The arbors I wanted are finally in stock so on Thursday I ordered a 50mm and 63mm facemill, a R8 and ISO40 arbor and 10 off of each insert type. The order was delivered on Friday morning.

The facemill and arbors are a nice slide fit and the inserts sit snuggly in the pockets. I haven't been able to try the 50mm face mill as one insert screw is missing, but I have been experimenting with the 63mm facemill this evening.

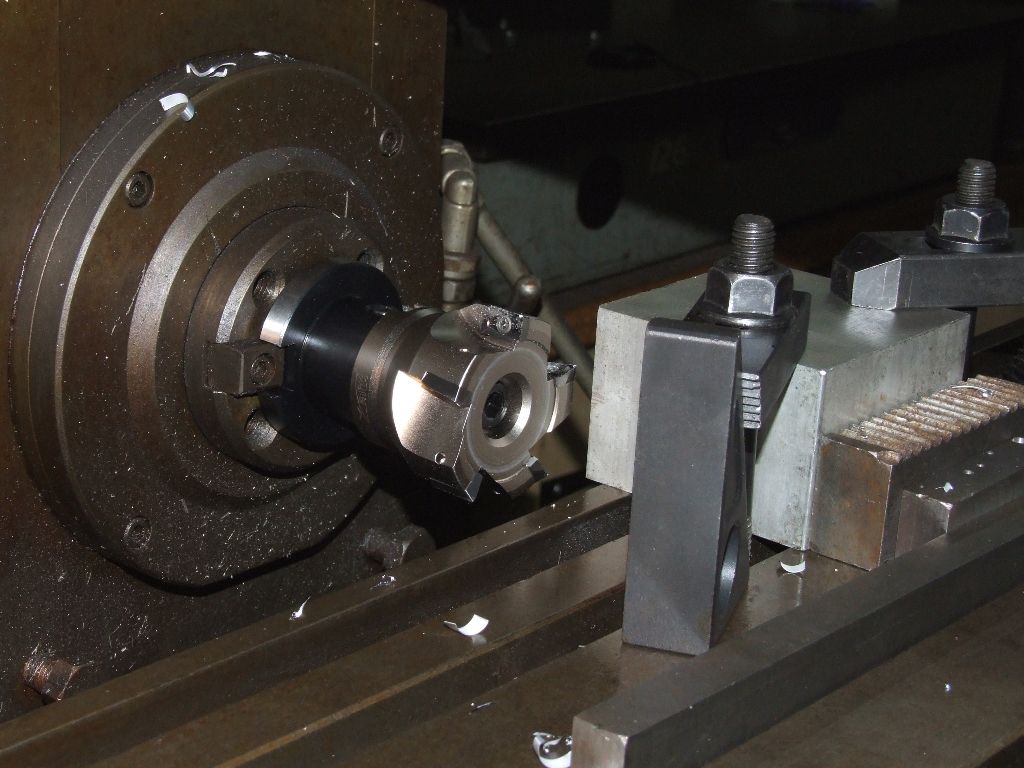

I used the ISO40 arbor on an Adcock and Shipley 2E universal horizontal mill. This is a solid mill at a bit under 2 tons with (in the high speed range) a 5hp motor driving through a geared spindle. First I tried 6082 aluminium with the ground and polished inserts. Here's the setup:

My mill is limited by feedrate, the maximum being 430mm/min. I wanted a chip load of about 0.1mm per tooth so (wiht 5 inserts on the facemill) I chose a spindle speed of 900rpm. I started cautiously with a cut of about 60mm wide and 1mm deep. The finish was good as shown here:

At one edge the surface roughness measured 1.04µm, in middle 2.07µm and at the other edge 1.05µm, all Ra. One would expect a variation across with width as the teeth cut at different angles across the width relative to the measurement. Next I went for broke with the same parameters except for the depth of cut which was now 4.5mm, as per the maximum recommended for the inserts. Roughness measurements at edge, middle and the other edge were 1.22µm, 1.66µm ad 1.06µm respectively.

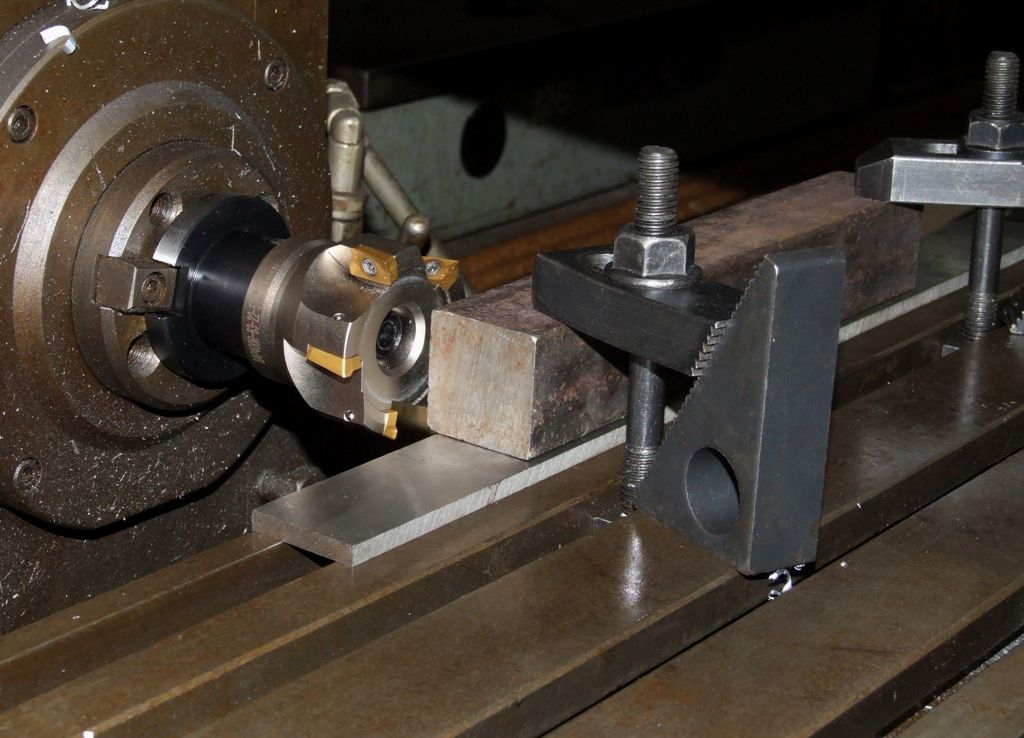

Next I tried hot rolled steel with the ordinary pressed inserts. Spindle speed and feedrate were the same, with a total width of cut of 40mm. Again I started with a depth of cut of 1mm. A similar setup was used:

Another good finish resulted, seen here:

Surface roughness measurements, specified as before, were 0.93µm, 1.49µm and 1.40µm. Finally I gave the facemill a run for it's money using the same cutting parameters as above, but with a depth of cut of 5mm. Surface roughness measurements were 1.15µm, 1.11µm and 0.91µm respectively.

Initial impressions of the facemills are excellent. in all cases the surface finish was good and very uniform. Surface roughness measurements are also consistent.

All cuts were very quiet with no discernable cutting noise and not a hint of chatter. Of course the milling machine is in the brick built outhouse category, which helps. But I'm beginning to wonder what on earth I have to do in terms of cutting parameters to test the mill to anywhere near it's limits.

Andrew

Edited By Andrew Johnston on 09/02/2020 22:40:32

JasonB.

JasonB.

![20200102_113407[1].jpg 20200102_113407[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/847776.jpg)