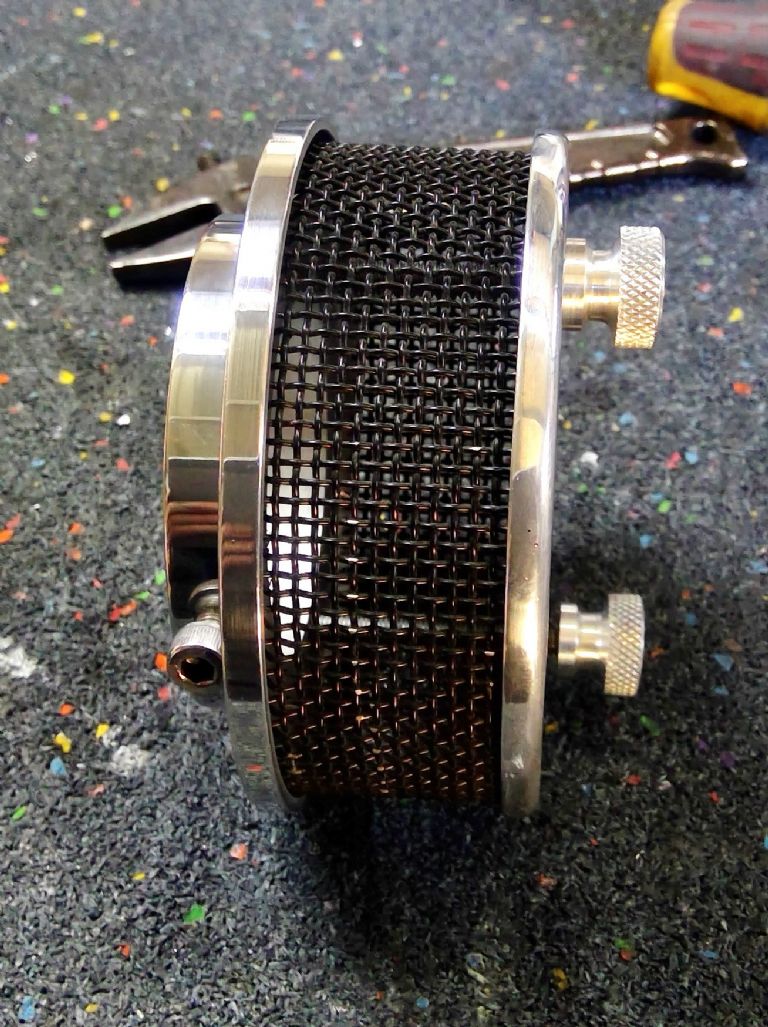

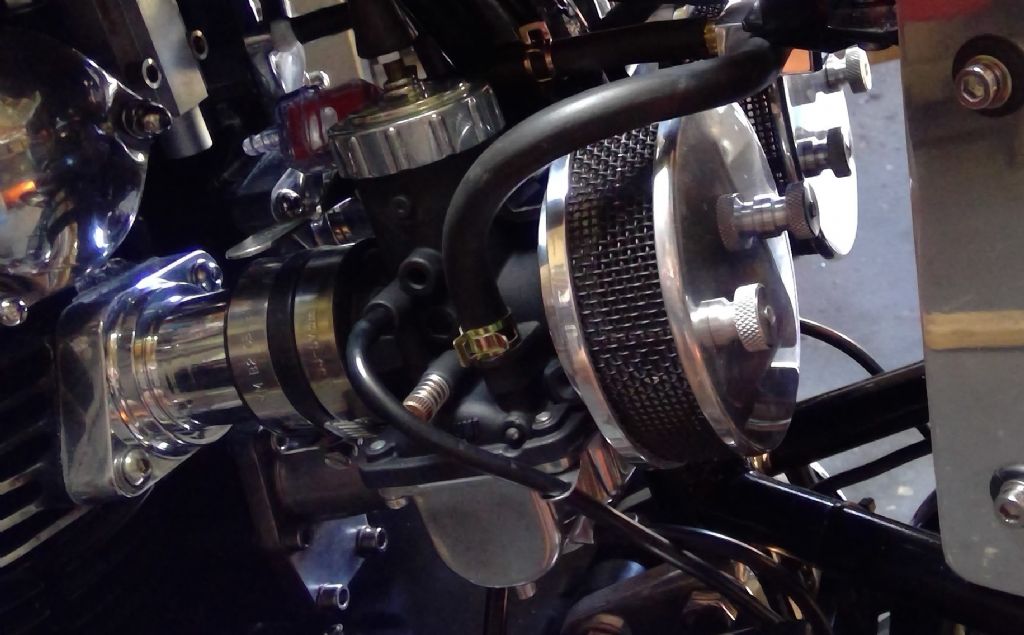

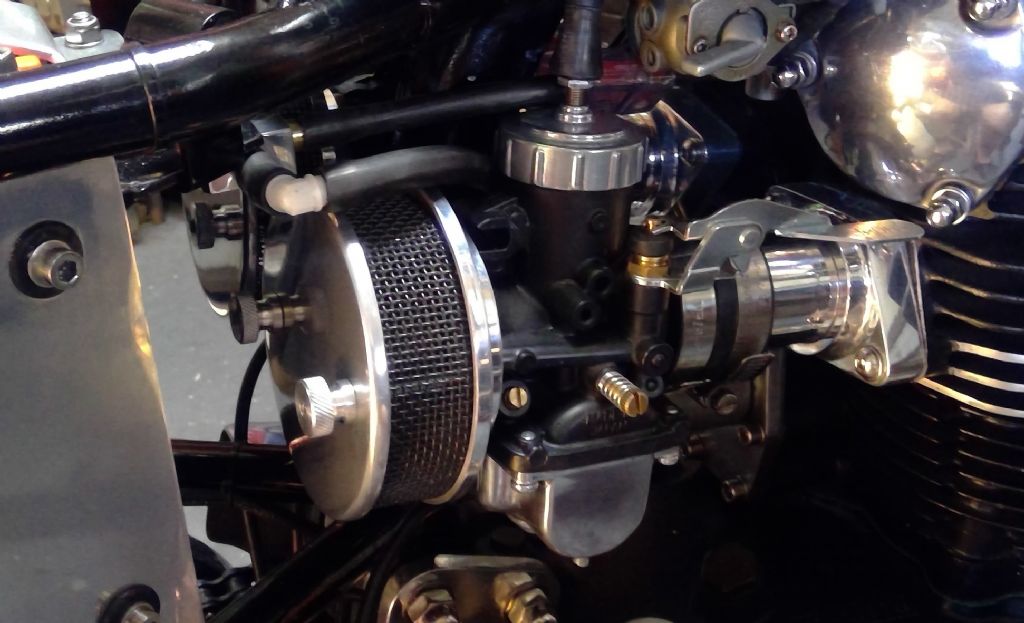

Pancake filters.

Pancake filters.

I took lots of pictures to outline the steps in making them.

I cut a 15mm slice off the 101.6mm lump of ally and turned down one end to 97.4mm, then cut a piece of 1.7mm sheet to around 111-mm in diameter, stuck them together and bashed the overhang until there wasn’t one. I have to use my left hand now, as the right elbow complains. Sounds easy, but it’s not, out of every 10 strikes, I think I miss about nine.

Once formed, I mounted it in the four jaw, and turned the overhang down to 3mm, then smoothed out all the scratches and what not with sand paper, finishing off with the random orbital sander with 240 grit.

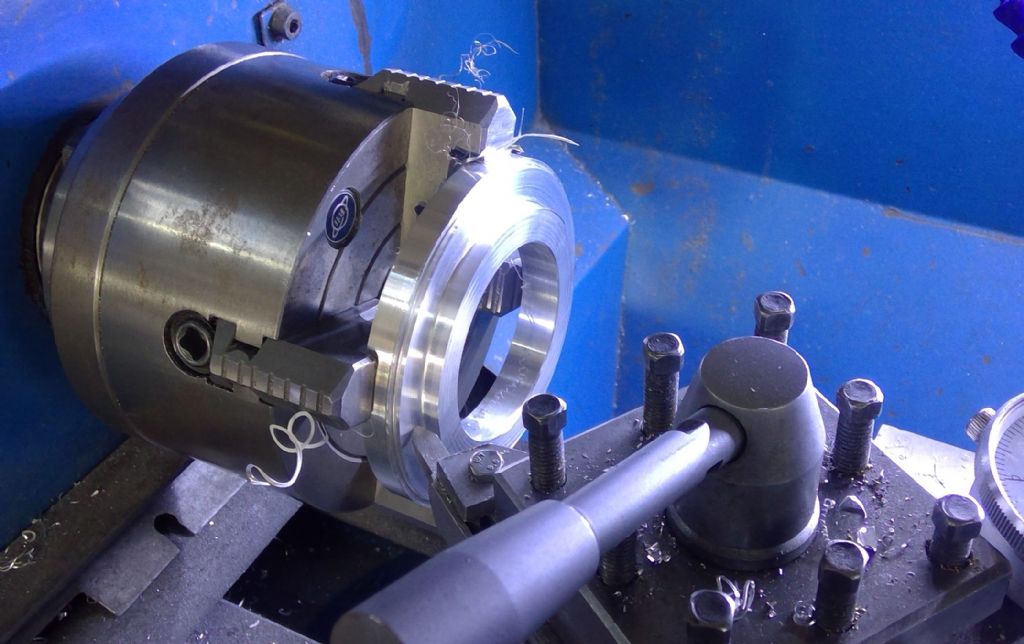

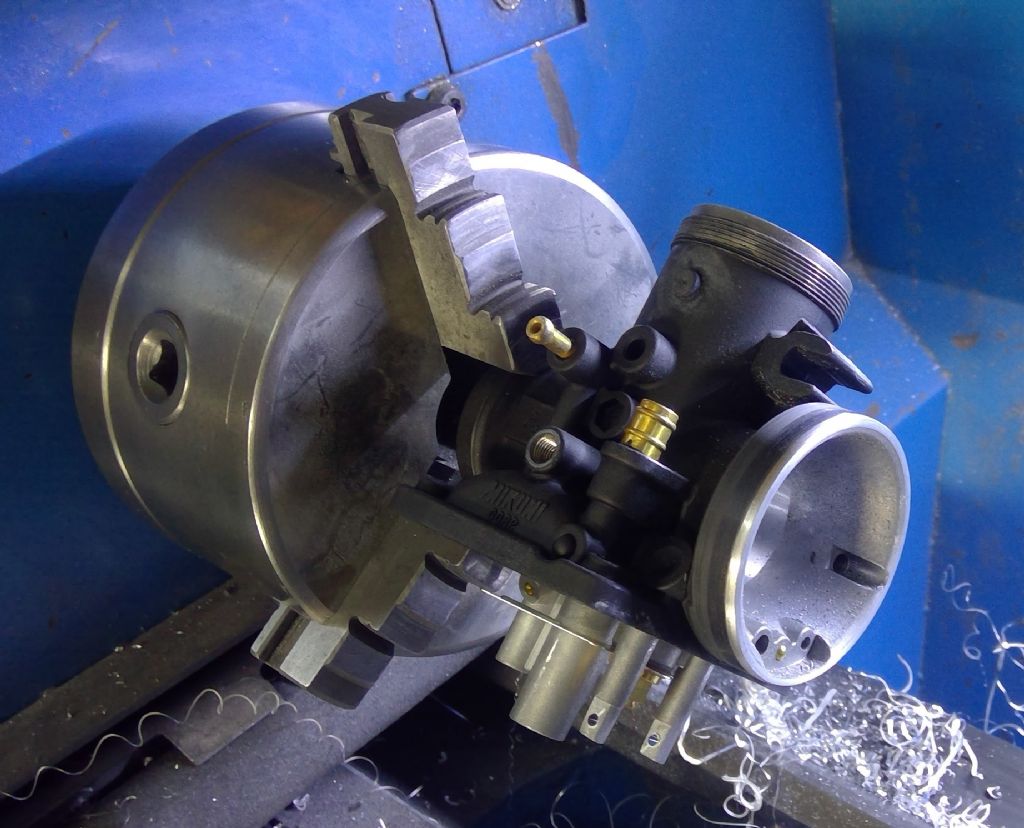

Next, I mounted the 15mm slab in the three jaw using the turned down area and drilled through with a 25mm bit, machined the outer diameter to 101.4mm, machined out the centre leaving a 2mm wide lip on the periphery, 3mm deep, then bored out the 25mm centre hole to 57.3mm to fit the 57.4 mm carb bell mouth. .10 mm proved a little tight, .07 would have been better I think.

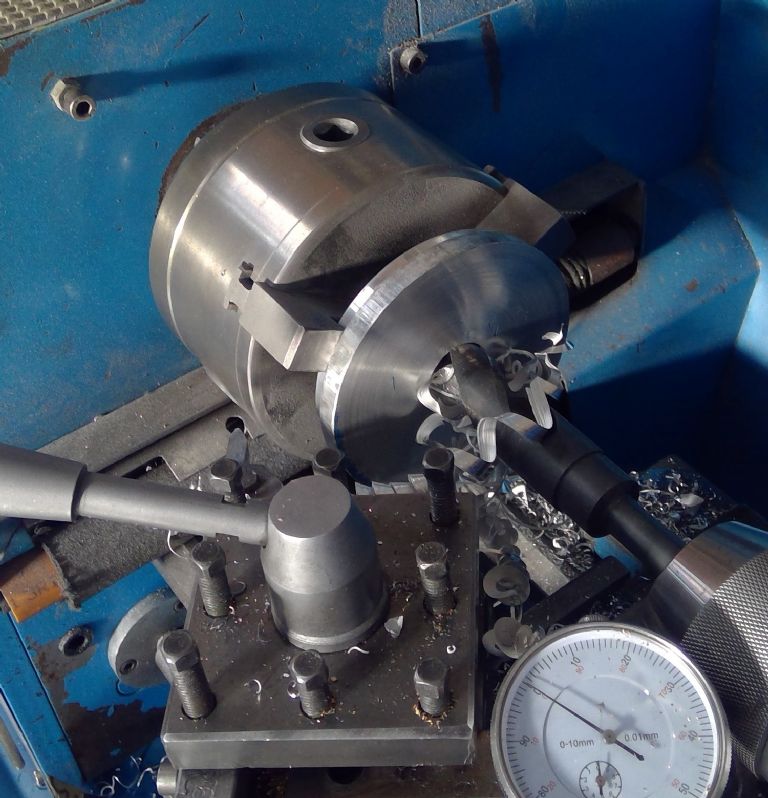

I flipped the slab over and mounted it in the four jaw, then spent a couple of hours trying to centre the damn thing, then turned down the inner mounting ring so its 8mm wide and the flat body of the filter 2mm thick. Final step, turn down the inner mounting ring so its 9.8mm deep.

The cutting tool was then centred., spot on, and used to scribe a line across the back of the centre mounting ring. After removing from the chuck I found the centre point using a calliper, centre popped it, mounted it on the mill and drilled the centre pops with a 4mm bit, then mounted it on the pedestal drill, centred the holes and tapped the 4mm holes with a 5mm x .8 tap. The plate was then turned on its side, and drilled and tapped in the centre of the centre ring at 90degrees to the other two holes on the face.

The piece was mounted in the three jaw again and using 240 grit any cutting ridges were smoothed over, then both plates were polished.

The knurled securing nuts were turned up from a piece of 20mm stock, tapped 5mm and then knurled using the scissor knurler. These were mostly done by eye, so won’t be absolutely identical. You’d need a calliper to pick up the difference though, so good are my four eyes.

The carb body was mounted in the three jaw and a file used to remove the ridge at the beginning of the bell mouth. The face of the bell mouth was pretty rough, so I took the time to smooth that with some emery. The turned piece was located over the bell mouth, the assembly was then stuck in the vice and pressed into place.

Nicholas Farr.

Nicholas Farr.