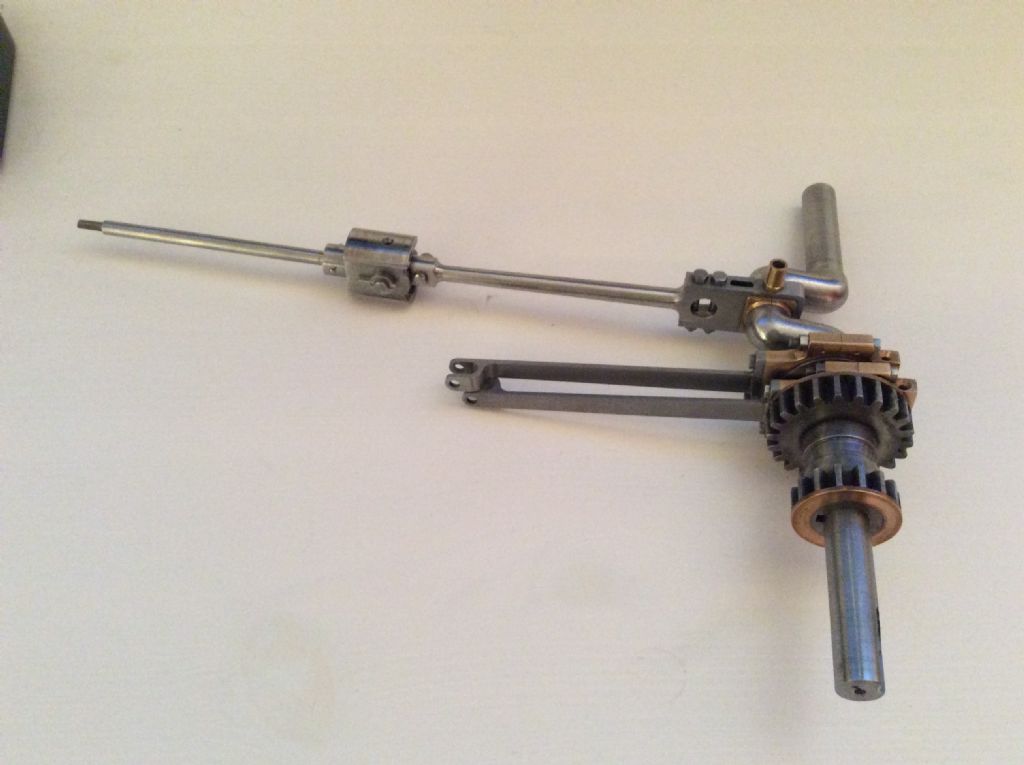

I built an Allchin years ago, and over an extended period. I found the drawings good but Hughes' 2nd construction series in ME, which began well after I'd made a start, was very useful, especially for some of the "fiddly" small detail. This, for example, would include the water lifter and hose, but also plenty of other bits and pieces. I'd strongly recommend looking for this series, or the book.

In that series, he acknowledged that the original lubricator design couldn't be assembled, but I think that was the only significant drawing error.

During my build, the valve gear was criticised by, IIRC, John Haining in ME. Based on Haining's undoubted expertise, I re-made the eccentrics at that time, it must have been change of throw, but I no longer have the details. My Allchin seems to run OK, but, TBH, I suspect that so do many others that are made to the original dimensions.

The design makes for a very nice looking model, but not the easiest one to build or operate IMHO.

Clive

Edited By Clive Brown 1 on 06/12/2018 09:16:06

derek blake.