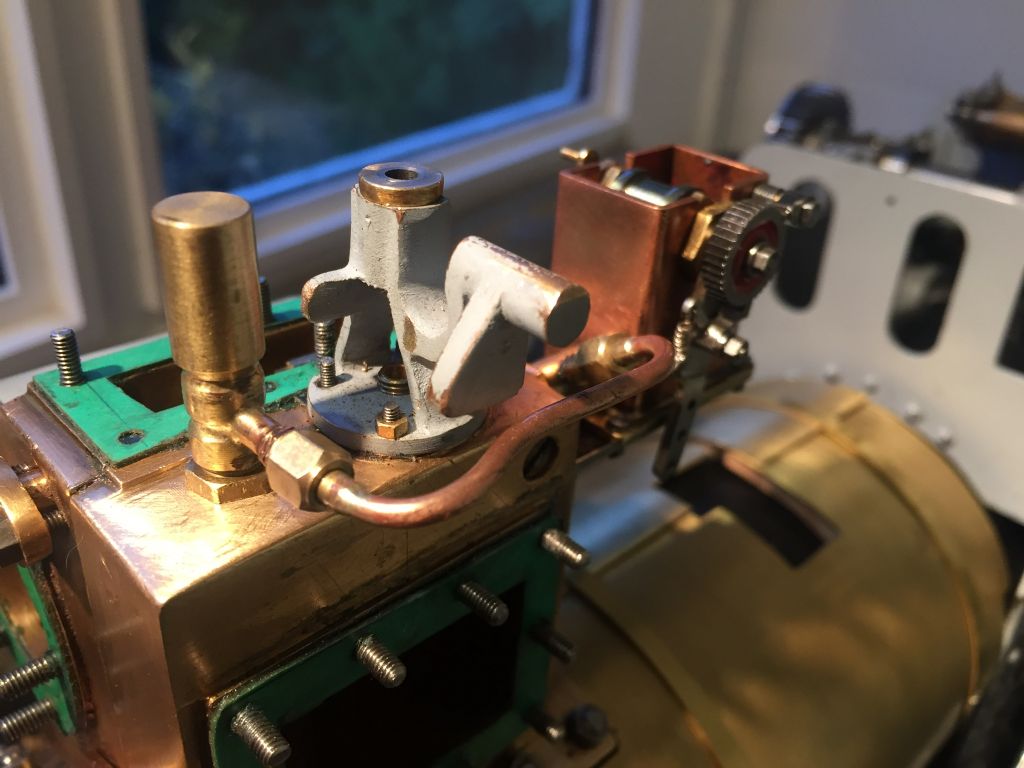

So I was unsure if I had sealed the exhaust blanking plug well enough so to make sure I was OK, I removed the cylinder this week.

i was scared to death it would cause issues but I was lucky and it removed well, while it was off I replaced the three bronze studs and changed them for stainless as per the other fixings.

blanking plug was hard to remove so I think it was actually ok, but I added new steam seal loctite and covered the hole with Jb weld just to be 100% sure.

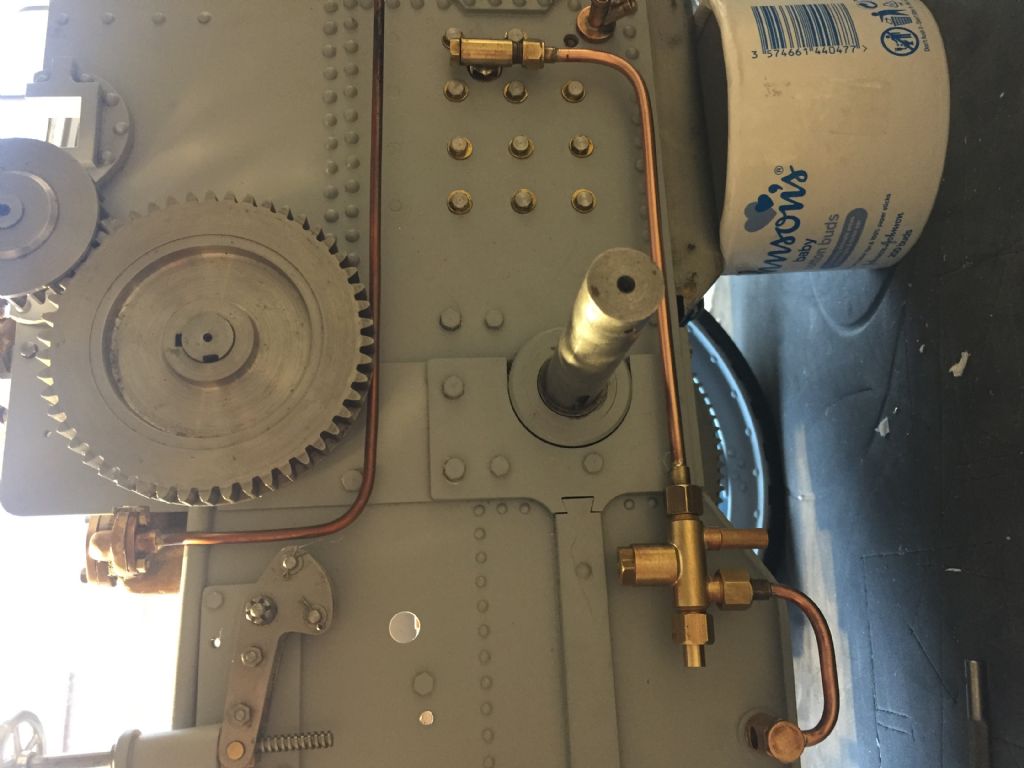

cylinder refitted this evening, what I’m struggling with is the oil lubricator the pipe as per drawing is tiny so is this the correct pipe? I’m also struggling to make the fixings as well as actually getting the oil to enter the cylinder.

i think it’s to do with the ball and spring which maybe too strong, so I’m going to have to start fresh and make a new parts and try again.

has anyone any info on pipe size or how to make the fixings for these pipe ends as I’m assuming you can’t buy bits that small.

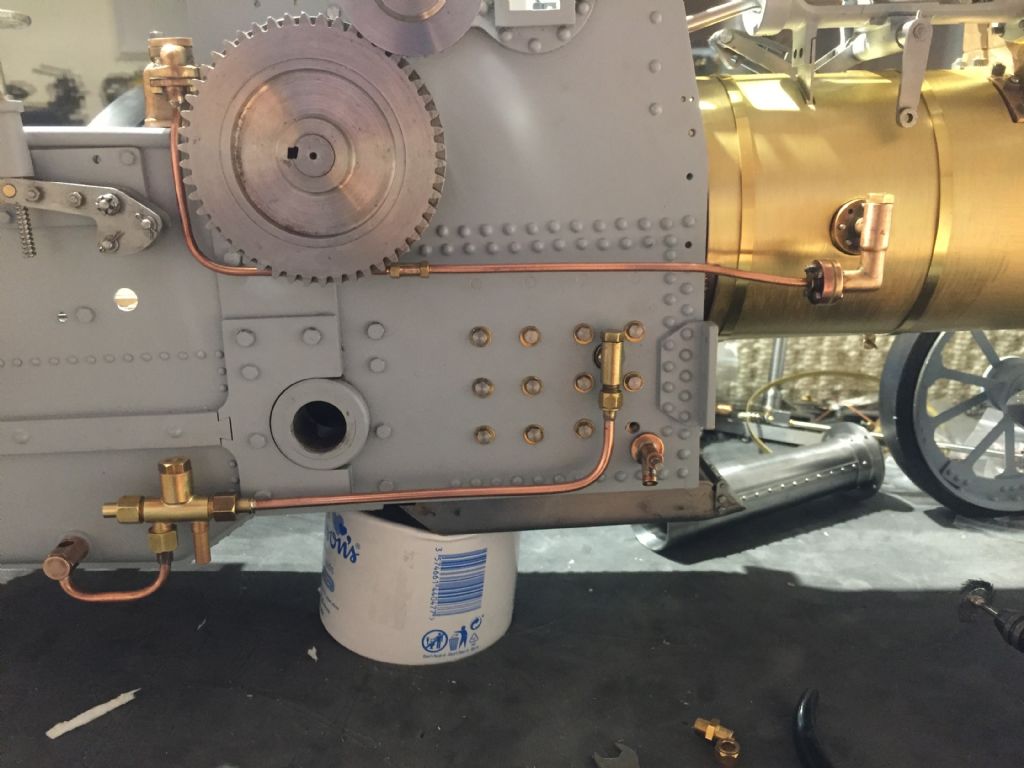

i appreciate explaining in a message is difficult so no problem if no comeback on the questions, weekend work involves finishing pipe for the steam valve to injector which I’ve positioned next to the pump.

i couldn’t find the correct size valve for pipe so this position should be fine for now, it’s not to drawing of course but I’m more for making a working engine over a 100% to real engine model.

as I become more skilled I hope to make these valves in the future….

derek blake.