Derek,

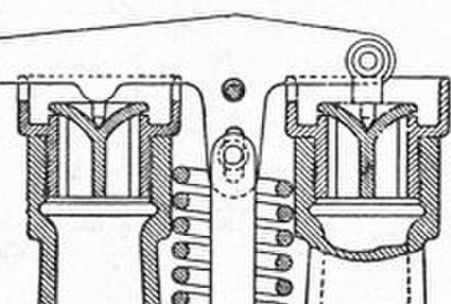

As Micheal says the point of effort for the spring bar needs to be below the line of contact with the valve and seat. One of the points on the bar as indicated in Micheals drawing also needs to pivot. You will not find a pair of these valves that both lift at exactly the same time so small degree of articulation is required. The set up shown is similar if not identical to a set from a Burrel I repaired for a friend. Adjustment was a nightmare as the adjusting nut was inside the steam cavity. I ended up making a false housing for the valve assembly to bolt on to and set them up on air for the lift pressure. Air does not behave the same as steam but in terms of the actual pressure to get them to lift is close enough, it's the re seating that will not be the same as the air does not have the expansive property of steam. You say the fit of the valves in the body is "loose" what does loose actually mean? A couple of thou clearance, 5 thou or 20 thou? They should not be a tight or even a close sliding fit at normal temperature as you need to allow for some expansion, the last thing you want is for them to bind when they get hot and jam shut! Conversely they don't want to be so slack that you can throw them in from the other side of the room? Loose is a relative term here!

As Micheal also says the width of the seat wants to be fairly narrow I am not sure of the relative size of these parts but I would say 25thou contact would be more than plenty. If the body were machined to a sharp corner and then lapped in with fine time saver the resulting bevel of the seat should be plenty.

I would suggest for a start you make a dummy housing with an air connection, get a bit of weight on the spring (having lowered the point of contact for the bar by removing the solder) and see what happens and at what point they lift -! You need a decent gauge in the system! If it's any consolation this type of valve in miniature are really hard to set up and get working right, that's why lots of people hide a pop type valve inside a dummy representation! Also at the moment if they leak like a sieve they are as safe as you can be because you will never build up any pressure in your boiler under steam!

I am afraid this is a case of patience and perseverance and unlikely to be solved purely by having two new valves made. You will get there.

Paul.

derek blake.