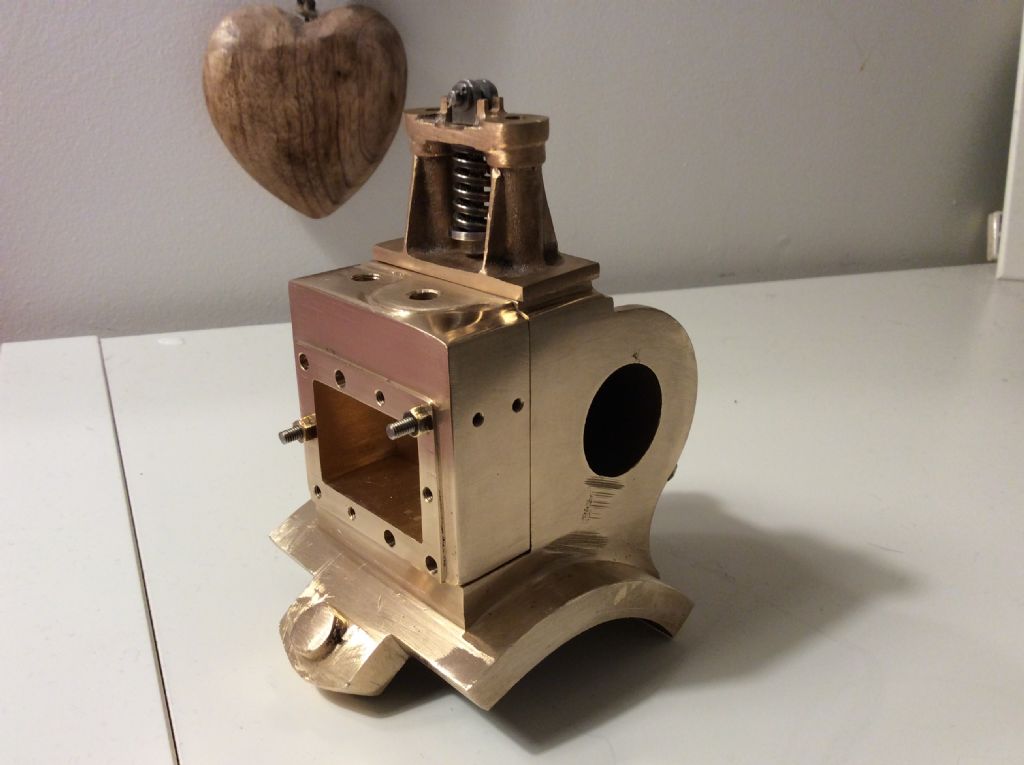

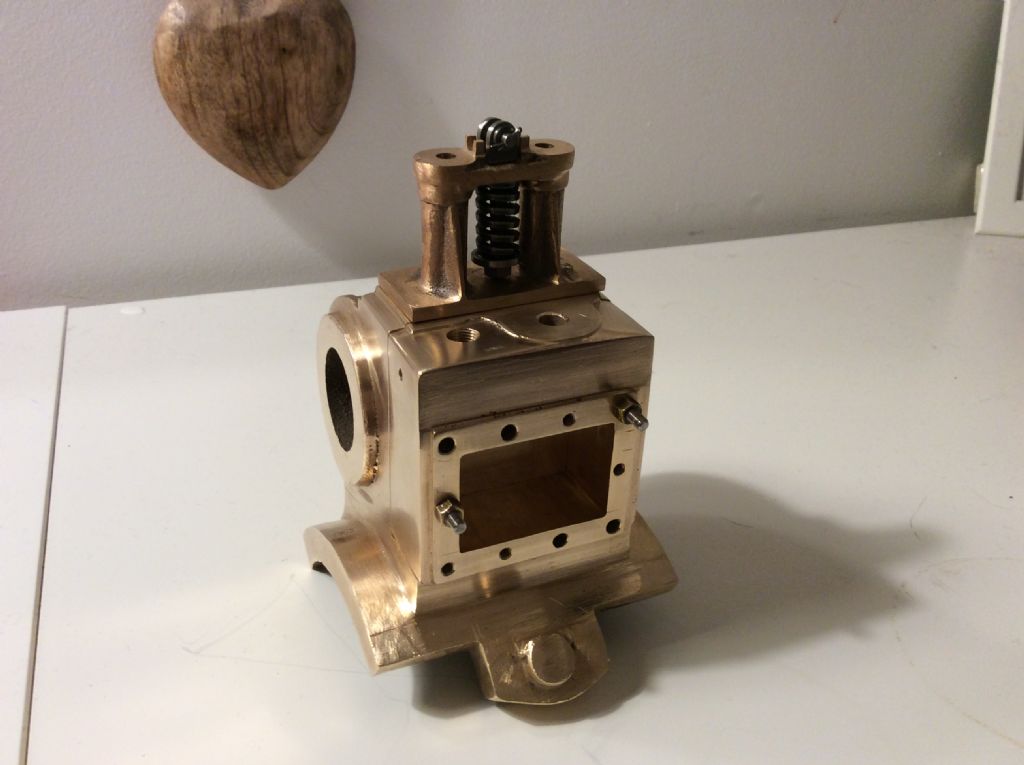

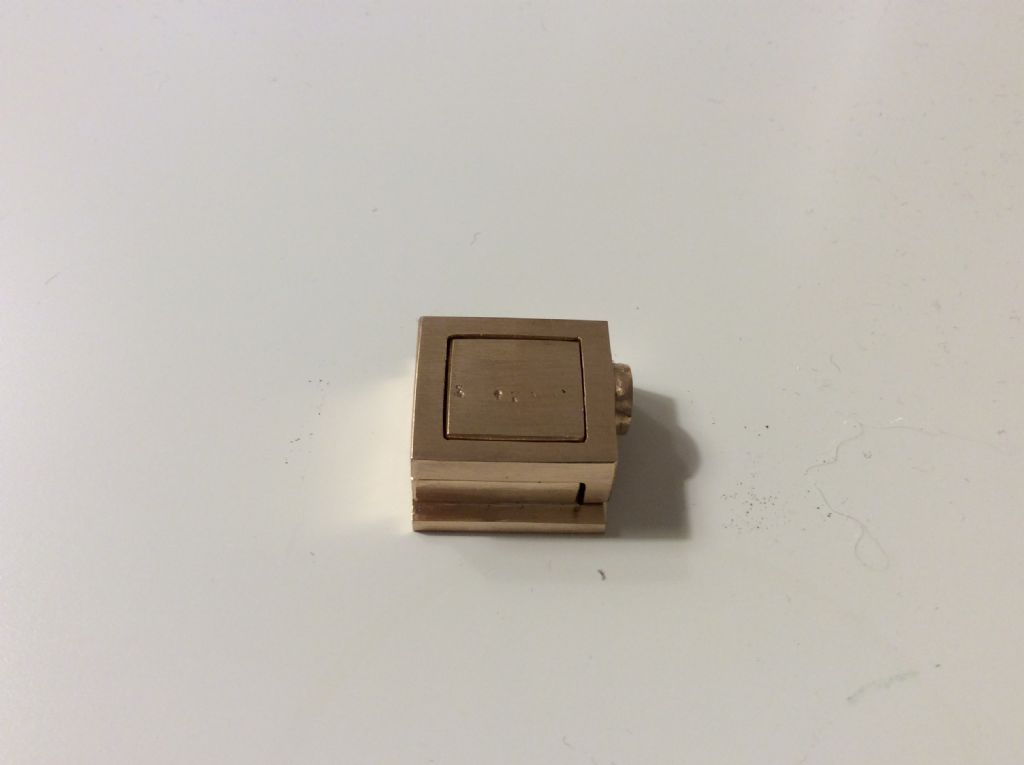

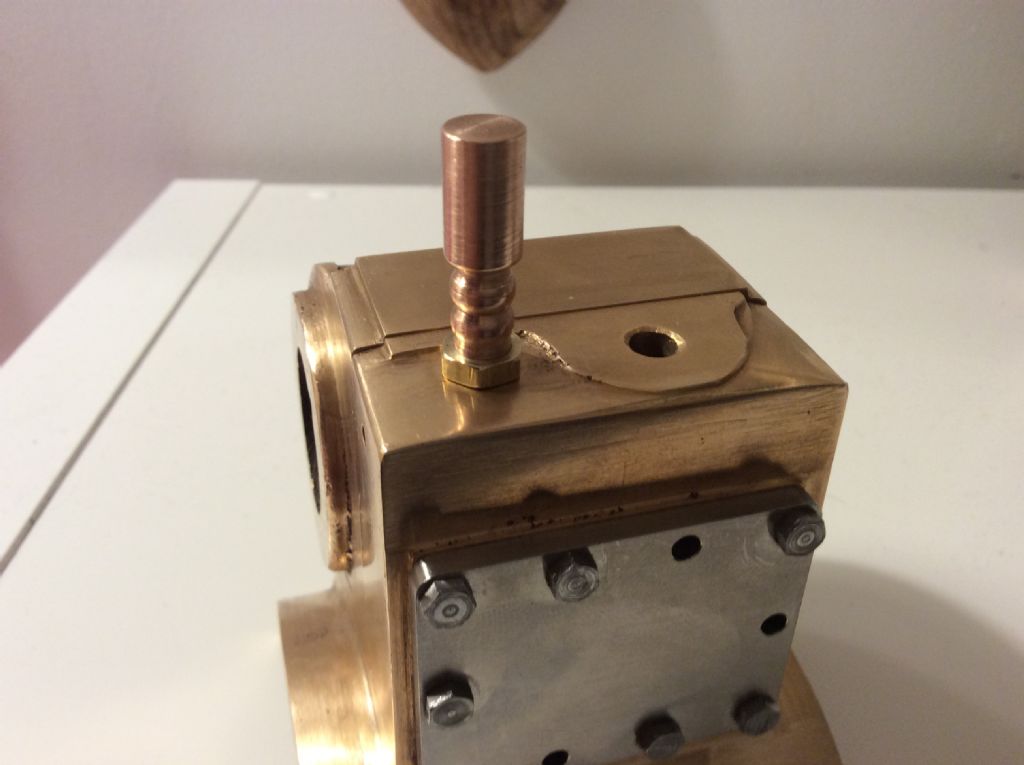

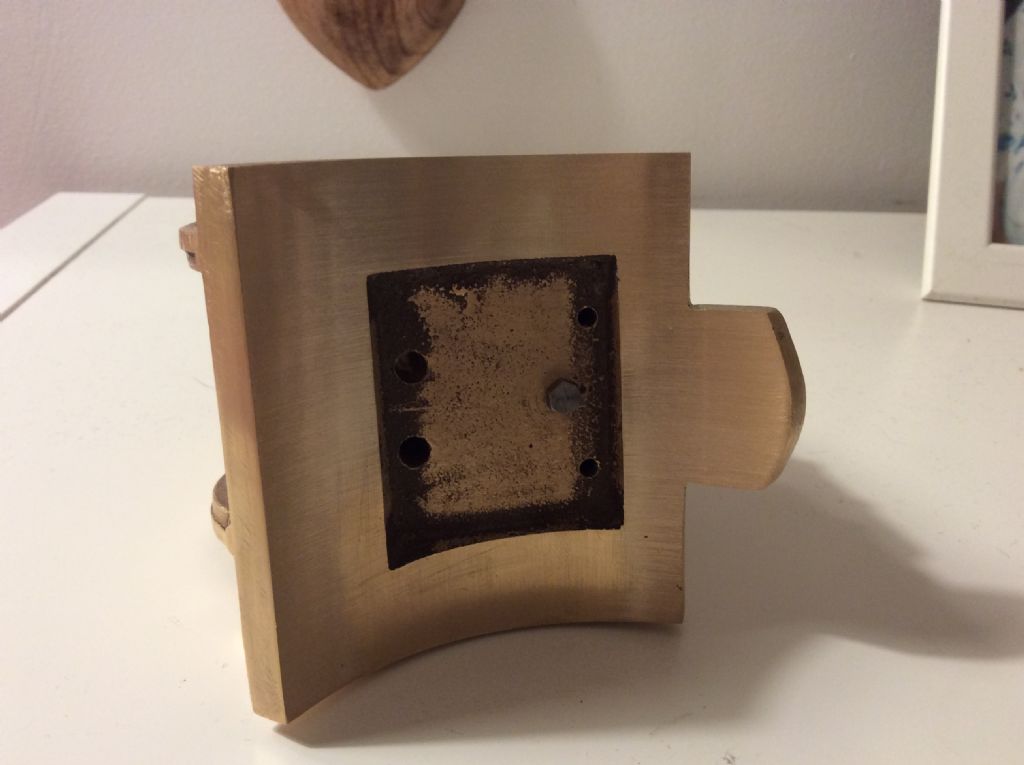

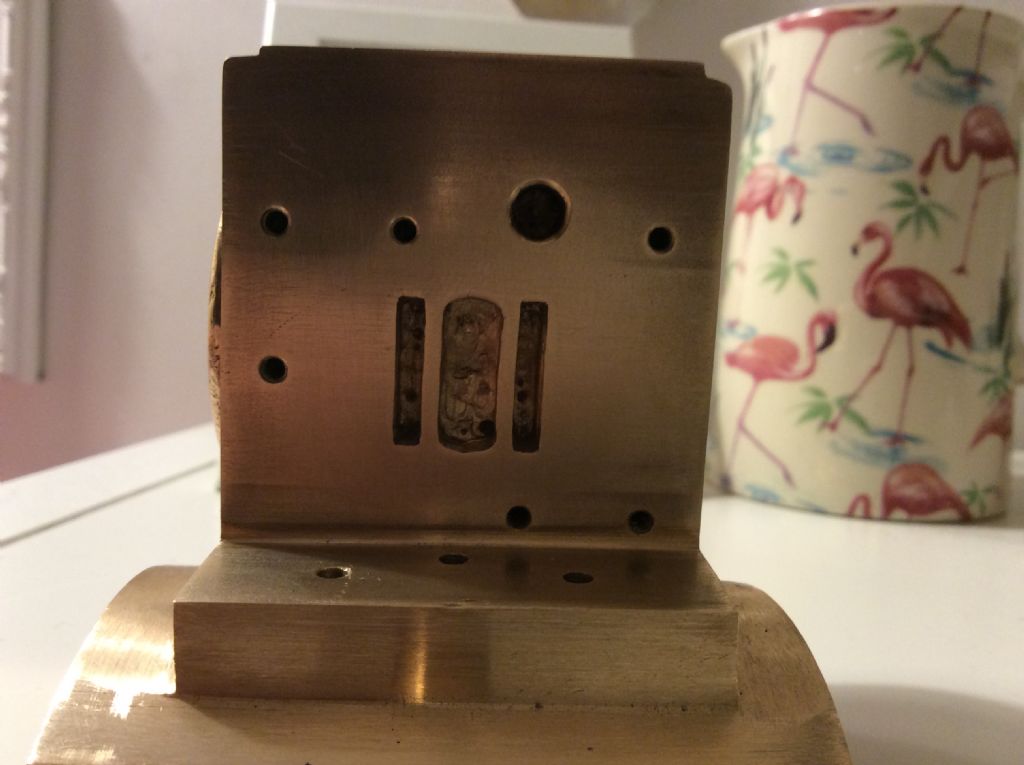

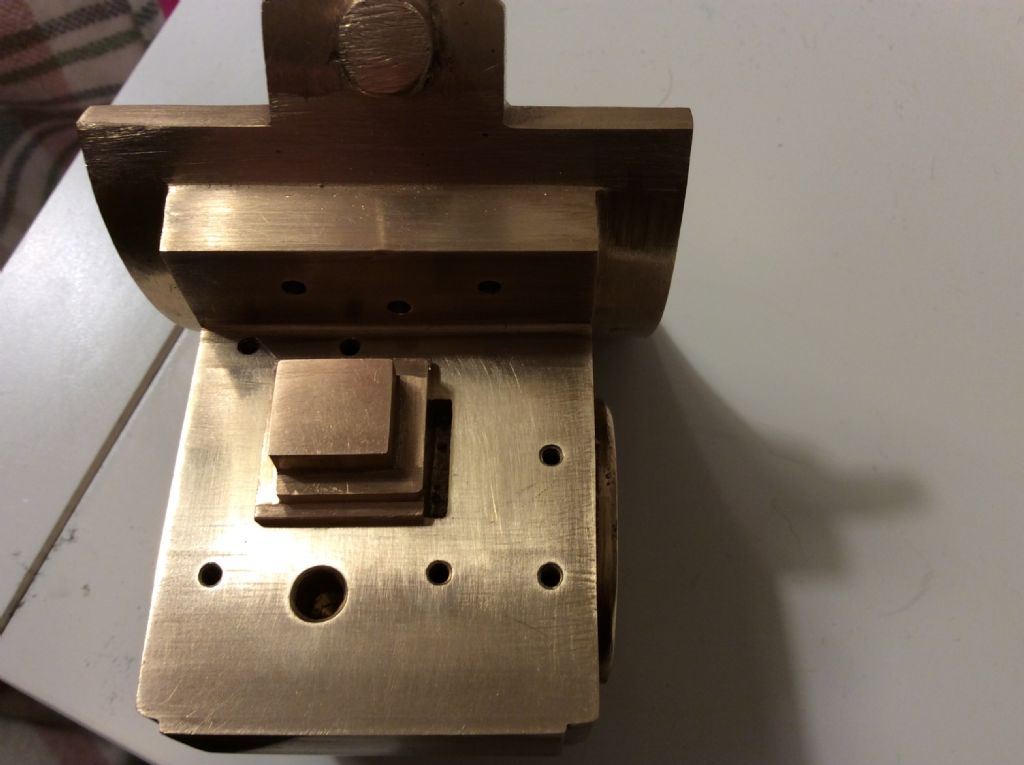

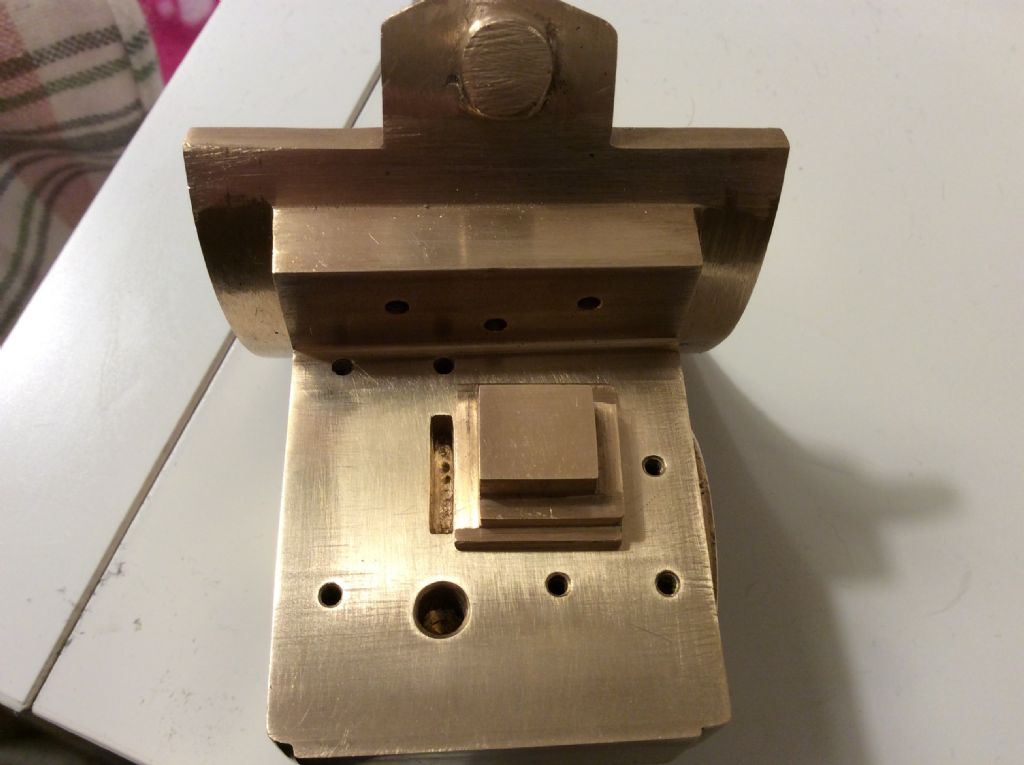

Part built Allchin 1.5 inch

Part built Allchin 1.5 inch

- This topic has 547 replies, 25 voices, and was last updated 10 June 2020 at 20:55 by

derek blake.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Sat nag

- Screw cutting 1.25mm pitch on a Colchester Student.

- Boiler Design – issue 4765

- TurboCAD – Alibre File Transfers.

- Indicators – vehicle

- buying machine tools from aliexpress experiences?

- Variable DC power supply?

- Silver steel crankshaft

- Another Day … Another ScumBag

- Adjustable spanner thread direction