Firstly, apologies for not reading the thread, will be back later to read all. Scan reading, I don't think you have a solution, but I can see a few assembly errors, and youve missed a part that inside (it does need to come out, it will help you piece it together!)

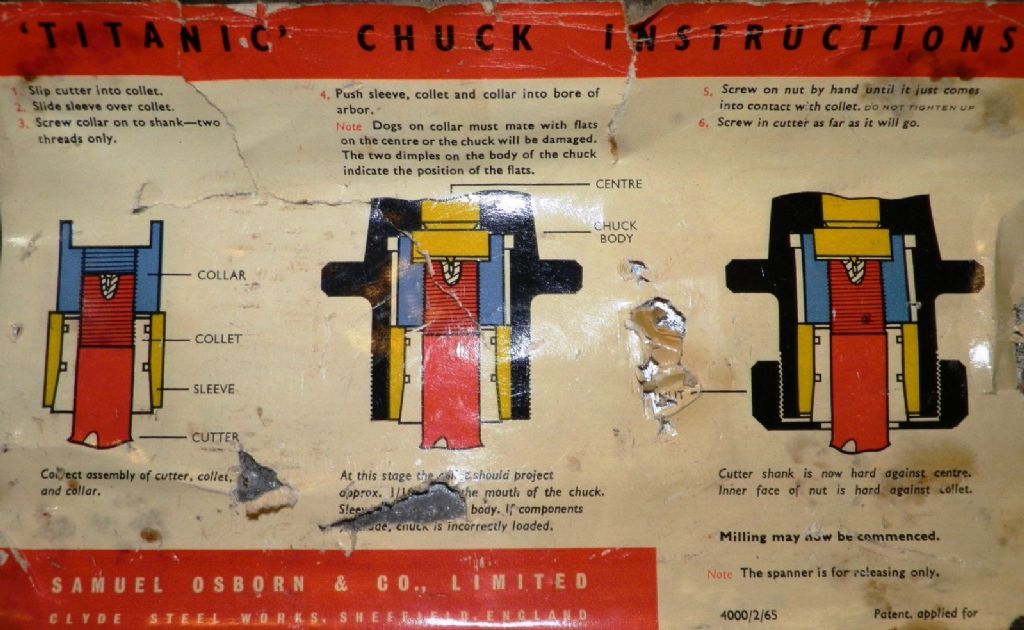

I have the same set, instructions are printed on the lid (or perhaps on a card in the lid) – I will have a look when I'm home and or photograph them if needed.

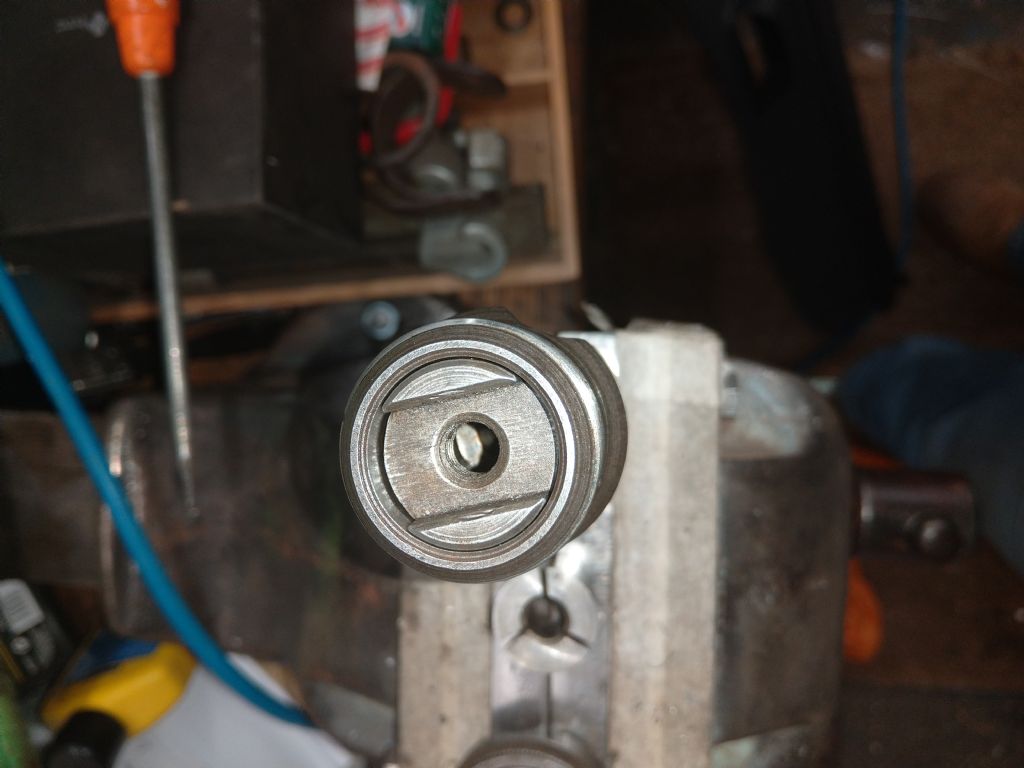

Observations…… your photo showing a view inside the chuck – there is a hardened steel outer ring in there, fish it out and it'll all start making sense, as will the following paragraph. Also note, that bit at the bottom with the point, has machined flats on it's OD, these engage with the notch in the threaded part….. which you've put in upside down in your photo, notch faces in, rotate till it engages.

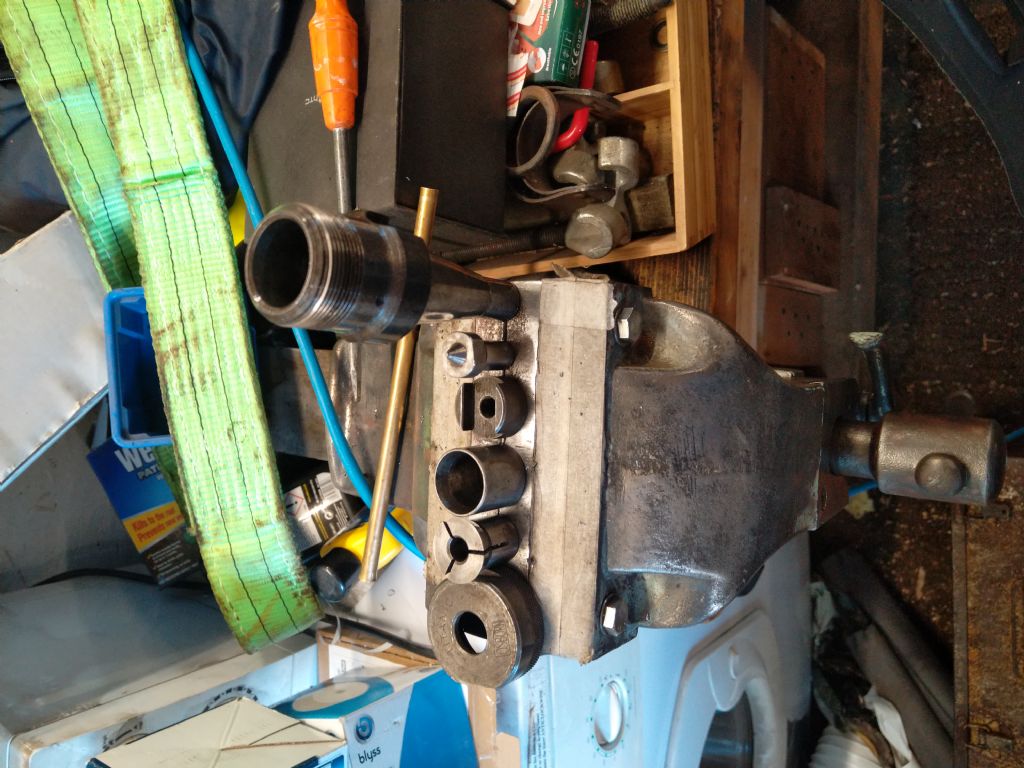

The shot of everything standing on the vice jaws, you collet is upside down, face the flared edge away from the notched/threaded part – the taper on the end engages with the taper in the hardened steel outer ring that you've left inside the body as per previous para..

The collet sits against the nut, as the endmill rotates, it does so against the hardened pin in the base, the notched/threaded part keying with the flats cannot rotate and the thread pushes it downward, which in turn pushes the hardened steel ring downward, this forces the outer tapered part to engage with the taper on the end of the collect, nipping the endmill.

I hope this makes sense, it's a bit rushed.

Edited By Russ B on 16/09/2022 10:12:02

Dave Weston.