Posted by Michael Gilligan on 02/11/2022 20:19:14:

It depends a lot on the strength of the material, Keith

…

Much thought and practical experience has gone into the design of the humble nut and bolt. Early heads were square because they and the spanner are both easy to make by hand, but the form is weak, the corners easily damaged, and the sharp edges gouge the material underneath. And only having 4 corners makes it harder to fit a spanner in a confined space.

Hexagon heads are better, the form supports the shoulders, the corners are harder to damage, and 6 edges are less likely to gouge than 4. Nonetheless, hex heads are relieved to reduce the risk, which unfortunately reduces the bearing area, which is bad news for soft materials, hence washers!

Whitworth was much influenced by the materials of his day. In the 1840s engineering materials were all relatively soft: cast-iron, wood, iron, wrought-iron, brass, copper, stone and brick etc. Steel was extremely expensive and unlikely to be used for ordinary fasteners. Does anyone know what Whitworth Nuts and Bolts were originally made of? My guess is mostly Iron until Bessemer steel changed everything 30 years later. Anyway, Whitworth's oversized heads made perfect sense when Queen Victoria was a teenager, but were an anachronism well before 1940 by which time steel bolts and washers were almost universal.

Although most fasteners today are standard there are plenty of good and bad reasons why a manufacturer might choose to be different. On the side of the angels tamper-proof fasteners are used to stop people undoing the wrong fixing, but they're also available to Satan to prevent simple home repairs. Cost cutting during manufacturing is another reason: on a production line, it might well be cheaper to fit a robot with a single socket and have it tighten a range of different bolts with non-standard heads. Mass-production has it's own logic, and they rarely care about men in sheds!

Bottom line though, the bearing area of a fastener should be big enough to prevent damage, including failure, of the material it's holding. The answer is usually a washer.

Dave

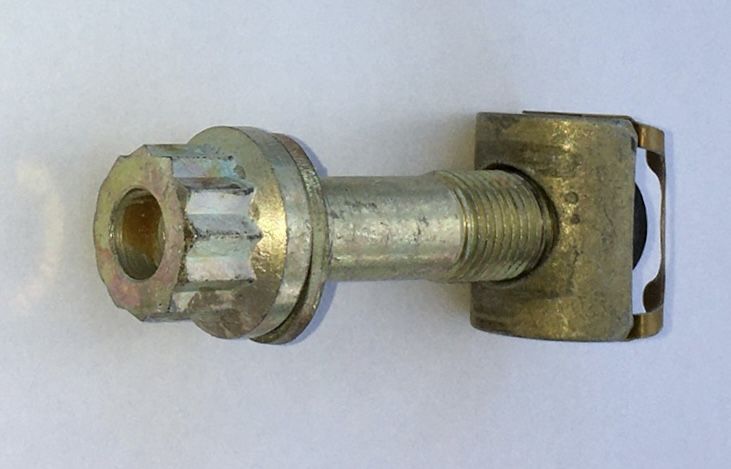

File Handle.

File Handle.