john's excellent modification deals with one of the problems but there remain others.

there are 2 types of problems; geometric, and practical/mechanical.

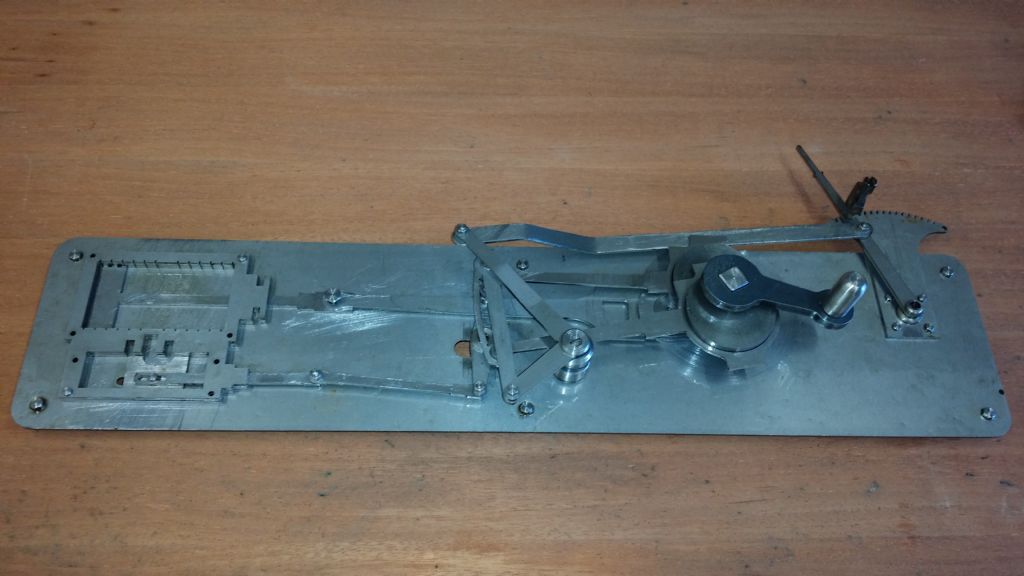

of the practical/mechanical, parts of the valve gear are far too flimsy and wear badly and cause lost motion. the single rocker arm bearing and top lifting link pin for the expansion link are culprits. valve setting is compromised by the difficulty of adjusting the valves by altering the position of the rocker arm. some easy modifications and improvements can solve these problems.

geometrically LBSC (and Don Young) drew all their loco link stephensons gear out incorrectly. i wont go into the details here other than to say that the radius of the expansion links is wrong, and the position of the rocker arm pivot and weighshaft are critical to provide acceptable valve events and need altering. the position of the weighshaft isnt even dimensioned on the drawings (though is stated in the ME construction notes, not that LBSC got it it quite right). other minor improvements can be incorporated by providing Don Ashton's 'corrected lengths' for the eccentric rod centres to give equal leads, and modifying the usual valve setting proceedure and removing the exhaust clearance on the valves.

instead of a PANSY that will only run in forward gear (still with lumpy cut offs and exhaust events) you should be able to have a loco that can be notched up to 25-30% in forward and reverse. anyway mine does!

there are lots of errors and bad design features in the original drawings that catch out the unwary on the rest of the loco. of these the boiler barrel being too short and the wet header interfering with the petticoat pipe are perhaps the best known, as is the need to turn the front axle down to 5/8" dia between the axleboxes to avoid it hitting the bottom slidebars.

if anyone wants a full list and details i will happily send them.

cheers,

julian

james craig.