If that etch-in-a-can works, then that is a neat and 'clean' method for sure. But, I have yet to find such a solution actually providing a durable surface that has properly adhered. All the spray can 'solutions' and even the chromate etch primers that you can spray on or paint on with a brush, have solvents that evaporate very quickly, giving very little time for the etch to take place. Even industrially it is recommended that the aluminium is first etched, and phosphoric acid is the recommended method, and then rinsed in clean water, dried, and then painted with an etch primer.

If you do not wish to pre acid-etch, a possible viable primer is a two part epoxy etch primer – the rate of cure is much slower than the fast dry spray can stuff, and the etch has some time to occur – BUT the aluminium must be scrupulously cleaned first! No oil, finger prints, etc.

If you dig through my numerous posts and photos of my machine refurbishments you will see I ended up painting many aluminium parts, panels, etc, and these have to stand up to lathe and mill swarf, coolant, cleaning fluids, etc – and they do! These were all acid-etched first before priming and painting, after trying many other of-the-shelf 'solutions' that simply did not work.

If your application is decorative rather than hands-on functional, that spray can of stuff may just do the job!

The Phosphoric acid I use is actually a drain cleaner from the local hardware store – A 30% acid solution, and I put some in a plastic spray bottle – the kind you use to mist plants leaves, or spray liquid insecticides or whatever, and spray the metal surface till wet. Don't spray with too fine a mist setting – rather have large droplets , else the mist goes everywhere and burns your skin and clothes…

I first clean the metal with a liquid soap, a sponge, and water. Rinse, let dry a little, and then spray the acid on. The surface goes a milky white – leave for about 5 minutes – if any surface still shows shiny, add more acid – if the shine persists, then that area is oily so scrub it with a pot scourer for a few seconds. When all milky, rinse with clean water after 5 minutes, and dry – compressed air works well, or with lint free towels. Now an acid etch primer is good..PRIME RIGHT AWAY!

Use nitrile, or latex gloves – I use Housewives dishwashing gloves, the type that goes almost up to the elbow.

If the job is small, you can just dip the part in the acid container, keeping mess to zero, and no spray mist.

If parts are large – DO THIS OUTSIDE, unless you want the rest of the workshop to rust from the deposited acid mist and wear goggles or a face helmet, like those used by Grinders..

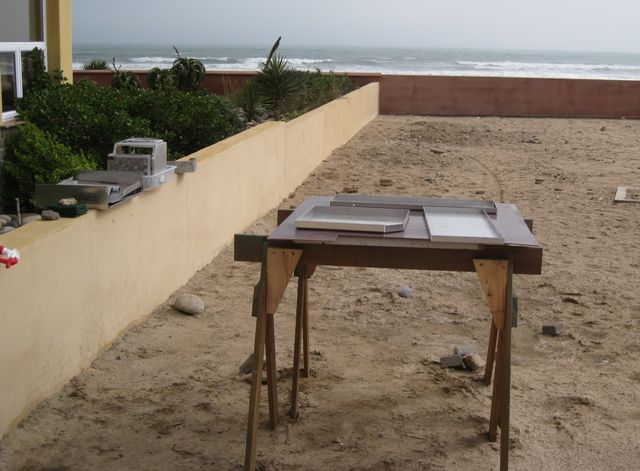

Here's where I did the acid etching…

Joe

And the Painted Parts..

the artfull-codger.

.jpg)