…

The question i really want answered is if I use Oxy-Acetylene for silver soldering the boiler stays particularly in the fire box would a 10 litre bottle of each be sufficient or do you need different sizes for oxygen and acetlylene? I have a 3 1/2” Molly boiler half completed and will also need to do the stays.

Thanks

Brian

The smallest size acetylene bottle that Hobbyweld do is 5 litres. That would be plenty for what you want. The smallest oxygen is about 10 litres which would be fine. Whatever sizes you have, they won’t do anything as convenient as running out at the same time.

…

I think the hazards of acetylene may be slightly exaggerated above; at one time (maybe not so much now) every garage, scrapyard, etc had oxy-acetylene equipment, and they rarely had anything terrible happen (If it was that dangerous, I’d have probably blown myself up long ago). Which isn’t to say you shouldn’t treat it with respect, of course.

…

I couldn’t answer Brian’s question, having no idea how much silver-soldering is needed to make a 3½” Molly Boiler, or how much Acetylene and Oxygen are contained in 10 litre bottles – it’s not 10 litres!

Therefore Andy’s assurance a 5 litre bottle of Acetylene is sufficient is valuable – it’s based on practical experience of similar work.

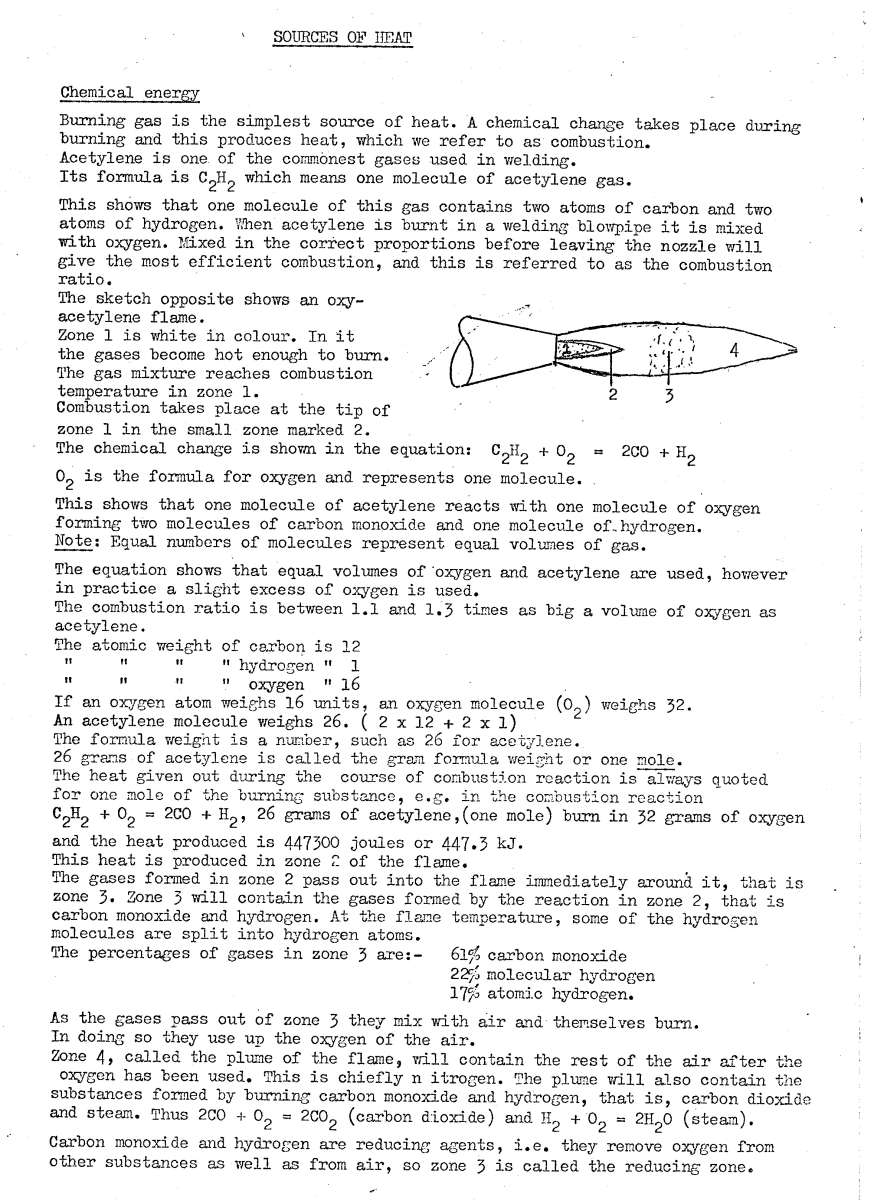

Nicholas gives a good intro to the theory, answering how much Oxygen is needed to burn Acetylene, ie the most efficient mix; minimum waste and the highest temperature. The calculation is done by weight, not volume, and I don’t know the weight of Acetylene stored in a 10 litre cylinder:

- The cylinder capacity is less than 10 litres because it contains a porous core.

- The Acetylene is dissolved in Acetone.

- The Acetylene is compressed.

Though simpler, I don’t know how much Oxygen is compressed into a 10 litre cylinder. Although there is no core or solvent taking space inside an Oxygen cylinder, the gas is compressed, so the answer depends on pressure.

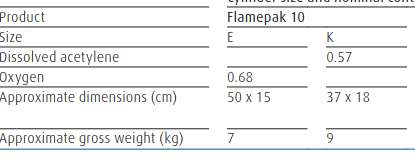

The British Oxygen site offers some clues in that they sell Acetylene and Oxygen together as a set, giving details of both bottles:

From this, we see BOC expect an average Oxyacetylene customer to burn 0.57 cubic metres of Acetylene in 0.68 cubic metres of Oxygen, which agrees with Nick’s post. They probably expect the average customer do be doing a mix of cutting and welding: more Oxygen is needed for cutting.

BOC’s cylinders are different shapes, maybe so they don’t get mixed up, maybe because the inert core needed inside an Acetylene bottle fits better into a squat cylinder, dunno.

BOC give approximate cylinder dimensions, from which I estimate their volumes as: Oxygen 8.8litres, Acetylene 9.4litres. This suggests Brian only needs single bottles of each assuming the other supplier is similar to BOC. Order one 10 litre bottle Oxygen with one 10 litre Acetylene, not 2:1 or some other ratio.

On the safety question, Andy accidentally highlights a major cause of accidents. It is that long incident free usage creates a false sense of security. Having ‘got away’ with sloppy bad practice for a few years, individuals tend to conclude that H&S precautions are unnecessary. They’re wrong! Just because an individual has successfully overtaken lorries on a blind bend 10 times does not mean it’s safe: statistics show that overtaking on a blind-bend is downright risky – luck, not judgement.

Interesting accident report here on the 2010 Bootle refilling plant explosion. Bootle had operated without incident for 90 years, and developed some bad habits. Despite 90 years of good news, it wasn’t safe. As usual with accidents, a number of different errors had to align, and one day they did.

H&S is about acting to make these alignments difficult. Not just common sense, or relying on previous experience, it’s necessary to remain alert, keep up-to-date, and apply current best-practice. Rarely difficult, basically just requires someone to list what could go wrong, what could be done to mitigate the risk, and what needs to be done if the worst happens. Thinking isn’t that difficult, or is it?

One Sunday a friend of my dad’s climbed onto his roof to fit a TV aerial to the chimney, which he did successfully. His family were out for the day. Halfway through the job it started to drizzle. Turning round to climb down he was faced with a steep pitched slippery roof and the need to climb backwards onto a ladder. Going down was much more dangerous than climbing up! He sat straddling the ridge yelling for help. Much later, a passer-by heard him and called the fire-brigade. By the time they turned up he was completely soaked.

Worse, the fire-brigade drew a crowd and a local journalist. Huge humiliation: the crowd loudly said he was a fool, on the ground he was privately bollocked by the Firemen who pulled no punches, later the story, with photos, was front-page news on the local paper, and he got a permanent nickname at work – ‘ladders’. Not difficult to think of a few simple ways he could have completed the job without the drama! At least he knew when to stop – many experienced roofers have come to grief in similar circumstances.

Oxyacetylene is much the same – safe enough if managed thoughtfully, and not too difficult.

There are always edge cases, where I think it reasonable for individuals to decide. Andrew J mentioned one, which is transporting acetylene laid flat in a car or van. This has caused a few nasty accidents, first because laying flat increases the risk of polymerisation; second because a small leak turns a confined space into a bomb. Although such accidents are extremely rare, it’s much safer to transport cylinders upright on the back of an open lorry. That’s inconvenient and expensive when it’s not particularly risky to move a cylinder a short distance in a private car, so why not?

Although illegal in some countries, it’s allowed in the UK as far as I know. I’d do it. Unfortunately some UK suppliers aren’t willing to risk their cylinder being involved in an accident because of the cost and hassle it will cause them. There will be trouble if they knew a customer wasn’t following “best-practice”. Much worse foolishness with Acetylene in a workshop doesn’t matter because suppliers don’t know about it or have any responsibility for the consequences.

Dave

KWIL.